Starting a custom apparel business is a huge step, and your success hinges on having the right tools from day one. When you're hunting for the best embroidery machine for a small business, you have to think beyond the price tag. This machine needs to match your business goals, how much you plan to produce, and what you can realistically afford.

Think of it as hiring your most important employee—one that works tirelessly in the background. At bsewinn.com, we're committed to empowering your journey, not just by providing the machine, but by offering the support, online classes, and training to turn your creative ideas into replicable, profitable designs.

Launching Your Embroidery Business With Confidence

Choosing that first machine is a foundational moment. It’s the step that turns a creative hobby into a business that actually makes money. This guide is your roadmap, but we're going to go deeper than just tech specs. We’ll explore how the right machine becomes the engine for your financial and artistic growth, helping you find a partner that can keep up with your biggest ambitions.

Let's be real: the demand for personalized, unique clothing and accessories is booming. This is the perfect time to jump in. The global embroidery machine market was valued at around $2.54 billion and is only expected to grow, all thanks to people wanting cool, custom stuff. You can read more about the growing embroidery market and see the full analysis.

Here at bsewinn.com, we want to do more than just sell you a machine. Our goal is to give you a complete support system designed to help you succeed.

More Than a Machine—A Business Partnership

We believe our job doesn't end when you click "buy." Real confidence comes from knowing you’ve got a reliable partner to walk you through the learning curve and cheer you on. That’s why we’ve built a full suite of resources to back you up:

- Expert-Led Online Classes: Learn everything from the basics to advanced techniques with tangible examples you can replicate. Our classes show you how to create specific designs, like a perfectly centered chest logo on a polo or a complex floral pattern on a denim jacket.

- Comprehensive Training: Our hands-on training gets you comfortable with your machine fast, so you can master its features and handle common hiccups without breaking a sweat.

- Extensive Resources: You'll get access to a whole library of tutorials, design guides, and step-by-step projects to keep your skills sharp and the creativity flowing.

With the right support system, your new embroidery machine for a small business stops being just a piece of equipment and becomes the cornerstone of your success story. You can take on new projects, from simple monograms to complex, multi-color designs, without hesitation.

By pairing top-tier machines with dedicated support, we help you feel ready to go from your very first stitch. If you're ready to take the next step, our guide on how to start an embroidery business is a great place to get the full picture.

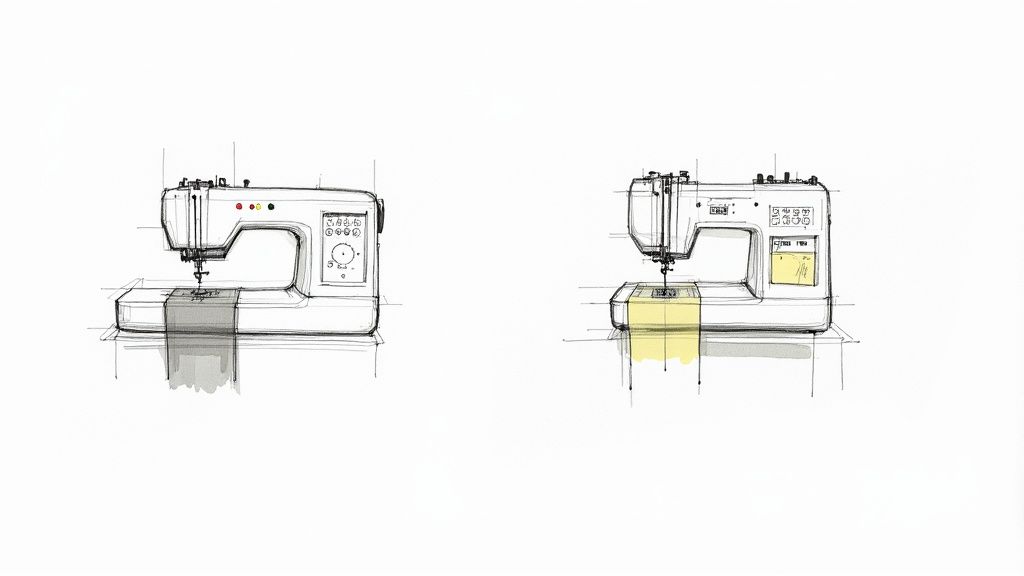

Choosing Your Machine: Single-Needle vs Multi-Needle

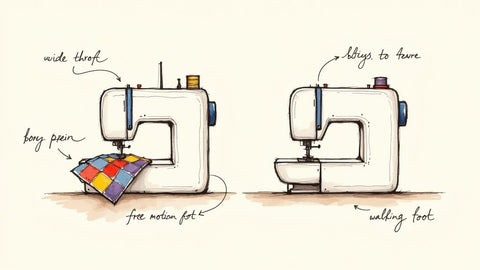

Picking the right embroidery machine is one of the biggest calls you'll make for your new business. The decision between a single-needle and a multi-needle machine will literally shape what you can produce, how fast you can do it, and how quickly you can grow. It’s a lot like choosing between a personal car and a commercial van for a delivery service.

A single-needle machine is your trusty sedan. It's perfect for those one-off, highly personalized jobs, like putting a monogram on a baby blanket for an Etsy order or creating a special gift. It does beautiful work, but you have to be hands-on, stopping to manually change the thread every single time a design calls for a new color.

On the other hand, a multi-needle machine is the big delivery van. This thing is a workhorse, built for volume and pure efficiency. It holds several spools of thread at once and automatically switches between them as the design dictates. That means you can churn out complex, multi-colored designs for bulk orders—think company polos or a whole set of team hats—without babysitting the machine for every color change.

How to Match the Machine to Your Business

The best machine for you comes down to your business goals. Are you planning to focus on low-volume, high-touch custom work? A single-needle machine is a fantastic, budget-friendly way to get started. I’ve seen countless successful home-based businesses get off the ground with one, building an amazing portfolio one beautiful piece at a time.

But if you're dreaming bigger—tackling large orders for local schools, sports teams, or corporate clients—a multi-needle machine isn't a luxury, it's a necessity. All that time you save from not having to manually change threads goes straight to your bottom line in the form of higher output and more profit. It’s an investment, but it’s an investment in your ability to scale.

The real deciding factors are your expected production volume, the complexity of your designs, and what you plan to embroider. Things like structured hats or thick jackets are tough on smaller machines. This isn't just about bells and whistles; it's about matching your equipment to your revenue goals.

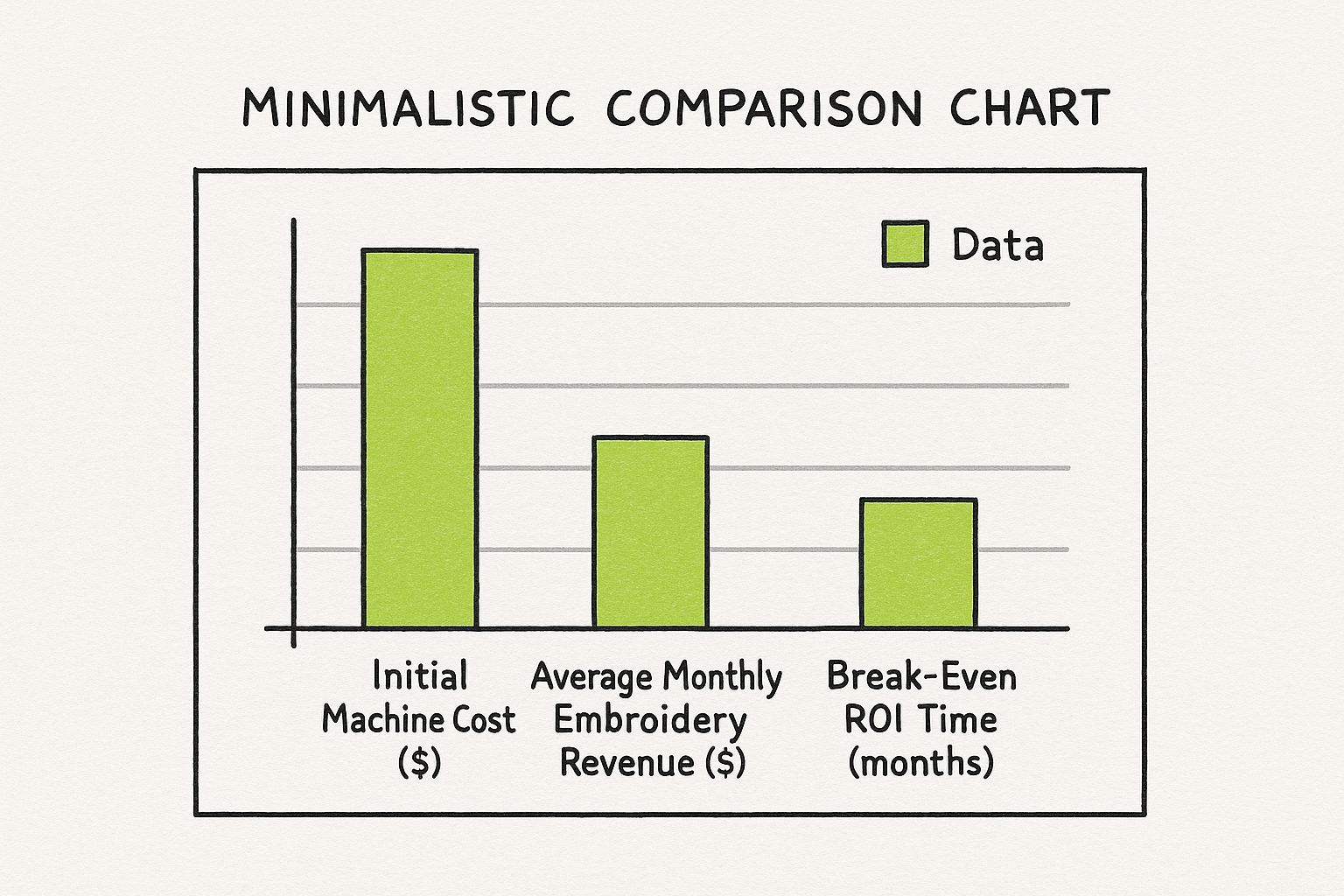

Take a look at this chart. It breaks down the financial side of things, from the initial price tag to potential revenue and how long it might take to get your money back.

As you can see, while the multi-needle machines have a steeper upfront cost, their ability to generate revenue faster often means a quicker return on investment, especially if you're focused on growth.

Comparing Single-Needle vs Multi-Needle Machines

To make it even clearer, let's put these two machine types head-to-head. This table breaks down the core differences to help you see which one aligns better with your business plan.

| Feature | Single-Needle Machine | Multi-Needle Machine |

|---|---|---|

| Best For | Hobbyists, Etsy shops, one-off custom jobs | Small businesses, bulk orders, high-volume production |

| Color Changes | Manual; you have to stop and re-thread for each color | Automatic; holds 4 to 16+ spools and switches on its own |

| Speed | Slower due to manual stops and starts | Much faster, designed for continuous operation |

| Hoop Size | Typically smaller, limiting design size | Larger embroidery fields for bigger designs |

| Item Versatility | Best for flat items like t-shirts and towels | Excellent for tricky items like caps, bags, and jackets |

| Cost | Lower initial investment | Higher upfront cost, but faster ROI with volume |

Ultimately, the right machine is the one that won’t hold your business back. A single-needle is a great entry point, but a multi-needle is what you'll need to truly scale up and tackle bigger, more profitable jobs.

It's About More Than Just Speed

The debate doesn't end with production speed. Multi-needle machines usually offer larger embroidery fields and come with specialized attachments that make it possible to work on items that are a nightmare to hoop on a standard machine, like caps, shoes, and tote bags. This versatility alone can open up entirely new product lines and customer bases for your business.

And if you're a multi-talented crafter, some machines can pull double duty. You can even find a great embroidery machine for quilting if you want to expand your creative services. Here at bsewinn.com, we don't just sell you a machine; we provide the training and resources you need to master it, so you can start turning its capabilities into profit from day one.

Key Features That Boost Your Bottom Line

When you're shopping for your first business embroidery machine, it’s so easy to get fixated on the price tag. I get it. But trust me, the features that really matter are the ones that make you faster, improve your quality, and ultimately, put more money in your pocket.

Think of these features less like expenses and more like investments. Each one is designed to save you precious time and open up whole new ways to make money.

Certain specs have a direct impact on what you can offer. Take hoop size, for example. A bigger hoop isn't just about making larger designs; it’s your golden ticket to working on high-value items like jacket backs, blankets, and oversized tote bags. These are the kinds of projects that command higher prices and attract a wider range of customers.

Embroidery speed is another big one. Measured in stitches per minute (SPM), a faster machine is a game-changer for any growing business. It means you can knock out orders quicker, which lets you take on more work, say "yes" to those rush jobs, and boost your output without chaining yourself to the machine.

Smart Technology That Saves Time

Modern machines are packed with tech that cuts down on manual work and saves you from those soul-crushing (and costly) mistakes. For a small business owner juggling a million tasks, these "quality of life" features are absolute lifesavers.

- Automatic Thread Tensioning: This is a huge one. The machine adjusts tension for you, giving you consistently clean stitches without you having to fiddle with dials all day. No more frustrating loops or puckered fabric.

- Automatic Thread Trimming: A machine that snips the threads between color changes or jump stitches will save you hours of tedious trimming. On a big order, this feature alone is worth its weight in gold.

- Wi-Fi Connectivity: Being able to send designs from your computer to your machine without plugging anything in is just plain smart. You can manage your entire workflow from your desk, keeping production humming along smoothly.

These kinds of advancements are a big reason the market for sewing and embroidery machines has ballooned to over $6.1 billion. People want customized stuff, and that demand is pushing manufacturers to make machines more powerful and easier to use than ever. If you're curious, you can explore more about this growing market and its trends.

The Bsewinn Advantage: Maximizing Your Machine

Here’s the thing: investing in a machine with all the bells and whistles is only half the battle. To really get your money's worth, you need to know how to use every single feature to its full potential. That’s where partnering with bsewinn.com becomes so valuable.

The best features in the world won't boost your bottom line if you don't know how to use them. Our goal is to bridge that gap with practical education and ongoing support, turning machine specs into real business growth.

Through our online classes and training resources, we walk you through everything your machine can do. We’ll show you how to master that automatic tensioning for perfect stitches on tricky fabrics and give you real-world examples of how to use larger hoops to create impressive, high-profit items. We’re here to help you unlock your machine’s full power so your investment pays for itself over and over again.

Budgeting for Your Embroidery Machine Investment

Let’s be real: a commercial embroidery machine is a serious purchase. But a smart business owner knows that the budget doesn't stop at the price tag on the machine itself. To get the full picture, you have to think in terms of total cost of ownership. This means factoring in the machine and all the supplies you'll need to hit the ground running and produce amazing work from day one.

Getting this figured out upfront saves you from those "oh no" moments when you realize you're missing a critical piece of the puzzle. A realistic budget means you can start making money right away, without any surprise expenses throwing a wrench in your plans.

Accounting for Startup Supplies

Think of your machine as the engine of your business—it’s powerful, but it can’t go anywhere without fuel. Budgeting for these initial supplies is one of the most important steps for any new embroidery machine for small business owner. You'll thank yourself later.

Here are the absolute must-haves:

- High-Quality Threads: Don't skimp here. You'll want a good starter set with a variety of colors. Investing in good thread from the get-go prevents the headaches of fraying and breaking, which saves you a ton of time and frustration.

- Stabilizers: Different fabrics need different support. You’ll need a few types—like cut-away, tear-away, and wash-away—to be ready for anything, from sturdy cotton polos to delicate knits.

- Specialized Hoops: Your machine will come with a set of standard hoops, but specialized ones for things like hats or tiny shirt pockets are what really open up your product offerings.

- Digitizing Software: This is the magic wand that turns digital images into stitch files your machine can actually read. Some machines include basic software, but a dedicated program is a game-changer for long-term growth and creativity.

The hunger for custom embroidered gear is booming, and the numbers back it up. The industrial embroidery machine market is projected to jump from $1.34 billion to $2.34 billion, which shows just how much opportunity is out there.

Calculating Your Return on Investment

Staring at a big price tag can feel intimidating. The best way to shrink that feeling is to map out your path to profitability. Let's run a quick return on investment (ROI) calculation to see how quickly your machine can start paying for itself.

Let's say you're selling custom embroidered polo shirts. A blank shirt costs you $10, and your supplies (thread, stabilizer, etc.) come out to about $1 per shirt. Your total cost is $11. If you sell that finished shirt for $30, you’ve just made a $19 profit.

By pricing out a few common items like custom hats and polo shirts, you can quickly visualize a clear path to profitability. This simple exercise transforms a large purchase into a manageable business investment with a tangible payback period.

A multi-needle workhorse like the Baby Lock Venture 10-Needle can churn out these items fast, letting you take on more orders and see that return on investment even quicker.

This is also where the support you get from bsewinn.com becomes such a crucial part of your investment. Our online classes and training resources help you sidestep those costly rookie mistakes with materials and designs. We want to see you creating professional, sellable products from the very beginning, which shortens your journey from investment to profit.

Setting Up Your Workspace for Success

Bringing your new embroidery machine home is a huge moment, but the real work—and fun—begins with the setup. This is where your business starts to feel real. Creating an organized, efficient workspace isn't just about being tidy; it's about building a professional production zone that cuts down on mistakes and lets your creativity flow.

Think of it this way: a well-planned space is your first business win before you've even threaded a needle. The absolute foundation of any good embroidery station is a sturdy, vibration-resistant table. An embroidery machine, especially a commercial-grade one, really gets moving. Pop it on a flimsy desk, and you're asking for skipped stitches, broken needles, and wonky designs. A solid surface is non-negotiable.

Getting Your Essential Tools in Order

Once your machine has a solid place to live, it's time to get your supplies organized for a smooth workflow. Trust me, nothing kills your momentum faster than digging through a drawer for the right thread color or stabilizer when you're on a deadline. A little organization upfront will save you so much headache later.

- Thread Storage: Wall-mounted racks or clear plastic bins are your best friends. They keep your colors visible and easy to grab, and they protect your thread from getting dusty and tangled.

- Stabilizer System: I like to store my stabilizer rolls on a simple dowel rod, but labeled drawers work great too. The key is keeping them flat and clearly marked so you don't accidentally grab a tear-away when you needed a cut-away. (We've all been there.)

- Tool Accessibility: Keep your small-but-mighty tools—scissors, tweezers, extra needles—within arm's reach. A magnetic strip on the wall or a simple pegboard does the trick perfectly.

The whole point is to create a setup where everything has a home. When you can move seamlessly from hooping a shirt to running the machine, your workspace stops being just a table and becomes an actual production line.

Your First Project: Time to Make Something!

Okay, now for the exciting part: bringing that machine to life. The initial power-up involves installing any software and running a few test stitches to make sure everything is humming along perfectly. From there, the best way to learn is by doing.

This is where the support from bsewinn.com becomes invaluable. Our online tutorials are designed to walk you through everything, step-by-step, turning what could be an intimidating process into an exciting first project. A great place to start is with a simple monogrammed tote bag. It's low-risk but gives you a high-reward feeling, and it's perfect for getting the hang of hooping, design placement, and thread tension.

By making something you can actually hold right away, you build confidence from day one. This hands-on approach, combined with all our resources, ensures your journey with your new embroidery machine for small business kicks off with a finished product you can be proud of, not a headache.

Keeping Your Machine Humming

Think of your embroidery machine as the engine of your business. Just like you wouldn't drive a car for months without an oil change and expect it to run well, your machine needs a little consistent TLC to keep churning out perfect stitches. A little proactive care goes a long way in preventing those dreaded, costly downtimes that can throw your whole production schedule off track.

Honestly, a simple daily habit can head off most of the common headaches. Before you start stitching for the day and after you're done, just take a minute to dust off the machine. Pay special attention to the bobbin case and along the thread path—that's where lint loves to party. This tiny step is your first line of defense for clean stitches and a happy machine.

Your Go-To Maintenance Checklist

Beyond a quick daily dusting, having a real maintenance schedule is the secret sauce. When you stick to a routine, your embroidery machine for small business becomes that reliable workhorse you can count on, no matter what order comes in. We're not talking about complicated, tear-it-apart repairs here, just simple preventative stuff.

Here are the big three to build into your workflow:

- Swap Those Needles: Don't wait for a needle to snap mid-job. A dull or slightly bent needle is the number one culprit behind shredded thread and snagged fabric. The rule of thumb I always follow is to pop in a new needle after every 8-10 hours of actual embroidery time.

- Oil It Up: Every machine is a little different, so pull out that manual and see where and when it needs to be oiled. Proper lubrication is what keeps all those moving parts from grinding against each other. It prevents premature wear and tear and keeps things running quietly and smoothly.

- Clean the Bobbin Case: Lint and tiny thread bits are notorious for building up in the bobbin area. A quick sweep with a soft brush at the start of each day is all it takes to prevent tension nightmares and that awful "bird's nesting" on the back of your projects.

You'll eventually develop an ear for your machine. Recognizing the early warning signs—a new rattle, a funny noise, or stitches that just look off—is a skill in itself. Catching these little things right away can stop them from snowballing into major, order-stopping disasters.

This is where having a partner you can trust really makes a difference. At bsewinn.com, we don't just sell you a machine and wish you luck. We want you to feel confident handling all the routine care yourself. Through our huge resource library and online training classes, you'll learn not just how to run your machine, but how to properly care for it. We're here to give you the support you need for basic troubleshooting, so you can protect your investment for years to come.

Got Questions? We've Got Answers

Stepping into the world of embroidery entrepreneurship is a huge thrill, but it usually comes with a mountain of questions. Getting straight, practical answers from day one can make all the difference and help you build your new business on solid ground. Let's tackle some of the most common questions we hear from folks just starting out.

One of the first things everyone asks about is the machine itself. Can you really start a business with one of those more affordable single-needle machines?

Can I Really Start a Business With a Single-Needle Machine?

You absolutely can. A single-needle machine is a fantastic, accessible way to get your foot in the door. I've seen countless successful Etsy shops and custom gift businesses get their start with a quality single-needle model.

Sure, you have to manually change the thread for each color, but it’s the perfect way to learn the craft and build a portfolio of beautiful work without a huge upfront investment. They're ideal for mastering monogramming and unique, one-off orders that build a strong brand.

Once your orders start piling up and your designs get more complex, you can then make a strategic jump to a multi-needle embroidery machine for small business. That’s when you’ll really see your production speed take off.

What Software Do I Need Right Away?

Your new machine will likely come with some basic software for arranging and editing designs you already have. Honestly, that’s more than enough to get your first projects stitched out. My advice? Focus on mastering those built-in tools first.

Down the road, when you're ready to create completely original designs from scratch, you'll want to invest in dedicated digitizing software.

The online resources at bsewinn.com can walk you through the fundamentals of design placement and editing. You'll have a much better feel for when investing in more advanced software is the right next step for your business.

How Do I Price My Embroidery Work to Actually Make a Profit?

This is the million-dollar question! A common starting point in the industry is to charge per 1,000 stitches—often somewhere between $1.00 and $1.50. On top of that, you'd add a one-time setup fee for digitizing a new design.

This method helps cover your time, thread, stabilizer, and the wear-and-tear on your machine. And don't forget the most important part: always factor in the cost of the garment itself!

Beyond the machine, it's smart to get a handle on the business side of things. Simple things like avoiding common accounting mistakes from the get-go can save you a world of headaches later. Take a look at what others in your area are charging, but price your work with confidence. You're selling your unique quality and creativity, so don't undervalue it.

At bsewinn.com, we don’t just sell machines; we provide the entire support system to help you succeed. From online classes that show you how to create beautiful designs to a huge library of resources, we’re here to empower your creative journey. Explore our full range of machines and educational offerings at https://www.bsewinn.com.