There’s nothing quite like the feeling of being in a creative groove, only to have your sewing machine grind to a halt. It’s a momentum killer, and the immediate instinct is to find someone—anyone—who can fix it now. But jumping on the first "sewing machine repair in my area" result can cause more headaches than it solves.

A shoddy, quick fix can be disastrous. Think poor stitch quality that ruins your project, damaged fabric from a misaligned feed dog, or even permanent harm to your machine’s delicate internal parts. This guide is designed to empower you with the knowledge to find the right help and maintain your machine, ensuring your creative journey is seamless.

Why Finding The Right Local Repair Shop Is Crucial

When your machine is down, the goal is just to get it running again. But the quality of that repair makes all the difference. Choosing an unskilled technician can easily turn a simple timing adjustment into a major expense.

Imagine getting your machine back, only to find the tension is still completely off, shredding that beautiful silk you’ve been saving. Or worse, the computerized board on your prized machine gets fried because the person working on it wasn't familiar with its electronics. These things happen when you don’t take a moment to vet your repair service.

The Rise of Home Sewing and Repair Needs

The world of sewing has absolutely exploded. With a renewed passion for DIY projects and sustainable fashion, more people are bringing machines into their homes than ever before. The global sewing machine market hit around $7.1 billion recently and is on track to reach $10.5 billion by 2033. You can read more about the growing sewing machine market and its trends.

This sewing boom means more people need reliable repair services. Unfortunately, not every shop has the deep expertise needed to keep up with the demand and the technology in modern machines.

Taking a little extra time to find a skilled, trustworthy technician is the single most important thing you can do. It will save you time, money, and frustration, ensuring your beloved machine is in truly capable hands.

Here at bsewinn.com, we believe a well-cared-for machine is the key to creative freedom. Our commitment goes beyond providing unique custom sewing machine designs; we aim to empower crafters. Through our comprehensive online classes and resources, we provide the support you need to understand your machine inside and out, from basic maintenance to creating stunning projects.

This understanding helps you figure out when a simple tweak is all that's needed, versus when it's really time to call in a professional. Finding a true expert protects your investment and makes sure every project you dream up turns out just right.

How To Uncover The Best Local Repair Options

Finding the right person to trust with your sewing machine takes more than a quick Google search for "sewing machine repairs in my area." The best approach is a mix of smart searching and old-fashioned word-of-mouth. This way, you move past anonymous online listings and find the technicians your local sewing community actually relies on.

First, get specific with your online searches. Instead of a vague query, try something like “vintage Singer repair near me” or “authorized Brother service center [your town].” Being specific helps weed out the generalists and connects you with specialists who genuinely know the ins and outs of your machine.

Tap Into Your Local Sewing Community

I can't stress this enough: the absolute best referrals come from fellow sewists. Your local community is a goldmine of honest, firsthand experience that you just can't find anywhere else. These are people who, just like you, depend on their machines and have already done the hard work of vetting local services.

Here's where to start digging:

- Local Fabric Stores: The staff at independent fabric and quilt shops are the unofficial hub of the local sewing scene. They hear it all—the good, the bad, and the ugly—about area technicians and can usually point you toward the most trusted pros.

- Online Sewing Forums and Social Media Groups: Jump into a local or state-specific sewing group on Facebook or a dedicated platform like PatternReview.com. Post a question asking for recommendations. You'll be amazed at the detailed, personal stories people are willing to share.

- Sewing Guilds and Classes: If you’re part of a quilting guild or have taken a local class, your instructor and classmates are your best friends here. Ask them who they trust with their machines when things go wrong.

A little organization goes a long way. As you gather names, jot down their contact info, what brands they specialize in, and who recommended them. This simple list will make comparing your options so much easier when it's time to decide.

Here at bsewinn.com, we are committed to empowering you in every aspect of your craft. While our custom designs and extensive resources are here to build your skills, we know that sometimes you need a professional's touch. For more on this, check out our guide on who repairs sewing machines. Knowing your options ensures your machine gets the best possible care.

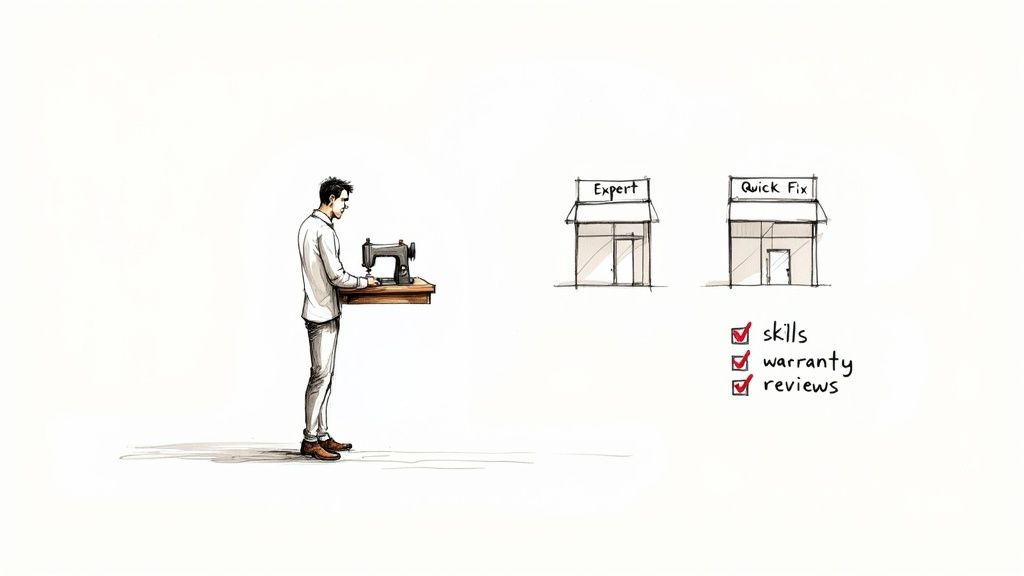

Choosing The Right Tech For Your Machine Type

Not all sewing machines are the same, and neither are the people who fix them. That delicate vintage Singer your grandma passed down needs a completely different kind of expert than a shiny, new computerized embroidery machine. This is why you need to find a tech whose skills match your specific machine.

First, confirm they have hands-on experience with your brand and model. Don't be shy about asking direct questions when you call. Something like, "How often do you work on Brother embroidery machines?" or "Are you comfortable servicing older, all-metal Kenmore models from the 70s?" Their answer will tell you everything you need to know.

If you're new to the sewing world and aren't even sure what kind of machine you have, this guide to choosing a sewing machine is a great place to start understanding the different types out there.

This infographic breaks down a simple way to approach your search for a local repair pro.

As you can see, the best strategy is a mix of everything: hitting up Google, asking your sewing circle for recommendations, and checking in with your local fabric or quilt shops.

Matching Skills to Machine Technology

This has become even more important as sewing machines have gotten more complex. Today's computerized models are incredible, but they require a tech who is part mechanic, part IT specialist.

For any modern, computerized machine, you absolutely have to ask if the shop is an authorized service center for your brand. This isn't just a fancy title. It means they've been trained by the manufacturer and can get their hands on genuine parts and special diagnostic tools. Our guide on Brother sewing machine repairs near me dives deeper into why this is such a big deal.

A technician who primarily services vintage mechanical machines might be completely lost with a computerized model's motherboard. Asking about their comfort level with electronic components and diagnostic software isn't being difficult—it's being smart and protecting your investment.

To make sure you're covering all your bases, here's a quick checklist of questions to run through with any potential technician.

Key Questions To Ask A Potential Repair Technician

Use this checklist to vet any repair service and ensure they have the expertise to handle your specific sewing machine.

| Question Category | Specific Question to Ask | What a Good Answer Looks Like |

|---|---|---|

| Experience | "What brands and types of machines do you specialize in?" | "We work on most modern brands like Brother and Janome, and I have a lot of experience with vintage Singers, too." |

| Authorization | "Are you an authorized dealer or service center for my machine's brand?" | "Yes, we're an authorized service center for Bernina, which means we get factory training and use official parts." |

| Parts | "Do you use genuine manufacturer parts or aftermarket ones?" | "We always use original manufacturer parts whenever possible to ensure the best performance and fit." |

| Diagnostics | "For computerized machines, do you have the software to run diagnostics?" | "Absolutely, we have the diagnostic tools for all the major computerized brands we service." |

| Timeline | "What's your typical turnaround time for a standard tune-up or a specific repair like mine?" | "For a tune-up, we're usually about a week out. For a repair, it depends, but I can give you an estimate after I see it." |

| Warranty | "Do you offer a warranty on your repair work?" | "Yes, all our repairs are covered by a 90-day warranty on both parts and labor." |

Getting clear answers to these questions will give you the confidence that you're leaving your machine in capable hands.

At the end of the day, the goal is to find a perfect match between your machine's needs and the tech's skills. It's the surest way to get a solid, lasting repair that lets you get back to creating without any more headaches.

Decoding Repair Costs And Timelines

Let's talk about the two things that can make or break a repair experience: surprise bills and a machine that seems to be gone forever. You’re itching to finish a project, and the last thing you want is an unexpected cost or a vague timeline.

Most shops have a couple of standard ways they handle pricing. A common one is a diagnostic fee right up front. This covers the technician's time to figure out exactly what’s wrong. The good news is that this fee is almost always rolled into the final repair bill if you give them the green light.

Another popular option is a flat-rate servicing package. This is your basic "clean, oil, and adjust" service and it’s perfect for routine maintenance. Just keep in mind that if they find a part that needs replacing, that’s usually an extra charge on top of the flat rate.

Getting A Clear And Actionable Estimate

To avoid any headaches, always ask for a detailed estimate in writing before you agree to any work. A trustworthy shop will have no problem breaking down the costs for you, separating labor from parts. That transparency is a huge green flag.

If you want a deeper look at what to expect price-wise, we put together a detailed guide on the cost of sewing machine repair that breaks it all down.

Several things can affect how much you'll pay and how long you'll be without your creative partner:

- Machine Complexity: Fancy computerized or embroidery machines often require specialized diagnostic tools, which can bump up the service cost.

- Parts Availability: Got a gorgeous vintage machine? Tracking down a specific part can be a bit of a treasure hunt, which can add to the timeline and the final bill.

- Shop Backlog: A busy shop is usually a good sign, but it can also mean a longer wait. It never hurts to ask about their current turnaround time when you drop your machine off.

When you're comparing quotes, try to look beyond just the final number. A slightly higher price from a technician with years of experience who guarantees their work with a warranty is often a much better investment than the cheapest option. Peace of mind is priceless.

From Repair to Creation: Empowering Your Sewing Journey

Finding a great repair tech is a huge win. But the real goal is to keep your machine humming so you rarely need to google "sewing machine repairs in my area." This is where proactive care and knowledge become your secret weapon. This guide is your first step—from finding help to becoming a more confident crafter.

Here at bsewinn.com, we are passionate about empowering your entire creative process. We don't just provide custom sewing machine designs; we offer comprehensive support through online classes and training to help you master your craft and bring your visions to life.

How-To Guides for Your Next Project

Our resources serve as comprehensive "how-to" guides, showing you how to create tangible, beautiful projects. For example, our online classes can walk you through:

- Creating a Custom Quilted Tote Bag: This project teaches you precision piecing, free-motion quilting techniques, and how to install hardware for a professional finish.

- Embroidering a Monogrammed Towel Set: Learn to stabilize delicate fabrics, perfectly align your designs using your machine's software, and choose the right threads for a lush, lasting result.

- Sewing a Flawless Zipper Pouch: A tangible example that helps you master one of sewing's most-feared skills, turning it into a simple, repeatable process.

Knowing the difference between a quick, five-minute fix you can do yourself and a genuine mechanical issue that needs a pro will save you so much time, money, and creative momentum. Think of this knowledge as an investment in your craft.

For more great habits, you can find a ton of useful general sewing tips and tricks. Our mission at bsewinn.com is to arm you with the skills and support you need, so your machine stays a reliable partner for every single project you dream up.

Common Questions About Sewing Machine Repair

Figuring out sewing machine repairs can feel a little daunting. You just want to get back to your projects! I get these questions all the time, so let's clear up some of the most common ones right now.

How Much Should A Standard Sewing Machine Service Cost?

This is the big one, right? For a standard mechanical machine, a basic "clean, oil, and adjust" service will usually run you somewhere between $75 and $150.

If you've got a more complex computerized or embroidery machine, expect something in the $150 to $250 range, since there are electronic diagnostics and trickier adjustments involved. My best advice? Always ask for a detailed estimate before you give them the green light.

Is It Worth Repairing An Old Or Inexpensive Sewing Machine?

This is a classic "it depends" situation.

Is it a high-quality vintage mechanical machine? Those old metal workhorses? Almost always, yes. They were built like tanks and are absolutely worth keeping alive.

But if you're talking about a budget machine that you bought new for under $150, you have to do the math. If a repair is going to cost you over $100, it might not make sense unless it’s a super simple fix. It really comes down to weighing the repair estimate against what a brand-new machine would cost.

Pro Tip: When you drop off your machine, bring the essentials! That means the power cord, foot pedal, a standard presser foot, and the bobbin case. And the gold-star move? Bring a scrap of fabric that clearly shows the problem you're having. It helps the technician diagnose the issue so much faster.

How Often Should I Get My Sewing Machine Professionally Serviced?

If you're sewing a few times a week, getting a professional tune-up every 12-18 months is a great rule of thumb. It keeps everything running smoothly.

If you sew every single day or you're constantly working with fluffy, lint-heavy fabrics like fleece or minky, you should probably bump that up to a yearly service. This kind of proactive care helps you avoid much bigger, and more expensive, headaches later on.

At B-Sew Inn, we know that having the right information is just as important as having the right machine. We don’t just offer custom sewing machine designs; we're here to help you become a more confident sewist with our huge library of online classes, training, and extensive resources. We are committed to empowering crafters through dedicated support and education.

Explore Our Custom Sewing Machines and Educational Resources