A good sewing thread size guide is your secret weapon. It's a foundational "how-to" for creating any sewing machine design, helping you pick the perfect thread thickness for whatever fabric you're working with. Getting this right is the key to achieving strong, clean, professional-looking seams every single time, whether you're making a simple tote bag or an intricate quilt.

For example, a standard 40 Wt (weight) polyester thread is a fantastic all-rounder for everyday projects with fabrics like cotton. But if you're working on a custom design with delicate silks, you'll want to switch to a finer 60 Wt thread. Getting this right from the start helps you dodge frustrating issues like fabric puckering, skipped stitches, or weak seams that just don't hold up—the kind of details that can make or break a design you've poured your heart into.

Why Your Thread Choice Matters

Walking up to a wall of thread spools can feel a little overwhelming. All those numbers and codes! But trust me, figuring out what they mean is one of the biggest steps you can take to elevate your sewing projects from looking "homemade" to truly professional. The right thread makes sure your seams are not just pretty, but tough enough for real life. At bsewinn.com, we are committed to empowering crafters by providing the knowledge to master these details, which is why we offer extensive resources like this guide.

I like to think of thread as the skeleton of a garment or project. If you use thread that’s too thin for a heavy fabric like denim on a backpack design, the seams will be the first thing to give out under stress. On the flip side, a thread that’s too beefy for a delicate chiffon dress design will create bulky, ugly seams that completely ruin the fabric's natural drape.

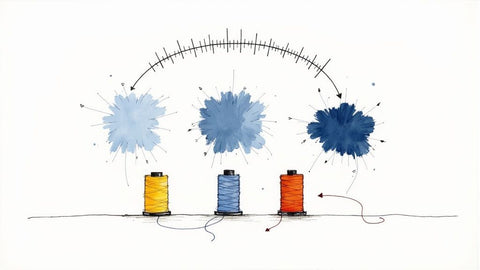

The Impact of Thread Sizing

Matching your thread to your fabric is a foundational skill that pays off big time in the quality of your finished piece. It all comes down to the thread's "size," or thickness, which affects both its strength and how it behaves with different materials.

One of the most common measurement systems you'll see is Tex. It’s pretty straightforward: Tex measures the weight in grams of 1,000 meters of thread.

So, a Tex 30 thread simply means that 1,000 meters of that thread weighs 30 grams. The higher the Tex number, the thicker and stronger the thread.

As a tangible example, lightweight garment designs do best with thin threads like Tex 12–20, while heavier fabric projects like a canvas tote bag demand stronger Tex 40–60 threads. If you want to dive even deeper into the different sizing systems, the folks at bycurated.com have a great breakdown.

Here at bsewinn.com, we believe that mastering the fundamentals is what truly empowers creators. It’s why our online classes and resources focus on building confidence from the ground up, whether you're choosing a thread or bringing your own custom sewing machine designs to life. We provide the support and extensive resources you need to succeed.

Our goal is to take the mystery out of these technical details so you can get back to the fun part—creating! Think of this guide as your go-to framework for picking the perfect thread every single time.

Decoding Thread Sizing Systems Like an Expert

Have you ever stared at a spool of thread and felt like you were trying to crack a secret code? All those numbers—like '40 Wt' or 'Tex 30'—can feel a little mysterious, but they're the key to choosing the perfect thread for your project. Once you get the hang of the three main sizing systems, you'll be able to grab any spool off the shelf with total confidence, ready to tackle any design.

Think of these systems as different languages that all describe the same thing: how thick a thread is. Each one has its own logic, but they’re simpler than they look. Let’s break them down.

The Weight System (Wt)

The Weight (Wt) system is probably the one you see most often, especially for home sewing. It’s a little counterintuitive at first, but the rule is simple: the higher the number, the thinner the thread.

So, a 60 Wt thread is gossamer-fine, perfect for creating delicate designs with silks or tiny, detailed embroidery. On the other end, a 30 Wt thread is much beefier, the kind you'd use for sturdy topstitching on a denim jacket or for seams you really want to show off. A good middle-of-the-road option is a 50 Wt thread, like what you’ll find in the Mettler Metrosene collection, which is a fantastic all-rounder for most medium-weight fabrics.

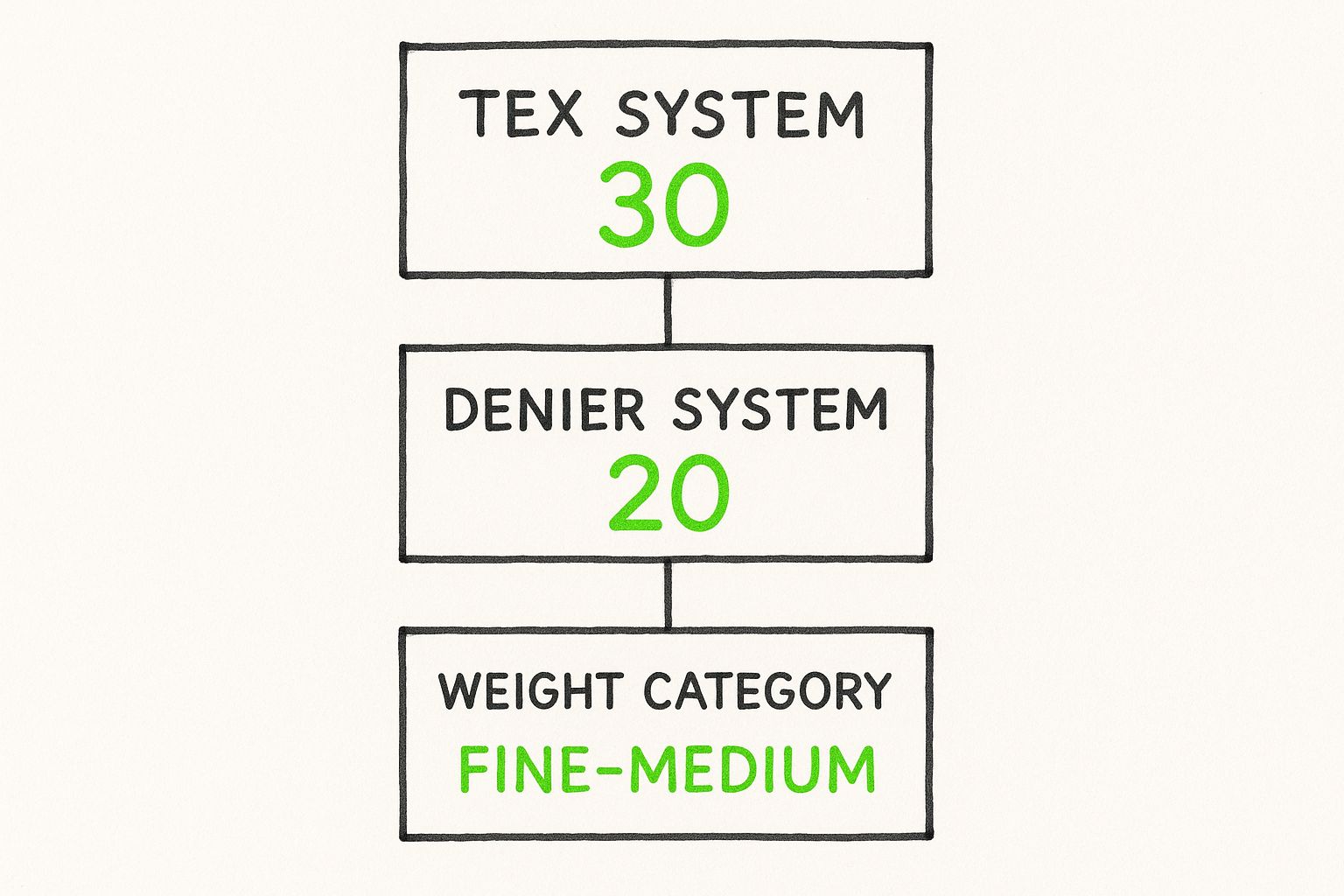

The Tex and Denier Systems

Next up is the Tex system. This one is a more modern, standardized measurement used a lot in industrial settings, but it's popping up more for home sewers, too. Unlike the Weight system, Tex is direct: the higher the Tex number, the thicker and stronger the thread. It’s that simple. The number tells you the weight in grams of 1,000 meters of thread. A Tex 30 thread means 1,000 meters of it weighs 30 grams.

Finally, we have the Denier (d) system. It works just like Tex but is more common for synthetics like polyester and rayon, especially in the embroidery world. It measures the weight in grams of 9,000 meters of thread. And just like Tex, a bigger Denier number means a thicker thread.

Key Takeaway: For Weight (Wt), bigger numbers mean thinner thread. For Tex and Denier, bigger numbers mean thicker thread. Getting that simple difference down is the first big step to mastering your materials.

This diagram is a great way to see how these different sizing systems can all describe a similar thread.

As you can see, a Tex 30 thread and a Denier 270 thread both fall into that 'Fine-Medium' category. They're just different ways of measuring the same thing.

Thread Sizing Systems Conversion Chart

To make things even clearer, I've put together a little cheat sheet. This table is a how-to guide for translating between the different systems so you can see how they line up for common project designs.

| Common Use | Weight (Wt) | Tex Equivalent | Denier Equivalent |

|---|---|---|---|

| Lace, Appliqué, Quilting | 60 Wt | Tex 15 | Denier 135 |

| General Sewing, Piecing | 50 Wt | Tex 25-27 | Denier 225-243 |

| Topstitching, Quilting | 40 Wt | Tex 30 | Denier 270 |

| Heavy Topstitching, Denim | 30 Wt | Tex 40-50 | Denier 360-450 |

| Upholstery, Canvas | 12 Wt | Tex 80-100 | Denier 720-900 |

This chart isn't about memorizing numbers; it's about building an intuition. Soon enough, you'll just know that a 40 Wt thread is a great choice for making the stitches on your quilted wall hanging design pop.

Here at bsewinn.com, we believe that understanding these details is what turns a hobby into a craft. We are committed to empowering you to move past any confusion and focus on what you love—creating beautiful, lasting projects. Knowing your thread is a foundational skill that makes every single stitch better.

Matching Thread to Your Fabric and Needle

The real secret to a perfect stitch is getting your thread, fabric, and needle to play nicely together. Think of them as a team of three. When they're all in sync, your sewing is smooth, strong, and just plain effortless. But when one of them is off, you start running into those frustrating problems we all know too well—skipped stitches, puckered seams, and constantly breaking thread.

Nailing this combination is one of the most practical skills you can pick up. It completely transforms the quality of your work, making sure your seams aren't just holding things together but actually look like they belong. The whole point is for the thread to become a seamless part of the fabric, not something that just sits awkwardly on top.

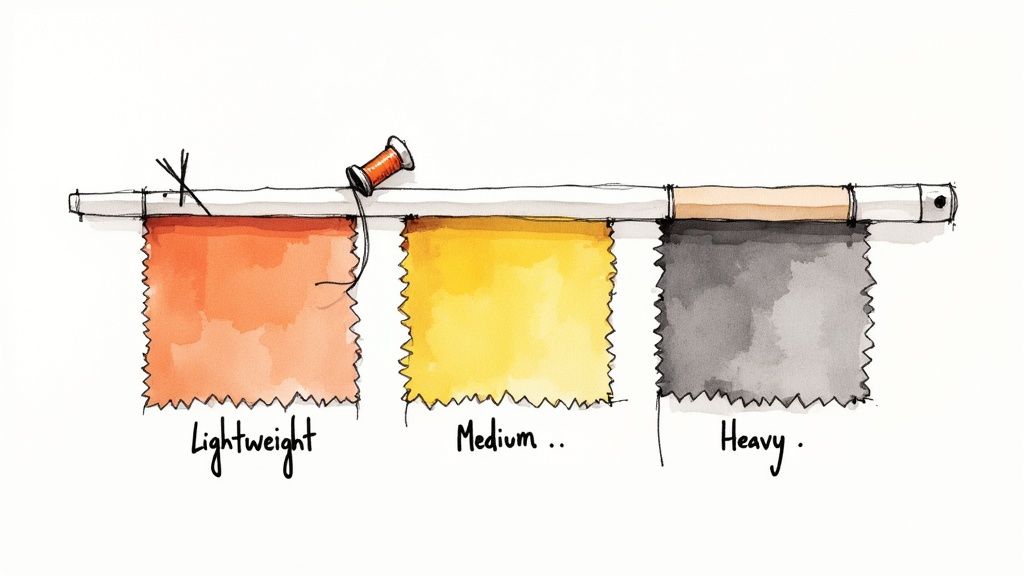

The Fabric and Thread Partnership

The main rule of thumb here is pretty simple: your thread should match the weight of your fabric. Heavy, sturdy fabrics need a strong, thick thread. On the flip side, delicate fabrics need a fine, lightweight thread to match. If you try to use a heavy thread on a lightweight fabric, you’ll end up with bulky, stiff seams that can totally ruin the fabric's natural drape.

Here are some tangible examples of how to replicate this in your own designs:

- Delicate Fabrics: If you're creating a lingerie design with silk charmeuse or a sheer organza overlay on a dress, a fine 60 Wt polyester or silk thread is your best friend. Its slender profile will create seams that are practically invisible and won't overpower the material.

- Medium-Weight Fabrics: For quilting cottons, linens, and most everyday apparel fabrics used in designs like a simple skirt or pillowcase, a versatile 50 Wt or 40 Wt all-purpose polyester or cotton thread is what you'll reach for most often. This is the true workhorse of the sewing room.

- Heavy-Duty Fabrics: When you're tackling a tough design like a denim jacket, canvas tote bag, or upholstery fabric for a cushion, you need a thread that won't back down. A robust 30 Wt thread or even a Tex 70 bonded nylon gives you the strength needed for seams that will last for years.

This idea of balance is really a cornerstone of professional-level sewing. When you get this harmony right, it separates a good project from a truly great one. It’s how you prevent the most common sewing machine headaches before they even get a chance to start.

Bringing the Needle into the Mix

The final piece of this puzzle is your sewing machine needle. The needle's job is to poke a hole in the fabric that’s just big enough for the thread to slide through without getting snagged or damaged. If the needle's eye is too small, it'll shred your thread. If the needle is too big for the fabric, it’ll leave behind ugly, noticeable holes.

Your needle size should always correspond to your thread size. For instance, a fine 60 Wt thread is a perfect match for a small needle, like a 65/9 or 70/10 Microtex, especially on delicate fabrics. That heavy 30 Wt topstitching thread, however, needs a much bigger needle—think a 100/16 or 110/18—to make a large enough hole. If you want to dive deeper into this, you can check out our guide on choosing the right needle.

Thankfully, modern manufacturing has made this matching game more reliable than ever. Today's threads are made with incredible precision, with consistent diameters ranging from less than 0.1 mm for super-fine embroidery thread to 0.5 mm or more for heavy-duty types. This standardization means that when you follow a thread size guide, you can trust you’ll get predictable, high-quality results every time.

Here at bsewinn.com, we're all about empowering you with this kind of foundational knowledge. Through our online classes and extensive resources, we provide the support and training to master these balanced setups for any project you can dream up, helping you bring your unique custom sewing machine designs to life with a truly professional polish.

Alright, picking the right thread size is a huge win, but let's talk about what the thread is actually made of. This is just as critical.

Think of it like this: size gives you the right strength for the job, but the material—the actual fiber—gives you the right behavior. We're talking stretch, durability, and even the final look. Nailing this combo is what makes your projects not only look fantastic off the machine but also hold up beautifully over time.

So, is classic cotton always the answer? When should you grab that super-strong polyester? Figuring out this balance is something we dive deep into in our online classes at bsewinn.com. With our support and training, you can master these foundational skills for making work that looks and feels truly professional.

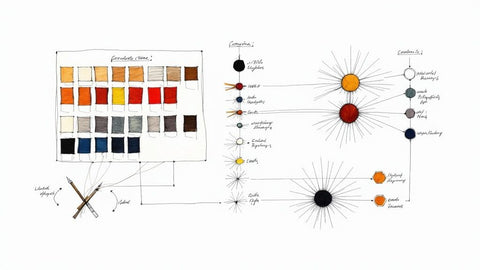

The Classics: Cotton and Polyester

For ages, these two have been the absolute workhorses of the sewing room. Each one has its own personality and is perfect for different things.

-

Cotton Thread: This is your go-to natural fiber. It’s soft, has a lovely low-sheen matte finish, and absolutely no stretch. Quilters adore it, especially when working with 100% cotton fabrics for their quilt designs, because the thread wears down at the same rate as the fabric itself. A 50 Wt cotton is a quilter's best friend.

-

All-Purpose Polyester: This is probably the thread you see most often. Polyester is incredibly strong, built to last, and has a little bit of stretch. That slight give makes it a dream for sewing clothes, especially with knit fabrics. The thread moves right along with the fabric, which means no more popped seams when you stretch. A perfect example is using it for a t-shirt or legging design.

The demand for all these different types of thread is just massive. To give you an idea, the sewing thread market was valued at an estimated USD 3.69 billion back in 2024 and is only expected to grow. That number reflects every single type of thread out there, from the delicate stuff for garments to the tough-as-nails industrial threads.

Heavy-Duty and Specialty Fibers

Sometimes, your project needs to be tough. Really tough. That’s when you need to look beyond the everyday cottons and polyesters and bring in the specialists.

Heavy-duty nylon is the undisputed champ for designs that are going to take a beating—think backpacks, upholstery, or outdoor gear. It’s exceptionally strong and stands up to abrasion like nothing else. For these kinds of jobs, a bonded nylon thread is a must for long-term durability.

And as more of us are thinking about our environmental footprint, some really cool sustainable materials are popping up. For example, the Madeira Sensa Green Softbox gives you a fantastic, eco-conscious option without sacrificing quality. Here at bsewinn.com, we love giving crafters access to both the time-tested traditional materials and these exciting new options, all while providing the resources you need to choose with confidence.

Selecting Thread for Specialty Sewing Projects

Once you venture beyond straightforward garment sewing, you quickly discover that different crafts demand their own specific tools—and thread is no exception. The all-purpose thread that works wonders on a cotton dress design just isn’t going to cut it for a quilt, and it will be an absolute disaster in a high-speed embroidery machine.

Picking the right thread for these special projects is about more than just looks; it’s about making sure your hard work is strong, durable, and structurally sound. Whether you're quilting, embroidering, or wrestling with heavy-duty upholstery, the thread you choose is a make-or-break decision. This is where really knowing your materials separates the good from the great.

Thread for Quilting Projects

For quilters, thread choice really breaks down into two main jobs: piecing the quilt top and the actual quilting that goes through all the layers. When you're piecing the blocks, the name of the game is creating a strong seam that lays flat and doesn't add any extra bulk.

This is exactly why 50 Wt cotton thread is the hands-down favorite for piecing. It’s fine enough to disappear into the seam allowance but tough enough to hold everything together through years of snuggling and washing. A tangible example is using it to assemble the blocks for a classic log cabin quilt design.

When it's time to do the actual quilting, you’ve got a lot more room to play. Many quilters stick with the same 50 Wt thread for a subtle, blended look. But if you want your stitches to pop and become part of the design, stepping up to a thicker 40 Wt or even 30 Wt thread is a fantastic way to create beautiful, decorative topstitching.

Machine Embroidery Thread Essentials

Machine embroidery is a whole different world. In this craft, the thread isn’t just a structural element; it is the art. The undisputed standard here is 40 Wt thread. It hits that perfect sweet spot—fine enough to capture intricate details in a custom monogram design, yet thick enough to provide lush, solid color.

You'll generally run into two superstar thread types for machine embroidery:

- Polyester Embroidery Thread: This is your go-to for shine and serious durability. Polyester can handle frequent washing, and it’s even bleach-resistant, making it perfect for things like towels, kids' clothes, or any design that's going to see a lot of action.

- Rayon Embroidery Thread: Rayon has a gorgeous, silky sheen that’s a little softer than polyester. Many embroiderers reach for it when they want a classic, high-end finish that really elevates a design.

At bsewinn.com, we know that jumping into a new craft like embroidery can feel a bit overwhelming. That’s why we offer everything from online classes to hands-on training to help you get comfortable with the tools of your new passion. Our commitment is to empower you by taking the mystery out of the technical side of sewing so you can just focus on bringing your creative ideas to life.

Threads for Upholstery and Bag Making

When you’re creating a design that needs to survive some serious abuse, your thread has to be up to the challenge. For projects like upholstery, outdoor gear, or sturdy bags, your standard sewing thread just won’t last. The seams would give out in no time under that kind of stress.

For these tough-as-nails jobs, a bonded nylon or bonded polyester thread is an absolute must. A super reliable and common size for these projects is Tex 70 (you might also see it labeled as #69). This stuff is incredibly strong, resists abrasion, and is built to last. Using the right heavy-duty thread is the only way to ensure your most ambitious custom designs are ready for anything.

Got Questions About Thread Size? Let's Unwind Them.

Diving into the world of sewing thread sizes can feel a little confusing, and that's okay. Even sewers who have been at it for years will pause to double-check their choices. Think of this little Q&A as the final piece of this comprehensive how-to guide, helping you pick the right thread, sew with more confidence, and get that beautiful, professional finish on every single project.

Getting these details right is what separates a good project from a great one. It's how you avoid those frustrating little hiccups, make the most of the thread you already have, and turn a potential headache into a flawlessly finished piece.

What Happens If You Use the Wrong Thread Size?

Oh, this is a big one. Using the wrong thread size is the secret saboteur behind so many common sewing frustrations. It’s not just about looks; it’s about the actual strength and structure of your seams. Getting this wrong can completely undermine a project you’ve spent hours on.

It usually goes wrong in one of two ways:

- Thread That's Too Thick: Ever tried using a heavy denim thread on a floaty fabric like chiffon for a summer dress design? The thread is just too bulky and powerful for the delicate material. This is what causes that awful puckering, where the fabric bunches up along the seam. It creates a stiff, clumsy-looking stitch line that completely ruins the natural drape of your fabric.

- Thread That's Too Thin: On the flip side, using a fine thread on a heavy-duty fabric like canvas or denim creates a seriously weak seam. It simply won't have the muscle to handle any stress. For designs like bags or jackets that get a lot of use, this is a recipe for disaster—those seams are likely to pop right open.

A mismatch between your thread and fabric is probably the #1 cause of stitch problems. Making sure they're a balanced pair is a fundamental skill that solves issues like skipped stitches and breaking thread before you even start sewing.

At bsewinn.com, our online classes and training really hammer these fundamentals home. We are committed to empowering you to create beautiful, long-lasting projects by clearing up these core concepts, especially when you're working on your own custom sewing machine designs. Our extensive resources are here to support you.

Can I Use the Same Thread in the Bobbin and on Top?

For probably 95% of your sewing, the answer is a big, confident yes! Using the exact same thread in both the top spool and the bobbin is the standard way to go. It’s what creates a perfectly balanced stitch, where the top and bottom threads meet and lock right in the middle of your fabric layers. This gives you a seam that looks great and is super strong.

However, there are a few creative exceptions. For a fancy machine embroidery design or decorative topstitching on a jacket, you might want to use a gorgeous, thicker thread on top for everyone to see. In that case, you'd pair it with a much finer, lighter thread in the bobbin (often called bobbinfil). This trick cuts down on bulk on the underside and helps your machine maintain smooth tension with those specialty threads.

How Can I Identify the Size of an Unmarked Spool?

We’ve all been there—you find a spool of thread in your stash, but the label is long gone. Don't just toss it in the mystery pile! There are a couple of simple tricks to figure out what you're working with.

First, just eyeball it. Grab a spool of thread you know the size of, like a standard 40 Wt all-purpose polyester. Pull a strand from each and hold them side-by-side against a piece of white paper or a contrasting background. You can usually see a pretty clear difference. Is your mystery thread thicker? It might be a 30 Wt. Thinner? You could be looking at a 50 Wt or 60 Wt.

For a more hands-on method, give the wrap test a try. Tightly wrap the thread around a ruler, making sure the strands are touching but not overlapping. Now, count how many times the thread wraps within a single inch. A finer thread will have more wraps. For instance, a 40 Wt thread usually wraps around 40-50 times per inch, while a super-fine 60 Wt might wrap 60-70 times. It's not lab-perfect, but it’s a surprisingly good way to get a solid estimate and put that mystery thread to good use.

At bsewinn.com, we're here to cheer you on at every stage of your creative journey. Whether you need the right supplies or expert advice from our huge library of resources, we want to help you bring your ideas to life. Come explore our collection of machines, threads, and accessories to find exactly what you need for your next masterpiece. Visit us at https://www.bsewinn.com to learn more.