Ever pull on a favorite hoodie or pair of leggings and just marvel at how comfortable they are? That perfect stretch and give that makes clothing move with you is something we often take for granted. But it all started somewhere, and a big part of that story begins with the George C. Moore Company and its pioneering work in narrow elastics.

Their legacy is, in many ways, the foundation for what we know today as george moore sewing techniques. This guide will show you how to master those techniques, turning inspiration into tangible, wearable projects you can create at home.

The Legacy Behind Your Elastic Fabrics

It’s easy to forget that the comfy, flexible clothing filling our closets is the result of a century of innovation. Before stretchy fabrics became the norm, garments were often rigid and unforgiving. Think stiff collars and structured shapes that relied entirely on complicated tailoring. The arrival of narrow elastics was the secret ingredient that changed everything, giving sportswear its performance and our everyday clothes their incredible fit.

Knowing this history isn't just a fun fact; it’s the first step to really mastering your craft. To get the most out of these amazing textiles, you have to know what you’re working with. It all starts with understanding different fabric materials and their unique personalities. This foundation helps you pick the perfect textile for your project and know exactly how it’s going to act under the needle.

From Local Innovator to Global Leader

The George C. Moore Company's story is one of incredible focus and adaptation. It all began back in 1909 when George C. Moore started the company in Worcester, Massachusetts. For over a century—and now led by the fourth generation of his family—the company has stayed true to its mission.

What started as a regional American elastic maker has grown into a global leader with manufacturing in both the United States and El Salvador. That's some serious staying power. You can read more about the company's journey on themooreco.com.

This rich history of innovation directly impacts the fabrics we use today. Every time you sew a waistband or create a stretchy garment, you're building on a legacy that transformed how clothing fits, feels, and functions.

Here at bsewinn.com, we are committed to empowering crafters by transforming that legacy into practical skills. We provide the support and tools you need to create your own custom sewing machine designs with confidence. Our commitment includes:

- Custom Sewing Machine Designs: Created to help you replicate professional techniques on modern, stretchy textiles.

- Online Classes and Training: Guided instruction to help you master tangible skills for working with elastics on real-world projects.

- Extensive Resources: A full library of how-to guides and tutorials to support you at every stage of your creative process.

Why Narrow Elastics Changed Everything

If there's one innovation at the heart of the George Moore sewing legacy, it’s narrow elastic fabric. It's easy to take for granted now, but before these materials hit the scene, getting a garment to fit well was a real puzzle. Everything depended on a complicated system of darts, intricate seams, and ties to shape stiff, non-stretch fabric around the body.

Elastics brought a stunningly simple solution to the table. Suddenly, clothing could move with the wearer. It offered a kind of freedom that was completely new. Just try to imagine making a modern sports bra or a pair of leggings from basic cotton—it’s a perfect recipe for frustration and restriction.

This leap in comfort and function completely re-wrote the rules of clothing. The unique ability of elastic to stretch and snap back to its original shape made it essential for everything from simple waistbands to high-performance athletic wear.

A New Era of Garment Construction

The shift from pre- to post-elastic clothing isn't just a minor detail; it's a night-and-day difference. It marks a fundamental change in how we design, build, and wear our clothes, moving from rigid, structured shells to responsive, comfortable layers.

The introduction of elastic didn’t just add stretch; it gave designers and home crafters a new language for creating clothing that works in harmony with the human body. This is a core principle you can master.

This evolution is what makes it possible for us to create such comfortable, functional pieces from our own sewing rooms. At bsewinn.com, we focus on providing the custom sewing machine designs and online resources you need to tap into that power. Our training and support are all about helping you master these amazing materials, so you can turn your creative ideas into polished, professional-looking garments.

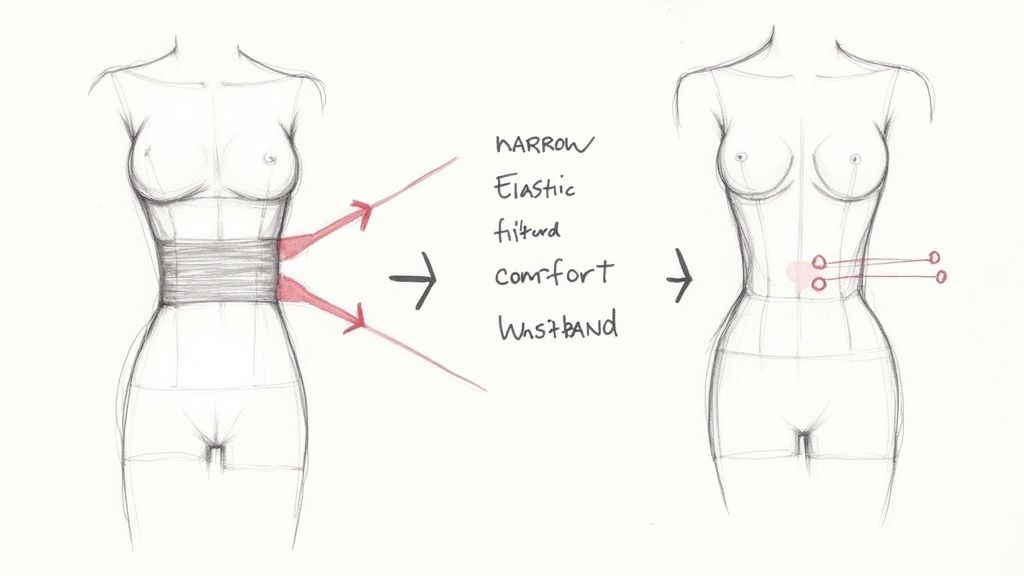

To really see the impact, let's look at a side-by-side comparison.

How Elastic Fabrics Transformed Garment Construction

| Garment Feature | Pre-Elastic Era (Early 20th Century) | Post-Elastic Era (Modern Day) |

|---|---|---|

| Fit | Relied on darts, pleats, and ties for shaping. | Achieved with fabric stretch and recovery. |

| Comfort | Often restrictive, limiting natural movement. | Flexible, allowing a full range of motion. |

| Construction | Required complex and time-consuming tailoring. | Simplified with casings and direct application. |

| Closures | Dependent on buttons, hooks, and laces. | Often pull-on, with no closures needed. |

It's clear that the arrival of narrow elastics didn't just add a new material to our sewing kits—it unlocked a whole new philosophy of making clothes.

Mastering Sewing Techniques for Stretchy Textiles

Alright, let's talk about sewing with stretchy fabrics. Working with knits and elastics can feel a little intimidating at first, but it's a skill that totally changes the game, giving your projects a much more professional finish. This is where we shift from the "why" and get into the "how." By nailing a few core George Moore sewing principles, you can take on those stretchy materials with confidence.

The end goal is always to create garments that not only fit like a dream but are also built to last. It all comes down to technique. Little skills, like making a clean elastic casing or applying elastic directly with a zig-zag stitch, make a world of difference. And if you're just starting, it's always a good idea to spend some time exploring fabric types to understand how they behave and feel.

Don't worry, each of these techniques is designed to be totally manageable for the home sewist. It's all about turning potential sewing frustrations into a truly rewarding process.

Core Skills for Elastic Application

To get started, let’s focus on two basic methods for sewing with elastic. They each have different uses, but both are essential additions to your sewing toolkit.

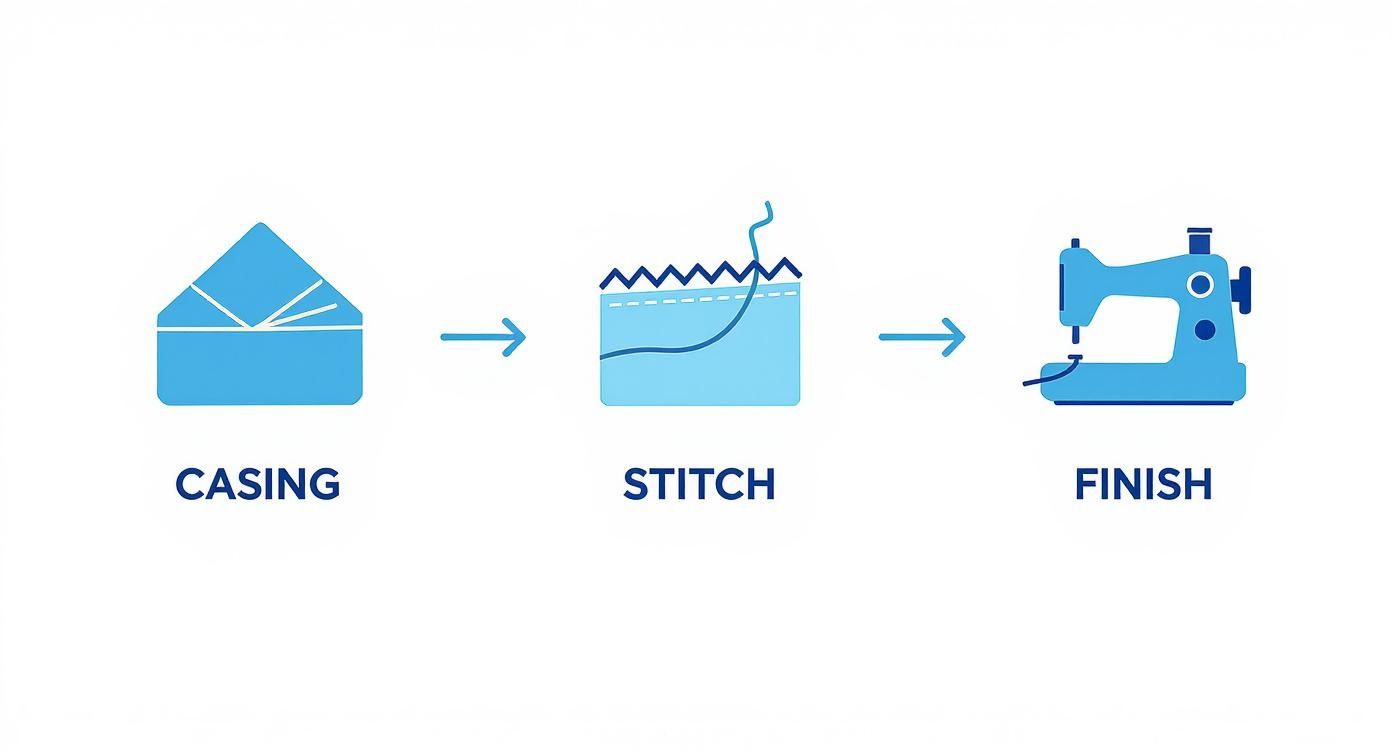

- Creating an Elastic Casing: This is the classic way to do waistbands on things like pajama pants or simple skirts. You just fold over the fabric's edge, stitch it down to make a little tunnel, and then thread your elastic through. The real trick here is making sure the casing is just a smidge wider than your elastic—that’s what keeps it from twisting and bunching up inside.

- Direct Zig-Zag Application: For a quicker, more streamlined finish, you can stitch the elastic right onto the fabric's raw edge with a zig-zag stitch. This method is amazing for activewear and undergarments because it delivers fantastic stretch and recovery without adding any extra bulk.

Think of these two skills as your foundation for tackling any stretchy project. If you're ready for a deeper dive into settings and different stitches, you should definitely check out our guide on how to sew stretch fabrics.

This is where the bsewinn.com philosophy of empowering crafters really comes to life. Our custom machine designs and online training are built to help you master these exact skills. It’s about giving you the confidence to get a flawless, durable fit every single time. We’re here to be the support system you need to turn ambitious ideas into wearable art, right from your home sewing machine.

How-To Guide: Your First Elastic Fabric Project

Alright, you’ve got the basics of George Moore’s techniques under your belt. Now it’s time for the fun part: putting it all into practice. This how-to guide will walk you through creating a tangible, wearable garment you can be proud of.

We're going to create a simple, satisfying project—a comfortable bralette. It's the perfect way to replicate professional techniques and see how those principles work in the real world, especially since elastic is the star of the show here.

Think of this as a complete roadmap. With our custom designs and guidance, we'll turn a piece of fabric into a high-quality item, building your skills and confidence one stitch at a time.

Project Prep: The Bralette

As any seasoned sewist will tell you, the secret to a great result happens before you even sit down at your machine. A little prep goes a long way.

- Select Your Fabric: For a project like this, you want a knit fabric with good stretch and recovery. Something like a cotton-spandex blend or a bamboo jersey is perfect—they’re forgiving to work with and feel great against the skin.

- Choose Your Elastic: You'll need a soft, decorative elastic for the bottom band. A good rule of thumb is to measure your underbust, then subtract 2-3 inches. This gives you a snug, supportive fit that isn't too tight.

- Pattern and Cutting: Grab a simple bralette pattern. Be sure to pay attention to the direction of greatest stretch when you lay out your fabric. Cut your pieces carefully and transfer all your markings.

Once you have all your materials ready to go, we can start the fun part—construction.

The infographic below breaks down the key steps for applying elastic. It's a great visual reminder of how to create a clean channel and use a consistent stitch for a polished look.

See? A clean casing and a steady zig-zag stitch are all it takes to get that professional finish.

Assembling Your Garment

Let’s get this thing stitched together! Follow your pattern instructions to sew the bralette cups and any side seams first. Then, take your pre-cut elastic band, overlap the ends just slightly to form a circle, and secure them with a zig-zag stitch.

This project is a fantastic way to practice applying elastic directly. You'll gently stretch the elastic as you sew it to the bralette's bottom edge, which creates that secure, flexible band that moves with you.

Use a zig-zag stitch to attach the elastic band to the bottom edge of your bralette. If you want to make this step even easier and get a perfectly even feed, a specialized presser foot can be a game-changer. In fact, we offer an elastic foot for VIVANT that makes this part of the process incredibly smooth.

All that's left is to add your straps, and you’re done! You’ve just made a beautiful, custom-fit bralette.

How Innovation Inspires Sustainable Crafting

When you look at the principles behind the George C. Moore legacy, you can't help but see how relevant they are today—especially when it comes to sustainability. The core idea is simple but powerful: quality and mindful production are two sides of the same coin.

This isn’t some high-level philosophy just for big factories. It’s a mindset we can bring right into our own sewing rooms.

Choosing better materials, mastering efficient techniques—these are ways we can honor a history of innovation while making our craft more responsible. It’s a really satisfying way to connect your creative passion with the bigger picture of making a difference.

You can see this approach in action within the industry, too. The George C. Moore Company, for instance, made huge strides in reducing its environmental footprint. They slashed heating and cooling energy use by 35%, cut lighting energy by 40%, and lowered water usage per yard by a whopping 44%. You can learn more about their environmental initiatives on georgecmoore.com. It just goes to show that a real commitment to responsibility gets real results.

Bringing Sustainable Practices to Your Sewing Room

Adopting a more mindful approach doesn't mean you have to completely overhaul your craft room overnight. It really just starts with small, intentional choices that add up over time.

Take your tools, for example. Modern sewing machines are engineered for much better efficiency than their older counterparts. Even the choice between different models can affect how much energy you use and how smooth your workflow is. Our guide on computerized sewing machines vs mechanical ones gets into some of those differences.

Every choice, from picking a durable fabric that will last for years to saving those little scraps for a future project, is part of a more sustainable practice. It’s all about creating with intention and respecting the resources you’re using.

Here at bsewinn.com, we champion this mindset by empowering you to create beautiful, high-quality garments that last. Our online classes and custom designs are here to help you sew with precision, which means less waste and more pieces you'll truly cherish.

Your Top Questions About Sewing With Elastics

Let's tackle some of the most common questions that come up when we talk about the George Moore sewing legacy and the real-world challenges of wrangling elastics.

What's the Best Stitch for Applying Elastic?

Your absolute best friend here is a zig-zag stitch. Think about it—the stitch itself has a natural stretch and give, moving with the fabric instead of fighting against it. This built-in flexibility is what keeps your threads from snapping the second you stretch the garment.

If you're aiming for a finish that looks like it came straight from a high-end store, a serger or overlocker is the way to go. It’s a fantastic tool because it stitches, trims excess fabric, and neatens the edge all in one clean pass.

How Do I Stop Elastic From Twisting Inside a Casing?

Ah, the dreaded twisted elastic! It's a frustrating problem, but thankfully, the fix is pretty simple. First, make sure the casing itself is just wide enough for the elastic to pass through snugly. Too much wiggle room is an open invitation for it to flip and twist.

Once you've threaded the elastic through, lock it down by stitching vertically right across the casing, usually at the side seams. This technique is often called "stitching in the ditch," and it's a game-changer. That one little step anchors the elastic in place for good.

When you start to understand the history behind materials, like the narrow elastics that George C. Moore perfected, you gain a deeper appreciation for their unique properties. It connects you to a long tradition of quality and inspires you to really master the techniques needed for durable, beautifully made clothing.

Where Can I Find Designs and How-To Guides for Sewing With Elastics?

You're in the right place! Here at bsewinn.com, our mission is to empower crafters like you. We offer a whole collection of custom sewing machine designs and online classes that were created specifically for modern stretch fabrics. Whether you're diving into activewear or delicate intimates, our comprehensive how-to resources are designed to walk you through each project for a professional-quality result every single time.

At B-Sew Inn, we are committed to empowering crafters by providing the tools, training, and community you need to make your sewing projects a success. Explore our custom sewing designs and extensive library of resources to get started on your next creation. Find everything you need to bring your ideas to life right here at https://www.bsewinn.com.