When your sewing machine—your trusted creative partner—starts acting up, that sinking feeling is often followed by a big question: "What's this going to cost me?" It's a fair question, and the answer isn't always a simple one. Generally, you can expect a sewing machine repair to cost anywhere from $50 to over $100, but that depends entirely on what's going on under the hood.

A minor tune-up might land on the lower end of that scale, while a serious mechanical meltdown or electrical issue will obviously cost more. At B-Sew Inn, our goal is to empower you not just with custom sewing machine designs, but with the knowledge to care for them. Understanding these costs is the first step to making a smart decision for your machine and keeping your projects on track.

Decoding Sewing Machine Repair Costs

We've all been there. Your machine starts skipping stitches, making a weird clunking noise, or the tension just won't cooperate. The last thing you want is a surprise bill that costs more than the machine itself. The final price tag for a repair can swing pretty wildly based on your machine's type, how bad the problem is, and even where you live.

Looking at recent numbers from across the United States, the average repair falls somewhere between $50 and $100. The sweet spot, or median price, is right around $75. This usually covers common frustrations like a thorough cleaning to remove jammed-up thread or a simple tension adjustment.

Of course, if you're sewing on a high-end embroidery machine or a beloved vintage model, the costs can climb. These machines often need specialized parts or a technician with a very specific set of skills, which naturally pushes the price up. To get a better feel for what goes into the final cost, you can find more detailed pricing information that breaks down all the influencing factors.

Estimated Sewing Machine Repair Costs at a Glance

To give you a clearer picture of what you might be looking at, here's a quick cheat sheet for some of the most common repairs. Think of it as a guide to help you budget before you even walk into the shop.

| Type of Repair or Service | Estimated Cost Range |

|---|---|

| Basic Tune-Up & Cleaning | $50 - $85 |

| Tension Adjustment | $60 - $95 |

| Timing Recalibration | $75 - $125 |

| Motor Replacement | $100 - $200+ |

| Computerized Board Repair | $150 - $300+ |

Keep in mind these are just estimates! The final bill will always depend on your specific machine and the shop's labor rates. It's always a good idea to get a quote upfront.

At B-Sew Inn, we believe in empowering crafters with knowledge. Understanding potential repair costs is crucial for maintaining your creative tools without breaking your budget. Our commitment is to provide the support and extensive resources you need, from online classes to expert training, to keep you sewing confidently.

What Drives Your Final Repair Bill

Ever look at a repair bill and wonder how the final number came to be? One simple fix might cost $50, while another seemingly small issue on a different machine rings up at $200. The final cost of a sewing machine repair isn’t just a random number a technician pulls out of a hat—several key factors directly influence what you'll end up paying.

Think of it like this: getting a basic mechanical machine serviced is a lot like a routine oil change for your car. It's straightforward, predictable, and doesn't require a ton of specialized diagnostics. But servicing a high-end computerized embroidery machine? That's more like a mechanic trying to fix the complex electronics in a brand-new luxury vehicle. The intricacy of the machine itself is probably the single biggest driver of your final bill.

Key Factors Influencing Repair Costs

Beyond the machine's complexity, a few other elements come into play. A simple tune-up, for instance, will always cost less than having to replace a completely burnt-out motor or a cracked gear. The severity of the problem is always the first thing a technician has to diagnose before they can even think about giving you a quote.

Here are the main things that determine what’s on your invoice:

- Machine Type: A good old mechanical machine has fewer moving parts and is almost always less expensive to fix than a computerized model packed with circuit boards and delicate sensors.

- Brand and Model: Getting parts for popular, current brands is usually easier and more affordable. Finding a specific part for a rare or vintage machine can be a real treasure hunt, and the cost will reflect that.

- Severity of the Issue: A basic tension adjustment is a quick job for an experienced tech. Diagnosing and fixing a persistent timing problem that has everything out of whack? That takes a lot more time, labor, and expertise.

- Geographic Location: This one might surprise you, but labor rates can vary quite a bit from one city to another. A repair in a major metro area will likely cost more than the exact same job in a smaller town.

This trend is something we see across the entire sewing world. As machines get more and more advanced, the cost to keep them running smoothly naturally goes up because the repairs demand specialized skills and parts.

Knowing what goes into a repair bill is the first step to becoming a more empowered machine owner. When you have a good idea of why a bill might be higher, you're in a much better position to decide if a repair is the right financial move.

For example, specialized machines like sergers almost always require more intricate servicing. If you're running a high-performance model, like a pre-owned Baby Lock Accolade serger, you’ll want a technician who really knows their way around its specific mechanisms, and that expertise can definitely influence the cost.

Deciding Between DIY Fixes and Professional Help

Every sewist eventually faces the "fix it myself or call for backup?" dilemma. Learning to tell the difference is a skill that not only saves you money but also builds a deeper connection with your machine. After all, many of the most common sewing frustrations are actually perfect for a DIY fix, stopping a small annoyance from turning into a project-killing disaster.

Simple things are often the culprit. Taking a moment to clear out lint buildup, tweaking the thread tension, or even just re-threading the machine can get you back on track. A fresh needle is another superstar fix—it's amazing how many stitch problems a dull or bent needle can cause. If you're not sure which one to grab, our guide on choosing the right needle is a great refresher. Mastering these little maintenance tasks is empowering and keeps your machine humming along happily.

But sometimes, the problem is bigger than a quick tune-up. There are definite red flags that signal it's time to step away and let an expert take a look.

When to Call a Professional

Trying to force a fix on a complex mechanical or electrical issue without the right tools and training can quickly turn a small problem into a very expensive one. It’s absolutely time to call in a technician if you notice any of these signs:

- Loud Grinding or Clunking Noises: That's not a happy sound. It often points to a problem deep inside with the gears or motor, things that shouldn't be messed with unless you know exactly what you're doing.

- Electrical Problems: If you smell something burning, see a wisp of smoke, or the machine is completely dead and won't power on, unplug it immediately. This is non-negotiable—call for service.

- Persistent Timing Issues: Is your thread constantly tangling or are you getting skipped stitches no matter what you do? This often means the timing is off—the delicate dance between the needle and the bobbin hook is out of sync. This requires precise calibration that's best left to a pro.

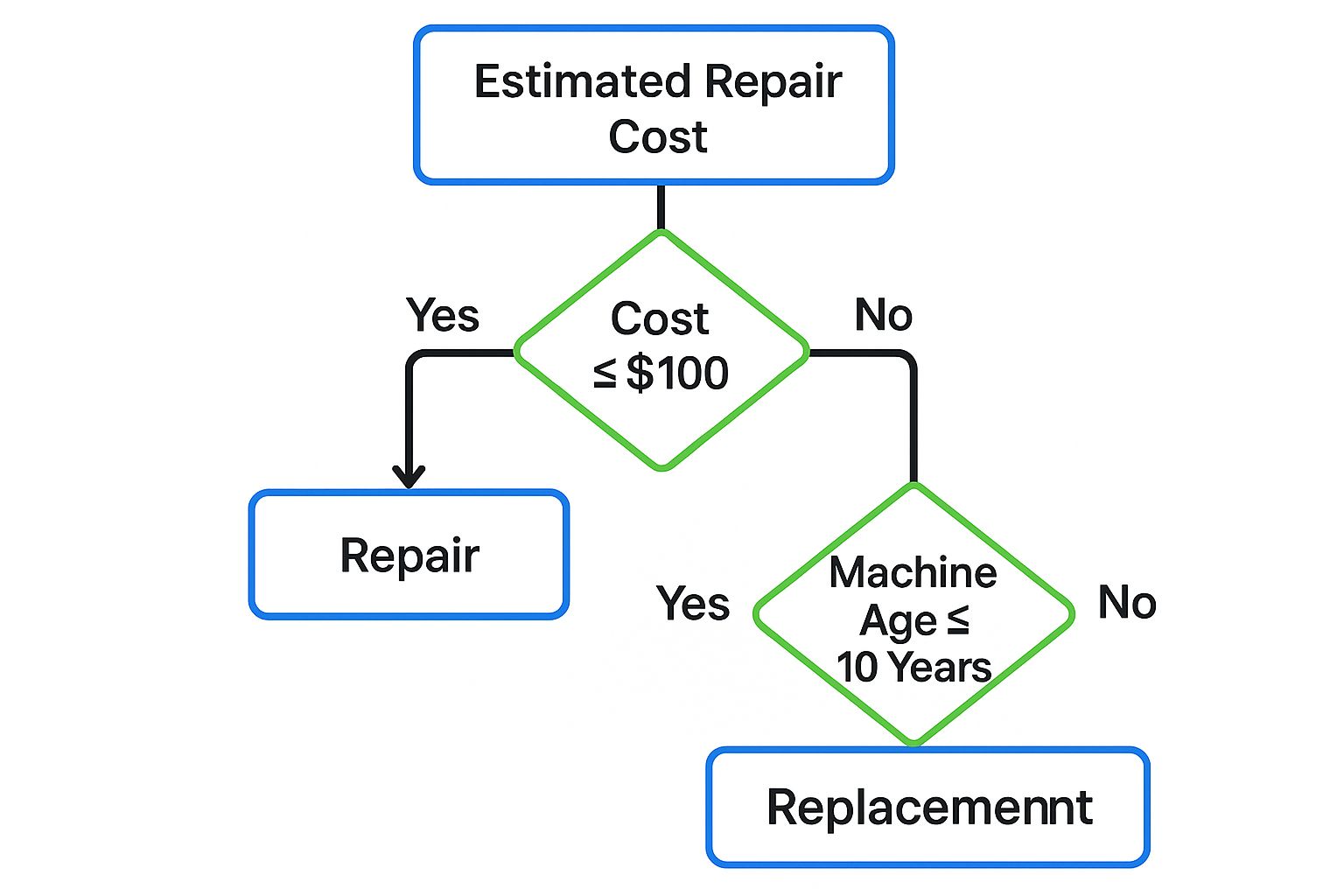

This handy chart gives a good visual for when it makes sense to repair versus when you might need to think about replacing your machine, based on its age and the potential cost.

As you can see, for a newer machine with a reasonable repair estimate, getting it serviced is almost always the smarter financial move.

To make things even clearer, here’s a quick-glance table to help you decide on your next move.

Should You DIY or Call a Pro?

| Common Sewing Machine Issue | Recommended Action (DIY or Pro) | Key Considerations |

|---|---|---|

| Skipped Stitches | DIY First | 9 times out of 10, this is a needle issue. Swap it out for a new one. Also, check your threading. |

| Thread Bunching Under Fabric | DIY | This is usually a tension or threading problem. Re-thread your machine completely (top and bobbin). |

| Loud Grinding/Clunking Noises | PRO | These sounds often signal internal mechanical issues that require disassembly and specialized tools. |

| Machine Won't Turn On | PRO | After checking the outlet and power cord, this is an electrical issue that needs an expert. |

| Uneven Stitches | DIY | Check your needle, thread tension, and make sure you're using the right presser foot for the job. |

| Timing is Off | PRO | Resetting the machine's timing is a delicate adjustment that can be made worse if done incorrectly. |

Ultimately, knowing your machine is your best guide. Trust your gut—if a problem feels too big or too complicated, it probably is. There's no shame in calling for professional help to protect your investment.

A Whole Different Ballgame: Industrial Sewing Machine Repairs

If you're running a small business or you're a serious maker, you already know that an industrial sewing machine isn't just a beefed-up version of a home model. These things are the workhorses of production, designed from the ground up for speed, power, and the ability to chew through tough materials all day long. So, it shouldn't come as a surprise that the cost of sewing machine repair for these machines is on a completely different level.

Think of it like this: getting your industrial machine serviced is like taking a commercial truck to the shop, whereas your home machine is more like the family car. The parts are bigger, tougher, and built to withstand constant, heavy use—and that means they cost more to replace. On top of that, the technician working on it needs a very specific skill set to figure out what’s wrong with these complex systems, from the high-powered motors to the intricate automated functions. That specialized expertise is a huge part of the final bill.

Why It's an Investment, Not Just a Cost

Beyond the price of parts and a technician's time, the real hidden cost is downtime. When your industrial machine is on the fritz, it’s not just an annoyance. Every hour it sits idle is an hour of lost production, which translates directly to lost revenue. That's why professional, regular maintenance isn't just an expense; it's a core part of your business strategy.

The numbers back this up. The global industrial sewing machine market hit a value of USD 3.01 billion in 2023, and it's set to keep growing, especially with the rise of automation. As these machines get smarter and more complex, the demand for skilled technicians and high-quality parts only goes up. It really highlights how crucial professional service is to protect your investment. You can read more about this trend and its impact on maintenance needs.

At bsewinn.com, we understand this dynamic perfectly. We know our custom sewing machine designs are often the heart of a small business. That’s why our support, from extensive online training to a deep well of resources, is designed to empower you with the skills to keep your machine healthy and your creativity flowing.

When you understand what goes into these repairs, it's easier to budget for them and view maintenance as the essential business function it is. It's all about ensuring your equipment lasts and your creativity never has to stop.

How Regular Maintenance Saves You Money

Let's be honest, the best way to deal with a hefty sewing machine repair bill is to avoid it in the first place. A little proactive care is your absolute best defense against those unexpected breakdowns that always seem to happen right in the middle of a project. Seriously, investing just a few minutes in a simple maintenance routine can save you hundreds of dollars down the road.

Think of your sewing machine like you would your car. You wouldn't skip oil changes and just wait for the engine to seize, right? It's the same idea here. Small, consistent actions are what keep your machine humming along and prevent the common little issues from snowballing into expensive service calls. It's all about shifting from a "fix it when it breaks" mindset to one of proactive care.

Your Simple Maintenance Checklist

You don't need to be a certified technician to keep your machine in good shape. A basic but incredibly effective routine is easy to get into and targets the most frequent causes of machine trouble, keeping you in creative control.

Here’s a simple checklist to get you started:

- Regular Cleaning: After every few projects, take a moment to brush out lint and dust from around the bobbin case and feed dogs. You'd be shocked how much builds up! Lint buildup is the number one culprit behind tension problems and skipped stitches.

- Proper Oiling: Just a single drop of high-quality sewing machine oil on the key moving parts makes a world of difference, reducing friction and wear. Your machine’s manual is your best friend here—it'll show you exactly where to apply it for the biggest impact.

- Timely Needle Changes: A dull or bent needle is bad news. It can damage your beautiful fabric and put a real strain on your machine’s motor. I make it a habit to start every big new project with a fresh needle. It's a cheap and easy rule to follow.

Sticking to a simple maintenance schedule like this is genuinely empowering. You're taking charge of your machine's health, turning yourself from just a user into a confident owner who can troubleshoot and maintain their most important creative tool.

This proactive approach is crucial for any machine, whether you're working on a basic starter model or something more advanced like the Baby Lock Joy sewing machine. Here at bsewinn.com, our goal isn't just to sell you a machine; we want to empower you with the training and resources you need to keep it running in peak condition for years to come.

Take Control of Your Craft with Knowledge and Support

Truly mastering your craft is about more than just creating beautiful things—it’s about knowing your most important tool inside and out. Learning to handle basic maintenance yourself, and knowing when a pro is needed for a trickier fix, doesn't just cut down on the overall cost of sewing machine repair. It builds your confidence.

This is a complete shift in mindset. You're no longer just a person who uses a sewing machine; you become someone who truly understands it.

Here at bsewinn.com, our commitment is to empower you on that journey. We believe that with the right tools and training, every crafter can feel totally in command of their machine. Our custom sewing machine designs are backed by extensive support to help you achieve just that.

Your Path to Machine Mastery

We've built our resources to go way beyond basic sewing tutorials. Our custom sewing machine designs come with a ton of support meant to help you get the absolute most out of your purchase. It’s the kind of support that totally changes your relationship with your machine.

Gaining the confidence to handle your own routine maintenance saves money, sure, but it also deepens the connection you have with your craft. What once felt like a frustrating problem becomes a chance to learn something new.

We're committed to empowering our community of crafters with resources like:

- Detailed Online Classes: Learn everything from quick troubleshooting tricks to more advanced maintenance, all from your own sewing room.

- Hands-On Training Materials: Our how-to guides provide clear, step-by-step instructions for common tasks and creative projects, taking the mystery out of how your machine works.

- An Extensive Resource Library: Got a question? We've probably got an answer. Dive into our support materials designed to keep you and your machine humming along happily.

Take a look around and start your journey toward becoming a machine expert. We’ll be here to support you every stitch of the way.

Got Questions? We've Got Answers

Is It Really Worth Repairing an Old Sewing Machine?

Oh, absolutely! This is especially true if you've got one of those older, all-metal mechanical machines. Those things were built like tanks. Often, all they need is a simple tune-up, which can run between $50 and $100, to get them stitching as good as new.

My rule of thumb is this: if the repair costs less than half the price of a brand-new machine with similar capabilities, it's a fantastic investment.

How Often Should I Get My Sewing Machine Professionally Serviced?

This really depends on how much you use it. If you're a hobbyist who pulls out the machine a few times a month, getting it looked at by a pro every one to two years is perfect.

Now, if you're sewing every single day or running a small business, you'll want to book an annual tune-up. Think of it as preventative care to head off any major, costly breakdowns before they happen.

What Does a Standard Sewing Machine Tune-Up Actually Include?

A standard tune-up is like a deep-clean and check-up for your machine. The technician will give it a full health check, which typically involves:

- Giving the interior a thorough cleaning to get rid of all that pesky lint.

- Oiling all the moving parts so everything runs smoothly.

- Checking and tweaking the thread and bobbin tension.

- Inspecting the belts and motors for any signs of wear and tear.

- Making sure the machine's timing is spot-on for perfect stitches every time.

At B-Sew Inn, we believe knowledge is the most important tool any crafter can have. Our commitment is to empower you with the custom designs, training, online classes, and extensive resources you need to truly understand your machine and master your craft. https://www.bsewinn.com