Before you even start searching for “sewing machine repairs near me,” it's wise to determine if you're dealing with a simple user error or a genuine mechanical problem. At bsewinn.com, we believe in empowering crafters, and that starts with understanding your machine. Knowing the difference can save you time, frustration, and an unnecessary trip to the shop, freeing you up to focus on creating beautiful sewing machine designs.

Recognizing the Signs Your Sewing Machine Needs a Pro

We've all been there. You're in the middle of a project, inspired to create, and then your machine throws a fit. Sometimes, it’s an easy fix like re-threading or popping in a new needle. But other times, your machine is waving some serious red flags that it needs an expert.

Ignoring these signals can turn a small issue into a much bigger, more expensive headache. For instance, if you hear a loud, rhythmic ‘clunking’ sound, especially when you’re powering through something heavy like denim, that often points to a timing issue. That’s not something a simple tune-up can solve. A persistent grinding noise is an even bigger deal—it’s a major warning that internal gears or parts are really struggling.

Common Symptoms of a Deeper Problem

Beyond just weird noises, pay close attention to how your machine is behaving. Do any of these frustrations sound familiar?

- Inconsistent Stitches: Your tension was perfect yesterday, but today your stitches are all over the place—uneven, skipping, or looping. This could mean the tension assembly itself has a problem.

- Constant "Bird's Nests": A little bit of thread nesting under your fabric happens to the best of us. But if it’s happening constantly and you can't figure out why, you could be looking at an issue with the bobbin case, timing, or hook assembly.

- A Hot or Burning Smell: If you notice a hot, almost burning smell from the motor after just a short seam, that's a serious warning. Unplug your machine right away and get it looked at by a professional.

It's so easy to blame yourself when things go haywire, but a well-maintained machine shouldn't be fighting you on every single seam. Trust your gut—if something just feels or sounds fundamentally wrong, it probably is.

Many of these problems are tricky to diagnose on your own. For a more detailed breakdown of what you can likely fix at home versus what really needs an expert eye, check out our comprehensive sewing machine troubleshooting guide. It’s a great resource to look at before you book that service appointment.

How to Find and Vet the Best Local Repair Shops

So, you've decided your machine needs a pro's touch. Now the real fun begins: finding a reliable technician you can trust. A quick "sewing machine repairs near me" search is a start, but the best finds often come from word-of-mouth.

Your first stop should be your local sewing community. Tap into local sewing guilds or check out crafting groups on Facebook. These folks are usually more than happy to share their honest, firsthand experiences—both good and bad!

Don’t forget about your favorite fabric shop, either. The staff there are a goldmine of information. They hear it all from their customers and can often point you toward the most reputable shops in town. For those of you with specific brands like a Bernina or Janome, brand-specific online forums can be a lifesaver for finding a tech who really knows the ins and outs of your particular model.

Vetting Your Potential Repair Tech

Finding a shop is one thing, but making sure they’re the right shop is what really matters. A good technician can be the difference between a quick, lasting fix and a recurring nightmare that costs you more time and money. Before you hand over your beloved machine, it's smart to ask a few key questions to get a feel for their expertise and how they do business.

When you're checking out a potential repair shop, pay attention to their customer service. A shop that communicates clearly and professionally is usually a good sign of their overall quality.

Here are a few essential questions I always ask:

- Do you have experience with my specific brand and model? (This is crucial for computerized machines!)

- What’s your average turnaround time for a standard service?

- Do you offer a warranty on your repair work? If so, what does it cover and for how long?

- Can you give me a ballpark estimate before I bring my machine in?

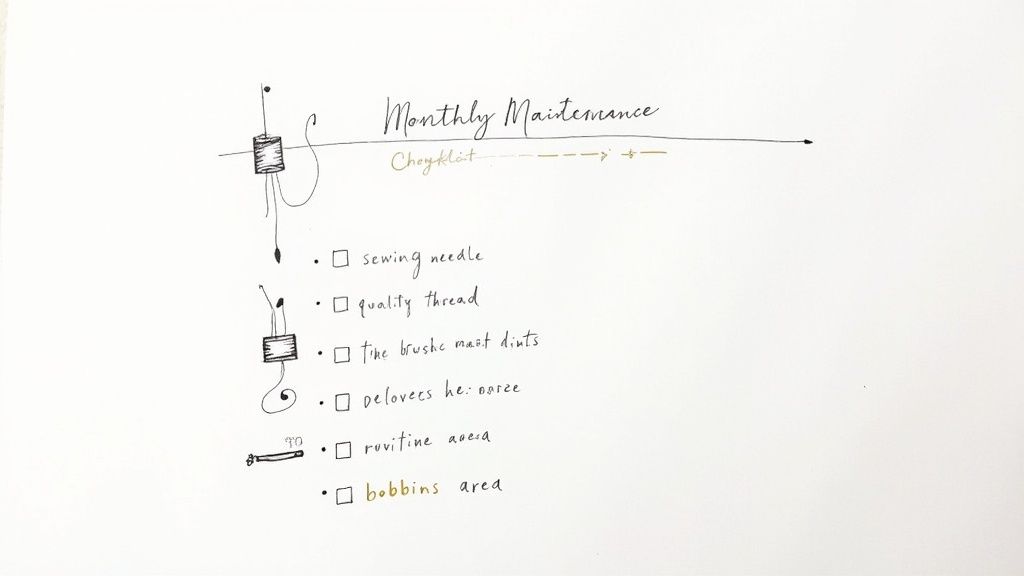

This visual guide is also a great little cheat sheet for deciding whether to DIY or call in a professional.

As the infographic shows, while we can handle many common hiccups ourselves, things like weird mechanical noises or electrical issues are definite signals to step away and call a pro.

A reputable shop will always be transparent about its process and pricing. If you get vague answers, a flat-out refusal to provide an estimate, or see a string of negative recent reviews, trust your gut. Those are major red flags.

Comparing Local Sewing Repair Options

To help you decide, here’s a quick-glance comparison of the most common types of repair services you’ll find. Each has its pros and cons, so think about what’s most important for you and your machine.

| Factor | Authorized Dealer | Independent Repair Shop | Hobbyist Technician |

|---|---|---|---|

| Expertise | Brand-specific, factory-trained specialists. | Broad experience across various brands and models. | Often self-taught with variable skill levels. |

| Parts | Uses genuine manufacturer parts. | May use genuine or third-party parts. | Access to parts can be limited. |

| Warranty | Repair work is usually warrantied. | Warranty policies vary widely. | Unlikely to offer a formal warranty. |

| Cost | Typically the highest cost. | Moderate and often more competitive pricing. | Usually the most affordable option. |

| Turnaround | Can be longer due to high volume. | Often faster, with more personalized service. | Highly variable; depends on their schedule. |

Ultimately, an authorized dealer is your safest bet for a machine still under warranty, while a trusted independent shop can be a fantastic resource for older machines or general servicing.

The rise in home sewing is undeniable, and that means more people are in need of quality local repair services. The global sewing machine market was valued at around USD 4.65 billion in 2025 and is expected to hit USD 6.20 billion by 2030. That's a lot of machines out there that will eventually need a tune-up! This growth just goes to show how vital it is to have a reliable technician on your contact list.

Decoding Repair Costs and Timelines

When you're searching for "sewing machine repairs near me," the two biggest questions always come down to money and time. How much is this going to set me back, and how long will I be without my creative partner? Getting a handle on the answers helps you budget both your finances and your project schedule.

First, it’s really helpful to understand the difference between a standard service and a specific repair. Think of a basic tune-up as an annual check-up for your machine. The technician will give it a thorough cleaning, oil the moving parts, and make sure everything is calibrated just right. This kind of preventative care usually has a flat fee, typically landing somewhere between $75 and $150 for a standard mechanical or computerized model.

But if your machine has a specific problem or needs new parts, that's when the costs start to climb.

Breaking Down Common Repair Costs

The final bill really depends on a few things. The brand of your machine, its age, and how complex it is all play a big part. For instance, fixing a vintage, all-metal workhorse might be more straightforward than troubleshooting a high-end computerized embroidery machine that needs special diagnostic tools.

While every shop is different, here are some realistic price ranges for common jobs you might run into:

- Timing Adjustments: This is a critical fix to get your needle and hook working in perfect harmony again. Expect this to add anywhere from $50 to $100 on top of a basic service fee.

- Tension Assembly Fixes: If your stitches are a complete mess, a faulty tension assembly is often the culprit. This repair can run from $40 to $90, depending on what parts need to be replaced.

- Feed Dog Replacement: When your fabric just isn't feeding through smoothly, these little guys might be worn out. Replacing them could add $30 to $60 to your bill.

Remember, these are just ballpark figures. I always tell people to ask for a detailed quote before giving the green light for any work. A good, transparent technician will be happy to walk you through the charges and get your approval before moving forward with any pricey part replacements.

Knowing about these variables helps you avoid that sticker shock when the final invoice comes. For a deeper dive, you can learn more about the cost of sewing machine repair in our detailed guide. It breaks down even more factors that can influence your bill, so you can make a truly informed decision.

Getting Your Machine Ready for Its Repair Visit

Before you pack up your machine and head to the shop, a little bit of prep work can make a world of difference. Trust me, taking a few minutes to get things in order helps the technician zero in on the problem much faster, which means you get your machine back sooner.

First things first, give your machine a quick surface cleaning. Grab a little brush and clear out any lint and dust bunnies you can see around the needle plate and in the bobbin area. That said, now is not the time to channel your inner mechanic. Resist the urge to start taking things apart—you could accidentally hide the real issue or, worse, create a new one.

The Power of a Good Note

This is the single most important thing you can do. A detailed note is like leaving a road map for your technician. It’s the best way to communicate what’s gone wrong when you’re not there to explain it in person.

Jot down a few key things:

- What's actually happening? Is it skipping stitches, making a clunking noise, or eating your fabric? Be as specific as you can.

- What were you sewing with? Tell them the type of fabric, the thread brand and weight, and the needle size and type. This context is gold.

- When does the problem show up? Does it happen right away? Only after you’ve been sewing for 20 minutes? When you sew fast?

Giving them this information lets the tech recreate the exact scenario that's causing you grief. It’s the fastest path to an accurate diagnosis.

Technician's Tip: "A clear note is like a road map to the problem. It saves me time and helps ensure I'm fixing the right thing the first time, getting your machine back to you sooner."

Finally, don’t forget to gather up the essentials. Make sure you bring the power cord, foot pedal, bobbin, and bobbin case. It's also a great idea to include the specific presser foot you were using when the trouble started. Having all these pieces allows the technician to do a complete and thorough test once the repair is done, making sure it’s truly ready to come home.

Keeping Your Machine Healthy After a Repair

Ah, that feeling of bringing your newly serviced machine home. It's like a fresh start! But that’s just the beginning. The real trick to avoiding another frantic "sewing machine repairs near me" search is building a solid maintenance routine right in your sewing room. Don't worry, this isn't about becoming a certified mechanic—it's about the little habits that protect your investment and keep everything humming along.

Honestly, think of it like your car. You wouldn't get an oil change and then just forget to check the tire pressure, right? Your sewing machine deserves that same consistent love and attention to perform at its best and sidestep any unnecessary wear and tear.

With so many of us embracing DIY and upcycling these days, a well-cared-for machine has become a badge of honor. It’s what powers our creativity, so it makes sense that we’re all getting more serious about proper upkeep.

Your Post-Repair Maintenance Checklist

The easiest way I've found to stay on top of things is to build a simple schedule. A few minutes of care after each project can save you hours of hair-pulling frustration later on. I promise.

- De-Lint After Every Project: Seriously, lint is the enemy! Grab a small brush and clear out the bobbin case and feed dog area after every big sewing session. It’s amazing how much fluff builds up in there.

- Change Your Needle Frequently: A dull or bent needle is the number one culprit for skipped stitches and damaged fabric. My personal rule of thumb is to swap it out after every 8-10 hours of sewing, or before starting a new big project.

- Use High-Quality Thread: It might be tempting to buy the cheap stuff, but don't do it! Cheaper threads are often incredibly linty, which leads to more gunk inside your machine and can even mess with your tension.

Your at-home maintenance routine is your first line of defense against common sewing machine problems. Empowering yourself with these skills not only saves money but makes you a more confident and self-sufficient crafter.

Here at bsewinn.com, we’re huge believers in this. Our online classes and resources are all about teaching you these exact skills, from basic cleaning to trickier tasks. For instance, if you're still fighting with your stitch quality even after a service, our guide on tension adjustment on a sewing machine can be a real lifesaver. When you master these small but mighty tasks, you extend the life of your machine and make sure every project is a joy from start to finish.

Still Have Questions? Let’s Talk Repair

Even after you've done your homework, it’s completely normal to have a few lingering questions when searching for "sewing machine repairs near me." Being curious is a good thing! It means you're making a thoughtful choice to get your beloved machine the best care possible.

Let's clear up some of the most common things sewists ask.

A big one is whether it's even worth fixing an older, less expensive machine. My answer usually comes down to two things: how much you love it and how it was made. That vintage all-metal machine you inherited? It can often be brought back to life for less than a new plastic model, and it'll probably outlive it, too. Always, always get an estimate first so you can weigh the cost of repair against the cost of a new machine.

Another frequent worry is how long it'll be in the shop. A simple tune-up might just take a few days, but if your technician has to order a specific part for a more complex fix, you could be looking at a few weeks. Don't be shy about asking for a timeline upfront. It just helps you plan your projects around it.

What’s Happening Behind the Scenes

It’s also helpful to know that what's available locally can be tied to bigger trends. The global market for sewing machines does trickle down to our local repair shops. For example, some areas see a lot of cheap, second-hand imported machines. Their build quality isn't always the best, which can mean they need more frequent trips to the repair shop. This is exactly why finding a trusted local technician is so important for keeping your machine humming along. You can actually read more about the growth of the sewing machine market on nextmsc.com.

The best advice I can give? Just talk to your technician. A good one will be happy to answer your questions, walk you through the repairs, and be totally transparent about costs and how long it will take. That's how you build confidence and trust.

At the end of the day, finding a great repair service is really about finding a person—a technician who gets your machine and understands what you need to bring your creative ideas to life.

Here at B-Sew Inn, our goal is to empower you at every single step of your sewing journey. We believe crafting should be joyful, not frustrating. That's why we don't just sell top-of-the-line machines; we provide the support you need to succeed. Through our custom sewing machine designs, comprehensive online classes, expert training, and an extensive library of resources, we help you master your craft and keep your equipment in fantastic shape. Come explore everything we have to offer and join a community that’s all about your success.