We've all been there. You're in the zone, crafting a beautiful design, and then… silence. Or worse, a horrible grinding noise. Your project comes to a screeching halt, and that sinking feeling hits.

Before you jump to conclusions and start searching for repair shops, take a deep breath. Many of the most common sewing machine meltdowns are things you can absolutely fix yourself. It might be as simple as a tired needle or a thread that's gone rogue, saving you a trip and a repair bill. At bsewinn.com, we are committed to empowering crafters like you with the skills to handle these moments, supported by our custom sewing machine designs, online classes, and extensive resources.

Your First Steps When Your Machine Falters

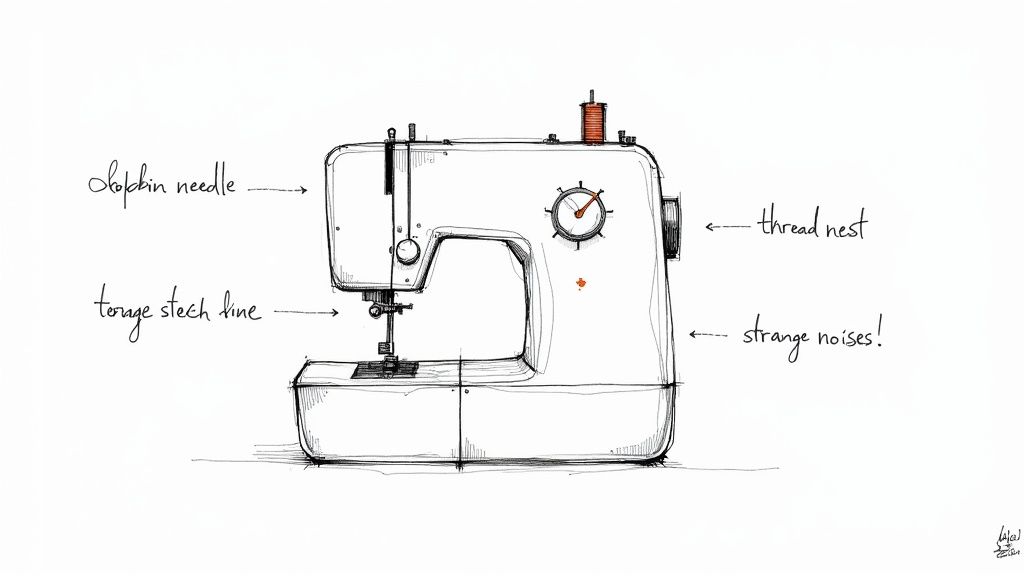

It’s easy to panic when you see that dreaded "bird's nest" of thread forming under your fabric or hear a clunk that just doesn't sound right. But trust me, running through a quick mental checklist can often solve the problem in minutes, not days. This is a skill every crafter should have—it helps you understand your machine and keeps your creativity flowing.

So, before you pack it up, ask yourself these questions:

- When did I last change the needle? Seriously. A dull, bent, or incorrect needle is the culprit behind over 70% of stitch problems. It's the first thing I check.

- Is it threaded correctly? Even seasoned pros miss a guide now and then. It's always worth unthreading completely and starting fresh.

- Is the bobbin area clean? Lint and dust bunnies love to party in there, and they can jam up the works faster than you'd think.

Here's a quick way to think about it before escalating to a professional repair.

As you can see, most paths lead back to simple things you can handle right at your sewing table.

To DIY or To Call a Pro? That Is the Question.

Knowing the difference between a minor hiccup and a major mechanical failure is key. Things like skipped stitches often point to a needle or tension issue that you can easily adjust. But if you hear grinding metal, smell something electrical (like burning plastic), or see that the timing is off (the needle is actually hitting the hook assembly), stop immediately. Those are clear signs it’s time to call in an expert.

To help you sort it out, here’s a quick diagnostic table you can run through.

Quick Diagnostic Checklist for Common Issues

Use this table to quickly identify your sewing machine problem and decide if it's a DIY fix or time to call a professional.

| Symptom | Likely Cause | Your DIY Action | When to Seek a Pro |

|---|---|---|---|

| Skipped Stitches | Dull/wrong needle, incorrect threading. | Change the needle, re-thread the machine. | If the problem persists after trying multiple needles. |

| "Bird's Nest" of Thread | Upper tension is too loose, incorrect threading. | Re-thread the machine, checking all tension discs. | If tension assembly seems broken or unresponsive. |

| Loud, Clunking Noise | Lint buildup in bobbin case, needle hitting something. | Clean the bobbin area, check needle for bends. | If the noise is a metallic grinding sound. |

| Machine Won't Turn On | Power cord isn't fully plugged in, foot pedal connection is loose. | Check all connections at the wall and machine. | If you smell burning or the motor is dead silent. |

This isn't an exhaustive list, but it covers the most frequent issues that pop up during a project.

At bsewinn.com, we're all about empowering you. While a good technician is worth their weight in gold for serious problems, our goal is to give you the confidence and know-how to handle the everyday stuff on your own through our training and resources.

For a deeper look into these issues and how to solve them, check out our detailed sewing machine troubleshooting guide. Mastering these basic checks will save you time and money, and you'll build a much better connection with your most important creative partner.

Finding and Vetting Local Repair Technicians

Alright, you've done the basic troubleshooting, and it's clear the problem is more than just a quick DIY fix. Now begins the real hunt for someone who knows their way around the inside of a sewing machine. This isn't just about finding the closest shop; it's about finding an expert you can trust with your creative partner. A good tech can be a lifelong ally, keeping your machine humming for years.

So, where do you even start? Your first port of call should be asking other crafters. Some of the best recommendations come from word-of-mouth. Chat with the folks at your local fabric store or members of your quilting guild. They’ve likely been using the same independent technicians for ages and can give you the real scoop on who to trust and who to avoid.

If your machine is a specialized brand, seeking out an authorized service center is a smart move. Their technicians receive factory-level training on those specific models, ensuring they have the precise knowledge needed for your machine.

Key Questions for Any Technician

Before you hand over your machine, you need to play detective for a few minutes. A true professional will have no problem answering these questions. In fact, they should welcome them.

- Have you worked on my specific brand and model before? Experience matters. The skills needed for a vintage, all-metal machine are worlds away from what's required for a modern, computerized embroidery model.

- What’s your current turnaround time? This is crucial for planning your projects. There's nothing worse than having a deadline and finding out your machine will be in the shop for weeks.

- Do you provide a written estimate before you start the work? This is a non-negotiable. You should never, ever be surprised by the final bill. Get it in writing.

- Do you offer a warranty on your repairs? Any reputable shop will stand by their work. Look for a warranty of at least 30 to 90 days on the service they perform.

Finding the right person to repair your sewing machine is a critical part of the craft. A skilled technician not only fixes the immediate problem but also spots potential issues, saving you future headaches and downtime.

The need for these skilled professionals is only growing. The sewing machine market in North America is massive—the United States alone is projected to hit a market size of around USD 1.99 billion by 2025. All those machines rely on a network of manufacturer service centers, local repair shops, and talented independent techs to keep them stitching.

At the end of the day, this search is about finding someone with both expertise and integrity. For a more focused list of options, you can also check out our guide on finding sewing machine repairs near you.

Why Skilled Sewing Machine Technicians Are So Hard to Find

Ever feel like finding a great sewing machine mechanic is like searching for a needle in a haystack? You're definitely not alone. When you start asking around for who repairs sewing machines, you quickly run into a surprising truth: there's a real shortage of skilled people in this field.

This isn't just about finding someone who can tighten a few screws. Your sewing machine isn't the simple, all-metal workhorse your grandmother used. Today's machines are marvels of engineering, mixing old-school mechanical know-how with seriously advanced digital tech.

The Modern Machine's Complexity

Take a look at any modern computerized sewing or embroidery machine, and you'll see it's packed with high-tech parts. It's a whole different world inside that casing.

- Circuit boards are the brains of the operation, telling your machine which stitch to make and when.

- LCD touchscreens have replaced clunky dials, giving you a full-on digital interface.

- Tiny sensors are constantly at work, monitoring everything from thread tension to the exact position of your needle.

This jump in technology means a good technician needs a very specific, and rare, combination of skills. They have to be a classic mechanic who understands gears, timing, and tension, but also a tech wizard who can diagnose a faulty sensor or a buggy circuit board. Finding someone who's an expert in both is getting tougher every year.

The big shift from purely mechanical machines to electro-mechanical ones has created a huge skills gap. The generation of technicians who were masters of the vintage, all-metal machines are retiring. And frankly, not enough new people are coming into the trade with the right training to handle today's complex, computerized models.

The Widening Skills Gap

This isn't just a sewing problem; it's part of a worldwide shortage in skilled trades. Industrial sewing machines have gotten even more complex, often using things like programmable logic controllers (PLCs) and intricate sensor arrays. This requires technicians to be experts in mechanics and electronics, creating a bottleneck for repair shops trying to find qualified staff. You can discover more about the challenges in the sewing machine market right here.

This reality check makes preventative maintenance more important than ever. Here at bsewinn.com, we’re all about empowering you to handle things yourself. With our deep well of resources, online classes, and specific training for our custom machines, we want to give you the confidence to tackle common issues. This not only extends the life of your machine but also makes you less reliant on those hard-to-find pros.

How to Get Your Machine Ready for Service

There's nothing more frustrating than lugging your machine to a repair shop, only to realize you left a crucial part at home. Walking in and just saying "it's making a weird noise" is a recipe for a longer, more expensive visit.

A little prep work goes a long way. Think of it like going to the doctor—giving them a clear list of symptoms leads to a much faster and more accurate diagnosis. The same is true for your sewing machine technician.

What to Bring to the Repair Shop

Before you even head out the door, gather a small "go-kit" for your machine. Forgetting a key part is a super common mistake, but it can cause serious delays. The goal is to give the technician everything they need to replicate the exact problem you're having.

Here’s what you absolutely must bring:

- The Power Cord and Foot Pedal: These are non-negotiable. The tech can't even turn the machine on without them, let alone test its functions.

- The Bobbin and Bobbin Case: Even if you're sure the issue is with the needle or the thread, the bobbin is a critical piece of the stitch-forming puzzle. Always bring them.

- The Presser Foot You Were Using: If the trouble started when you were using a specific foot, like your zipper foot or that fancy buttonhole attachment, bring that exact one.

- A Fabric Swatch Showing the Problem: This is your golden ticket. A small piece of fabric showing the skipped stitches, thread nests, or tension issues is the best evidence you can provide.

I can't stress this enough: the single most helpful thing you can do is document the problem. A simple sticky note explaining what’s happening, what kind of fabric and thread you were using, and what you’ve already tried to fix it can cut the diagnostic time in half.

This little bit of prep isn't just to make the technician's job easier—it helps you get an accurate and efficient repair. When you set them up for success, they can solve the right problem the first time, getting your beloved machine back into your creative hands that much sooner.

Empower Yourself with DIY Maintenance Skills

Before you start hunting for a repair tech, it’s worth remembering that a surprising number of sewing machine frustrations can be solved right in your sewing room. Honestly, most "big" problems aren't big at all.

Building up a little bit of basic maintenance knowledge doesn't just save you a trip to the shop; it fundamentally changes your relationship with your machine. You go from just using it to truly understanding it, which makes you a much more confident and intuitive crafter. Most performance hiccups don't come from some catastrophic mechanical failure—they're usually just the machine's way of telling you it needs a little TLC.

Lint and dust are public enemy number one for a sewing machine. They build up, create friction, and soak up the oil that keeps everything running smoothly. Regular cleaning is the single most important skill you can learn.

Mastering the Essentials

Knowing how to handle a few key tasks will solve the vast majority of your everyday sewing headaches. Think of these as the foundation for a healthy machine and happy, frustration-free crafting.

Here are the core skills that every crafter should have in their back pocket:

- Proper Cleaning and Oiling: Get comfortable removing the needle plate and bobbin case to clear out all that sneaky lint buildup. A tiny brush and a bit of canned air can work wonders. Afterward, a single drop of high-quality sewing machine oil in the right spots keeps everything moving like a dream.

- Changing Needles Correctly: This is a big one. A dull, bent, or damaged needle is the number one cause of skipped stitches, shredded thread, and damaged fabric. Make it a habit to change your needle after every 8-10 hours of sewing. And always make sure the flat side of the shank faces the back of the machine!

- Adjusting Thread Tension: Learning to "read" your stitches is a game-changer. Understanding the delicate balance between the upper thread and the bobbin thread—and knowing how to make small tweaks to your tension dial—will fix so many common stitch quality issues.

Mastering these basic maintenance tasks is the first step toward creative freedom. When you understand how your machine works, you're better equipped to push its creative boundaries without fear.

Here at bsewinn.com, we're all about empowering you on this journey. We’ve put together a huge collection of online resources, including detailed classes and training videos made specifically for our custom machine designs. Our goal is to give you the skills you need so you can spend less time troubleshooting and more time creating beautiful, tangible designs that you can replicate and be proud of.

Your Questions About Sewing Machine Repair Answered

When your beloved sewing machine starts acting up, a flood of questions usually follows. I get it. Trying to figure out the world of maintenance can feel a little daunting, but knowing the ropes helps you make smart decisions for your most important creative tool. Let’s clear up some of the most common questions we hear from fellow crafters.

How Often Should My Sewing Machine Be Serviced?

This is a big one. As a general rule of thumb, plan for a professional service every 12 to 18 months. The exact timing really depends on how much you sew.

If you’re at your machine nearly every day, an annual tune-up is a fantastic investment. It keeps everything running in peak condition. For those of us who are more occasional hobbyists, stretching that to every two years is probably fine.

A professional service is so much more than the cleaning we do at home. A technician will do a deep clean of all those hard-to-reach spots, apply the right lubrication, check crucial timing adjustments, and balance the tension. It’s the kind of expert care that makes your machine run like new and, more importantly, catches tiny issues before they turn into major headaches.

Is It Worth Repairing an Older Sewing Machine?

Oh, this is a question close to my heart! It really boils down to the machine’s original quality and its sentimental value. Those wonderful vintage, all-metal machines? They are almost always worth fixing. They were truly built to last for generations, and their rock-solid construction makes them perfect candidates for restoration.

For a modern, entry-level plastic model, the decision is more about the numbers. Always, always get a detailed estimate before you agree to any work. If the repair bill is getting close to what it would cost to just buy a new one, it might be more practical to invest in a new machine. For a deeper dive into the numbers, our guide on the cost of sewing machine repair is a great resource.

Your choice between an authorized dealer and an independent shop often comes down to your machine's warranty status and age. Both can provide excellent service, so it's about finding the right fit for your specific needs.

An authorized dealer is certified by a specific brand to sell and service their machines. They're your go-to for in-warranty work because they use official parts and have brand-specific training. On the other hand, independent shops are amazing resources. They often work on a wider variety of brands and ages—including those cherished vintage models—and can sometimes offer more competitive pricing.

Here at bsewinn.com, our whole goal is to empower you with the knowledge and the tools you need for your craft. Whether you're trying to keep a vintage treasure stitching or maintaining a modern workhorse, our resources, online classes, and custom machine designs are here for you. Take a look through our collection and find everything you need to keep your creative journey moving forward with confidence.