Just like you wouldn't drive a high-performance car for years without a tune-up, your sewing machine needs regular care to keep it humming along. This how-to guide is your secret to preventing those frustrating moments—think skipped stitches, tangled thread, and fabric jams. It’s all about creating a partnership with your machine, ensuring it's a reliable tool for every design you dream up.

Why Regular Maintenance Is Key to Great Sewing

Think of routine care not as a chore, but as an investment in your craft. Every single project you sew leaves behind tiny bits of lint and thread that work their way into your machine's delicate inner workings. Over time, all that gunk acts like sand in the gears, causing friction, wear, and eventually, a total breakdown.

Regular cleaning and oiling are your first line of defense. These simple habits ensure all those moving parts glide smoothly, which is the key to preventing the tangled messes and wonky stitches that can ruin a perfectly good piece of fabric. It’s the difference between reacting to problems and stopping them before they even start. For example, a well-oiled machine is essential for creating the perfect, even topstitching on a custom-designed handbag.

The Value of Proactive Care

Waiting until something goes seriously wrong is almost always more expensive than preventative care. A well-cared-for machine gives you perfect stitches every time, saving you heaps of time, frustration, and wasted material.

It’s no surprise that the sewing machine service industry has seen steady growth, especially after the 30% surge in home sewing machine sales during the pandemic. As more people discovered (or rediscovered) a love for sewing, the need for quality maintenance grew right along with it.

A well-maintained machine isn't just a tool; it's a dependable creative partner. It responds precisely to your guidance, allowing your vision to come to life without technical interruptions.

Here at bsewinn.com, we are committed to empowering crafters by helping you truly understand your equipment. Through our custom sewing machine designs, online classes, and extensive resources, we give you the knowledge you need for excellent upkeep, so you can focus on creating beautiful things.

Extending Your Machine's Lifespan

Keeping your sewing machine in top shape isn't all that different from maintaining any other valuable piece of equipment. Investing in regular service ensures your machine will be with you for years, protecting your initial investment and preserving a tool that might even hold a lot of sentimental value. Learn how the principle of extending a machine's lifespan through repair applies across various devices.

Mechanical vs. Computerized Machine Care

It’s easy to think a sewing machine is just a sewing machine, but that's not quite right. Their maintenance needs can be worlds apart, and understanding what’s under the hood is the first step to keeping your machine happy and knowing when to call for professional sewing machines service repairs.

Think of it like caring for a classic car versus a brand-new electric one. Both will get you down the road, but their engines require totally different kinds of attention.

Mechanical machines are the trusty workhorses of the sewing world. Their beauty is in their simplicity—all-metal gears, levers, and knobs that you can actually see and touch. This straightforward, hands-on design means their routine care is also pretty direct.

The heart of mechanical machine maintenance is physical. It's all about regular manual oiling of moving parts and diligently cleaning out lint from the gears and bobbin case. Because you can get to most of the components, you have a lot more control over the basic upkeep.

Computerized machines, on the other hand, are a whole different ballgame. They’re more like modern electronics, relying on circuit boards, sensors, and digital screens to pull off those amazing stitch patterns and automated functions. While this tech opens up a universe of creative possibilities, it completely changes how we approach maintenance.

Servicing Modern Sewing Technology

Instead of just worrying about physical gears, you're now dealing with software and sensitive electronic parts. A problem might not be a simple mechanical jam; it could be a sensor that's gone haywire or a software glitch. This calls for a different diagnostic approach, often involving special tools to communicate with the machine's internal computer. For instance, if you're trying to replicate an intricate embroidery design and the alignment is off, it's more likely a sensor issue than a physical one.

These advancements have completely reshaped what service looks like. Between 2025 and 2035, the computerized sewing machine market is expected to grow at a CAGR of 6.0% as these high-tech models become the norm. As features like programmable stitching and even AI integration become more common, the need for specialized troubleshooting knowledge will only grow with them.

Custom Designs and Expert Support

Here at bsewinn.com, we live and breathe both traditional and advanced custom sewing machines, helping crafters find the perfect tool for their vision. We understand that a high-tech machine can feel intimidating, which is why we offer extensive support through online classes and training resources. Our goal is to help you feel just as confident caring for a computerized model as you would a classic mechanical one, whether you're designing a simple quilt or an elaborate cosplay outfit.

For a deeper dive into how these two types stack up, check out our guide on computerized sewing machines vs. mechanical models. Knowing your machine's specific needs is the secret to keeping it running beautifully for years to come.

Signs Your Sewing Machine Needs a Professional

Your sewing machine has its own language. It hums along happily when everything is right, but it will definitely let you know when something’s wrong. Learning to listen is one of the most important skills you can develop as a crafter.

Think of it like this: every strange noise, every wonky stitch is a clue. Knowing how to read these signs helps you tell the difference between a simple fix you can handle in five minutes and a deeper issue that needs an expert eye for sewing machine service repairs.

Take skipped stitches, for example. Your first thought might be to change the needle—and you'd often be right! But if you pop in a fresh needle and the problem sticks around while you're trying to create a decorative stitch on a dress hem, you're likely looking at a timing or tension problem that's beyond a basic tune-up. Catching these things early saves your projects and prevents a small hiccup from turning into a big, expensive headache.

Decoding Your Machine’s Distress Signals

So, what are these "distress signals"? One of the most common—and alarming—is a loud, rhythmic clunking sound. That’s your machine screaming that its timing is off. The delicate dance between the needle and the hook is out of sync, and trying to fix that yourself without the right tools is a recipe for disaster.

What if your machine starts chewing up your beautiful fabric or the thread shreds constantly? Don't just blame the thread and move on. This could be a tiny, invisible burr on the needle plate or hook, snagging the thread as it passes. Or it could mean the feed dogs are misaligned. Both require a technician's steady hand to smooth out.

The better you can describe the problem, the faster a pro can fix it. Instead of just saying, "It's making a weird noise," try to be specific: "I hear a grinding sound when the needle bar moves down." That one sentence gives a technician a massive head start.

At bsewinn.com, we believe in empowering every sewist to feel confident and in control. Our online classes and training resources are built to help you understand your machine inside and out, so you can give it the care it deserves and get back to your creative designs.

Sewing Machine Symptom Checker

To help you decide whether to grab your screwdriver or your phone, we've put together this quick reference guide. It's a simple how-to for connecting what you're seeing and hearing with what might be going on inside your machine.

Here's a breakdown of common symptoms, their likely culprits, and whether you should tackle it yourself or call in the cavalry.

| Symptom (What You See or Hear) | Potential Cause | Recommended Action (DIY or Pro) |

|---|---|---|

| Loud, grinding, or clunking noises | Internal timing is off, a gear is stripped, or a part is loose. | Professional Service: These are signs of mechanical issues that require precise adjustments. |

| Consistently skipped stitches | Incorrect needle type, dull needle, or incorrect threading. If persistent, timing may be off. | DIY First: Change the needle and re-thread. If it continues, call a Pro. |

| Thread keeps breaking or shredding | Poor thread quality, incorrect tension, or a burr on a metal part (needle plate, hook). | DIY First: Re-thread with quality thread and check tension. If it persists, a Pro needs to find and smooth the burr. |

| Machine runs sluggishly or seizes | Lack of oiling, excessive lint buildup, or a motor issue. | DIY First: Thoroughly clean and oil the machine. If it doesn't improve, it's likely a motor or electrical problem needing a Pro. |

| Uneven or loose stitches | Incorrect tension settings, improper bobbin winding, or internal tension assembly problems. | DIY First: Re-wind the bobbin and adjust tension. If unresolved, a Pro needs to inspect the tension assembly. |

Hopefully, this little chart demystifies some of those frustrating moments and gives you a clear path forward. Knowing when to ask for help is just as important as knowing how to thread the needle.

When to DIY and When to Call a Technician

Knowing your machine is one thing, but knowing your own limits is just as important. It’s fantastic to feel empowered enough to handle the little day-to-day upkeep tasks that keep your machine humming along. But let’s be honest, trying to tackle a complex internal repair without the right know-how can turn a tiny hiccup into a total nightmare—and a much bigger bill.

The real key is drawing a line in the sand between what you can confidently handle at home and when it’s time to pick up the phone for sewing machines service repairs.

Think of at-home maintenance as your machine's daily wellness routine. These are the simple, repeatable habits that stop bigger issues from ever cropping up. Getting comfortable with them not only extends your machine’s life but also helps you build a real connection and understanding of how it works.

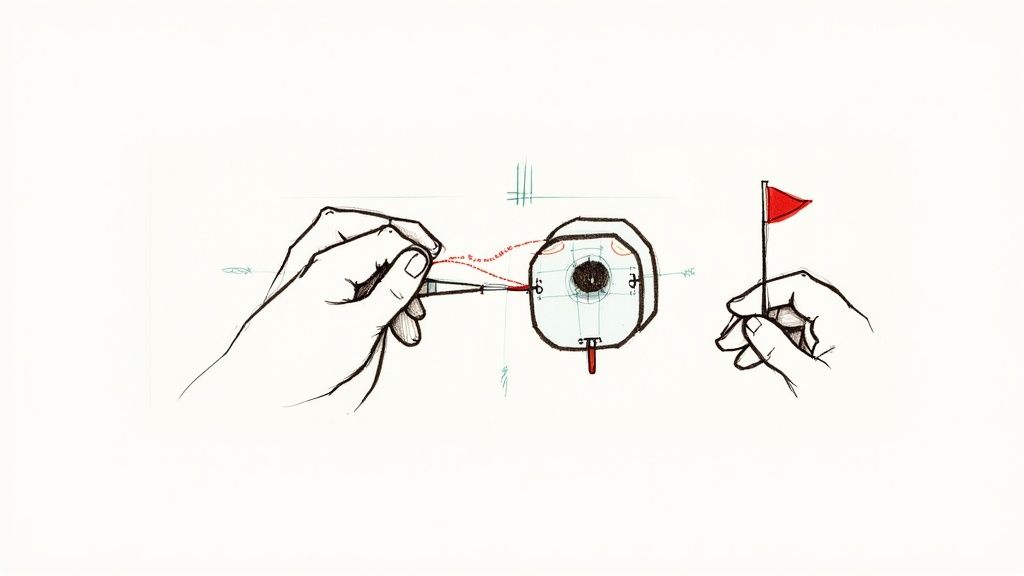

Your Essential DIY Maintenance Checklist

You don't have to be a mechanical whiz to keep your machine in great shape between professional tune-ups. Every sewer should feel comfortable with these non-negotiables.

- Deep Cleaning the Bobbin Area: Lint is the enemy! After every 8-10 hours of sewing, that fluff builds up around the bobbin case. A quick sweep with a small brush can prevent a world of tension headaches.

- Changing the Needle: A fresh needle is the cheapest insurance you can buy for your projects. Make it a habit to swap it out after every big project or 8 hours of use to avoid skipped stitches and snagged fabric.

- Basic Oiling: If you're using a mechanical machine, a single drop of sewing machine oil on the moving parts is like magic. It keeps everything gliding smoothly. Just be sure to check your manual first to see exactly where and how often to do it.

- Simple Tension Tweaks: Getting comfortable with the upper thread tension dial is a fundamental sewing skill. Often, a tiny turn is all it takes to fix wonky-looking stitches.

Mastering these little tasks isn't just about maintenance; it's about building a partnership with your machine. At bsewinn.com, our goal is to empower you to be your machine's first line of defense with helpful resources, online classes, and training.

Red Flags That Demand a Technician

While we love a good DIY fix, some problems are clear signals that your machine needs an expert. Trying to muscle your way through these issues yourself can cause serious, sometimes irreversible, damage.

If you spot any of these, it's time to call in the pros:

- Timing Adjustments: Hear a loud clunk every time the needle goes down? That’s a tell-tale sign the timing is off—the delicate dance between your needle and hook is out of sync. This requires specialized tools and an expert's touch.

- Motor or Electrical Problems: Any weird smells, struggles to power on, or a motor that sounds like it’s giving up the ghost are serious red flags. For safety alone, this is a job for a qualified technician.

- Internal Gear or Part Replacement: If you suspect a stripped gear or a broken internal part, step away from the screwdriver. A professional has access to the right parts and knows the complex puzzle of taking your machine apart and putting it back together correctly.

This focus on repair over replacement is becoming more common. As people embrace upcycling and more sustainable habits, the demand for sewing services is growing. It's a trend that's having a real impact on the sewing machine market on archivemarketresearch.com. And if you need a hand with those more common issues, don't forget to check out our sewing machine troubleshooting guide.

What to Expect from a Professional Repair Service

It can be a little nerve-wracking to hand your beloved sewing machine over to a complete stranger. Trust me, I get it. But knowing what to expect from a professional repair process can help turn that anxiety into confidence. A good technician follows a clear, straightforward procedure to get your machine humming again, without any nasty surprises along the way.

The whole thing usually kicks off with an initial diagnostic. Think of it like a check-up at the doctor's office. The technician will give your machine a thorough once-over to figure out exactly what’s causing the trouble. They’ll look beyond the obvious symptoms to spot any underlying issues that could become bigger problems down the road.

After this initial look-see, you should get a clear, detailed cost estimate. This is a non-negotiable step in professional sewing machines service repairs. It makes sure you understand all the charges before they even pick up a screwdriver. Any trustworthy shop will be completely upfront about these costs.

The Repair and Return Process

Once you give them the green light on the estimate, the technician gets down to business. This isn’t just about fixing the main problem; it also includes a general service—think a deep clean, proper lubrication, and a full calibration to get everything running in perfect harmony. Quality repairs always depend on using the right parts for your specific machine.

Before you commit, it’s always smart to ask a few key questions. This helps you make an informed choice and ensures you’re getting the best bang for your buck.

- Do you use genuine manufacturer parts? Using the real deal ensures your machine runs smoothly and the repair lasts, which is especially critical for those fancy computerized models.

- Is the diagnostic fee applied to the final repair cost? Lots of shops will credit this initial fee toward the total bill if you decide to go ahead with the repair.

- What is the warranty on your repair work? A reputable tech will always stand by their work with a warranty. It's your peace of mind.

Getting a handle on potential expenses ahead of time is a huge relief. For a deep dive into what you might expect to pay, we've put together a comprehensive guide on the cost of sewing machine repair.

Timeliness and Communication

Finally, a truly professional service respects your time. While some complex repairs naturally take longer, the shop should give you a realistic timeframe for when you'll get your machine back and keep you in the loop. When you're picking a repair service, remember that efficiency matters—studies show the true cost of long customer waits can really impact satisfaction.

At bsewinn.com, we believe that empowering crafters goes beyond selling custom machines and offering online classes. We want you to feel confident in every part of owning a machine, and that includes navigating the repair process. Knowing what to expect ensures your machine gets the expert care it truly deserves.

Got Questions About Sewing Machine Repair? We've Got Answers

Even when you're doing everything right, questions about sewing machine service and repairs are just part of the sewing life. To help you feel a little more confident about caring for your machine, I've rounded up some of the most common questions I hear from fellow crafters. Think of this as your quick-reference guide for keeping your creative partner happy and humming.

We're going to get into the practical stuff that really matters, from how often you really need a tune-up to whether that vintage machine from grandma is worth fixing. My goal here is to give you clear, straight-up answers that help you on your sewing journey.

How Often Does My Machine Need Professional Service?

Honestly, the real answer depends entirely on how much you sew. For a lot of hobbyists who pull out their machine a few times a month, getting a professional tune-up every two years is a great rule of thumb. It's enough to keep everything properly calibrated and running smoothly.

But if you’re a sewing fanatic who's at your machine every week, or you're constantly tackling heavy-duty fabrics like denim and canvas, you’ll want to bump that up to an annual service. And for those of you running a small business or sewing daily? Plan on a professional service every six to twelve months. It's absolutely essential for preventing frustrating (and costly) downtime.

Just to be clear, this is for the deep-cleaning and calibration that only a pro can do. Your own basic cleaning, especially around the bobbin area, should happen way more often—I recommend a quick de-fluff after every 8-10 hours of sewing to stop lint from building up.

Is It Worth Repairing an Older Sewing Machine?

In so many cases, yes! It really comes down to the machine's quality and its value—both what it's worth and what it means to you. If we're talking about a super inexpensive, entry-level modern machine, a major repair bill might actually cost more than just buying a new one.

On the other hand, those vintage all-metal mechanical machines? They were often built like tanks. These are fantastic candidates for repair because their rock-solid construction means they can literally last for generations with the right care. And if a machine has sentimental value, investing in a repair can keep a treasured family heirloom stitching for years to come.

What Is the Most Common Sewing Machine Problem?

You might be surprised by this one. Technicians pretty much all agree: the number one culprit behind most sewing machine issues is a lack of basic cleaning. That's it! Lint buildup in the bobbin area is the most frequent troublemaker. All that fluff acts like a sponge, soaking up oil and creating friction that can cause parts to grind and even seize up.

Coming in at a close second is using the wrong needle. A dull, bent, or incorrect type of needle for your fabric is a classic cause of skipped stitches and shredded thread. Worse, if it hits the hook mechanism, it can completely throw off your machine's timing.

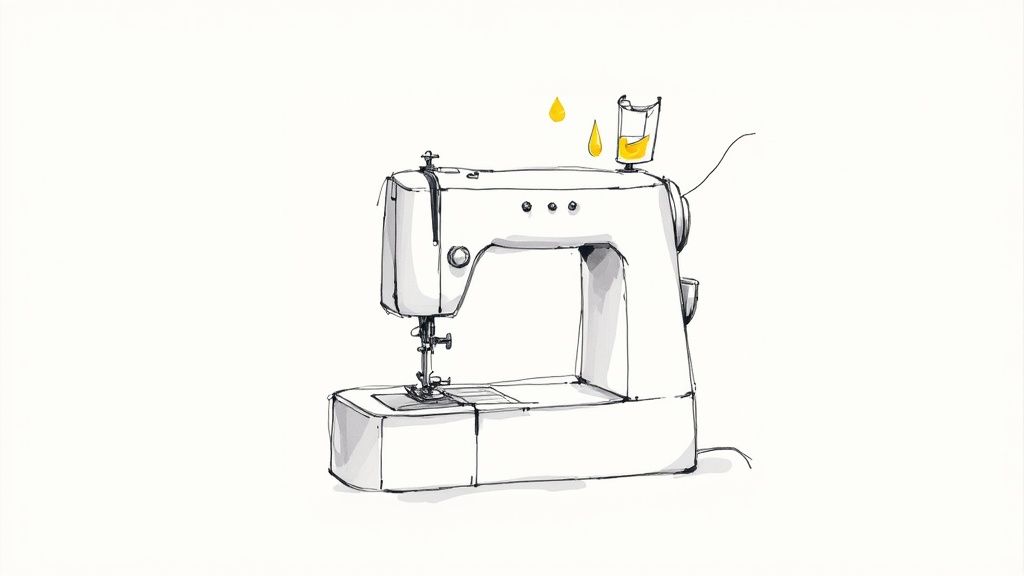

Can I Use Any Household Oil on My Machine?

Please, no! This is one of the most critical things to know. You should only ever use oil that is specifically labeled "sewing machine oil." It's a clear, lightweight, and super-refined lubricant designed perfectly for the delicate, high-speed parts inside your machine.

Things like WD-40, 3-in-1 oil, or other household lubricants are way too thick. They're sticky and will attract dust and lint, eventually turning into a gunky sludge that gums up the entire machine. Using the wrong oil is a surefire way to land yourself a much more expensive and complicated professional repair down the road. Sticking to the right stuff is such an easy way to protect your investment.

At bsewinn.com, we're all about empowering crafters at every stage of their journey. From our custom sewing machine designs to our huge library of online classes and training resources, we provide the support you need to create with total confidence. Come explore our world of sewing, quilting, and embroidery to find the tools and knowledge that will bring your vision to life.

Discover your next creative partner at https://www.bsewinn.com.