A good thread weight chart is one of those tools you don't know you need until you really need it. It’s what lets you make sense of all the different numbers you see on a spool of thread, ensuring you grab the right one for your project. Think of it as a translator—it helps you compare apples to apples when one spool is labeled 50wt and another is Tex 27. Getting a handle on these numbers is the first step to creating professional-looking, durable stitches for any sewing machine design you can imagine.

Why Understanding Thread Weight Is Crucial

Have you ever had a project where the stitches just looked bulky and out of place? Or maybe you've dealt with the frustration of thread that just keeps snapping for no reason. More often than not, the culprit is the thread's weight. Choosing the correct thread thickness is just as critical as picking the right fabric or needle, and it has a huge impact on the final quality of your work.

Here at B-Sew Inn, we're committed to empowering you through our custom sewing machine designs, giving you the knowledge needed to bring creative ideas to life. Whether you're doing delicate embroidery on a Baby Lock machine or piecing sturdy quilting seams, the right thread makes sure your project is built to last. Our goal is to empower your creativity through tangible examples, extensive resources like our online training, and a community that’s always there to cheer you on.

The Challenge of Multiple Systems

One of the biggest headaches for any sewist is the fact that there’s no single, universal standard for measuring thread. You’ll usually run into three different systems, and each one has its own logic.

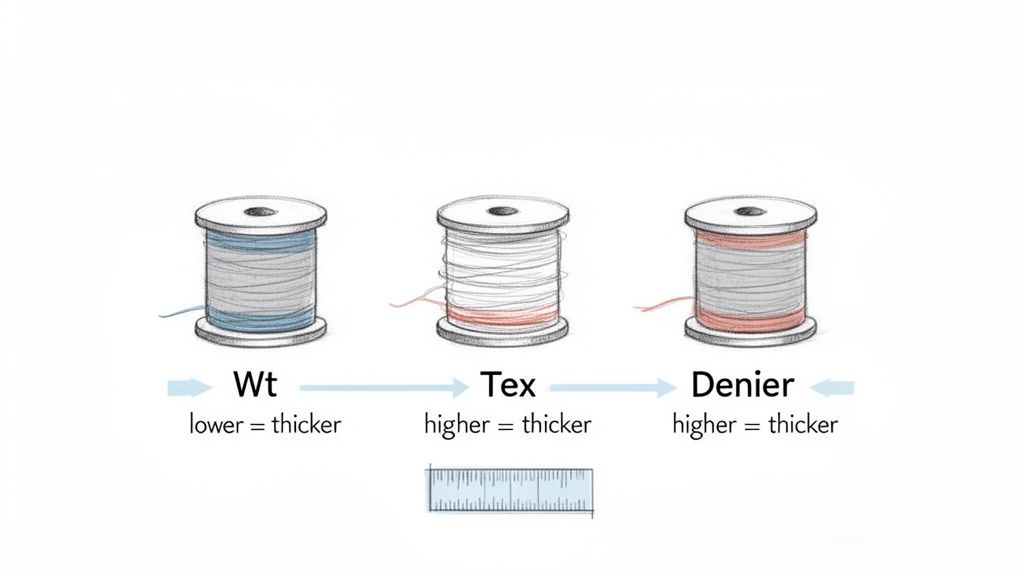

- Weight (Wt): This is probably the most common system you'll see in the quilting world. It works on an inverse relationship—the lower the number (like 30wt), the thicker the thread.

- Tex: This system is much more straightforward. It has a direct relationship, so the higher the number (like Tex 40), the thicker the thread. Easy peasy.

- Denier (Den): Similar to Tex, this is another direct system. A higher number means a thicker thread. You'll see this a lot with embroidery and serger threads.

This guide is here to clear up the confusion. We'll demystify these systems with a clear thread weight chart and real-world examples you can replicate. Once you get the hang of this, you’ll be able to pick your thread with confidence, preventing a lot of common frustrations and seriously leveling up your sewing game.

Getting this down is your key to unlocking flawless stitches. You'll be able to walk into any craft store, look at a spool, and know exactly how it will behave in your machine for whatever design you're planning to make.

Decoding The Three Major Thread Measurement Systems

To really get the most out of a thread weight chart, you first need to speak its language. The thread world basically runs on three different measurement systems—Weight (Wt), Tex, and Denier—and each one tells you something different about how thick a thread is. Getting a handle on these is the secret to getting those beautiful, consistent results you’re always chasing in your designs.

Once you know this stuff, you can stop guessing. Whether you're piecing a delicate heirloom quilt or topstitching a durable bag, you'll be able to grab the perfect thread every single time. It's all about making sure your custom sewing machine projects turn out just how you pictured them.

The Weight (Wt) System Explained

The most common system you'll run into, especially if you're a quilter, is the Weight (Wt) system. The logic here can feel a little backward at first because it’s an inverse scale. It’s simple, though:

- A lower number, like 30wt, means a thicker thread.

- A higher number, like 100wt, means a much finer thread.

So, how does that work? It's all based on how many kilometers of a thread it takes to weigh one kilogram. For a 40wt thread, it takes 40 kilometers of that thread to hit the 1kg mark. A thicker 30wt thread is heavier, so it only takes 30 kilometers to reach that same weight.

Here's a practical example: If you're creating a custom tote bag and want a bold, decorative topstitch that really pops, you’d reach for a thick 30wt thread. But for a delicate baby blanket with almost invisible appliqué stitches, you’d want a fine 80wt or 100wt thread so the fabric can be the star of the show.

Understanding The Tex System

The Tex system is way more straightforward, which is why it’s become a global standard. With Tex, the rule is simple: the higher the Tex number, the thicker the thread. No inverse logic to worry about here.

This system measures the weight in grams of 1,000 meters of thread. So, if 1,000 meters of a thread weighs 27 grams, it’s labeled Tex 27. This makes comparing threads a breeze—a Tex 40 thread is obviously thicker than a Tex 27. You'll see Tex used a lot for all-purpose sewing and quilting threads.

Cracking The Denier Code

Just like Tex, the Denier (Den) system is another direct measurement where a higher number means a thicker thread. You'll see this system most often with synthetic fibers like polyester and rayon, especially for embroidery and serger threads.

The only real difference between Tex and Denier is the length being measured. Denier is calculated by the weight in grams of 9,000 meters of thread. So, if 9,000 meters of an embroidery thread weighs 120 grams, it’s a 120 denier thread.

Getting comfortable with these systems is a game-changer for any sewist. Think of thread weight charts as your essential cheat sheet. Here at B-Sew Inn, we rely on them to translate between Tex, Denier, and Wt so we can perfectly match threads to our quilting or embroidery designs. Whether it's picking a bold 30wt for topstitching or a gossamer-fine 100wt for intricate work on a Baby Lock multi-needle machine, understanding the numbers is key. For those who enjoy history, learning about the history of thread measurements can offer even deeper insights.

Your Comprehensive Thread Weight Conversion Chart

Trying to make sense of different thread measurement systems can feel like learning a new language. You've got Wt, Tex, and Denier, and it's not always obvious how they relate. That's exactly why a good conversion chart is one of the most useful tools you can have in your sewing room.

This section is designed to be your go-to "how-to" reference, a cheat sheet you can turn to whenever you're picking out thread for your next design. No more guesswork. Whether you're piecing, quilting, or adding that perfect topstitch, matching the thread weight to the job is key for a beautiful, professional finish.

Quick Reference Conversion Table

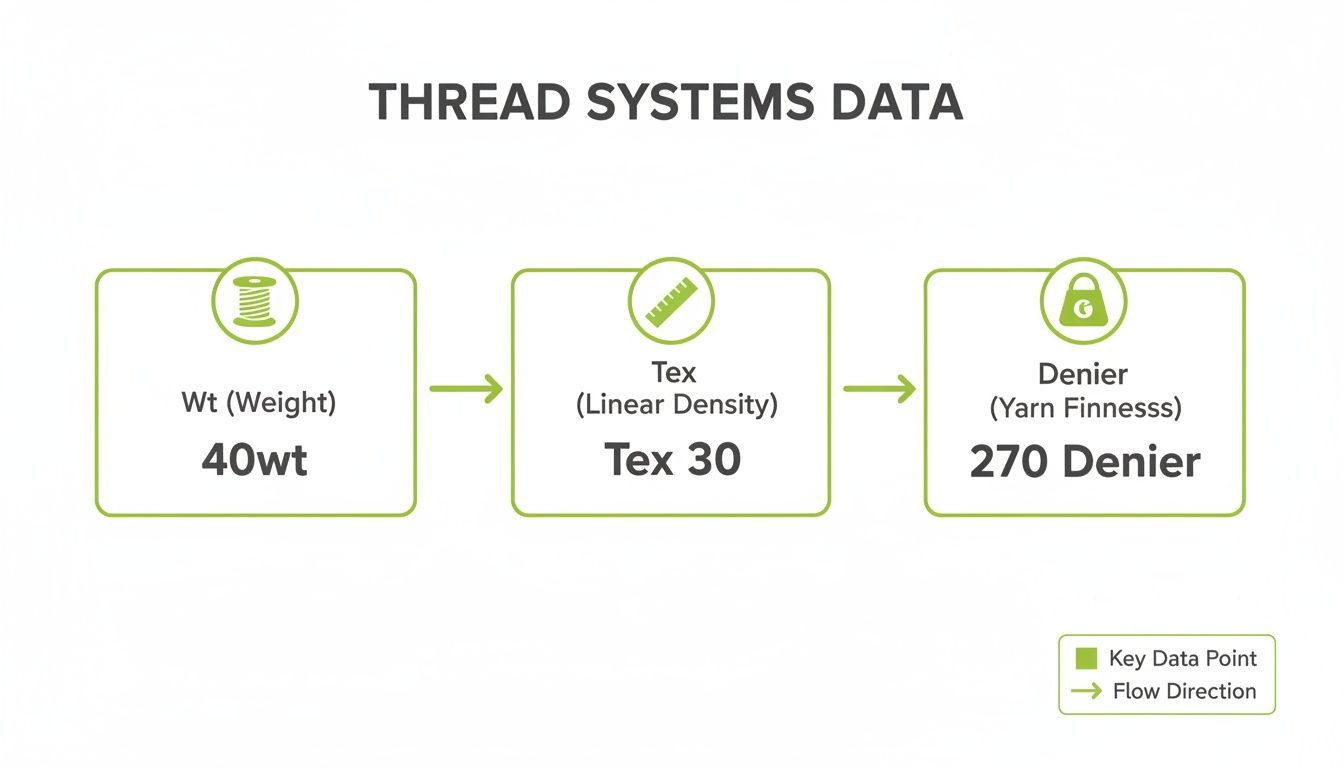

First, let's get a visual on how these systems connect. It helps to see that they're just different ways of measuring the same thing: thread thickness.

As you can see, a standard 40wt thread is the same as a Tex 30 or a 270 Denier. It’s not that one is "better," they're just different scales. Knowing how to translate between them gives you the confidence to pick the right spool for any design you want to create.

Thread Weight Conversion and Usage Chart

To really dig in, here’s a quick-reference table I put together. It lines up the most common thread weights across all three systems and gives you tangible examples of what they’re typically used for, along with a needle size recommendation. Think of it as your project-planning shortcut.

| Weight (Wt) | Tex | Denier (Den) | Common Applications | Recommended Needle Size |

|---|---|---|---|---|

| 12wt | 80-105 | 720-950 | Heavy topstitching, big-stitch hand quilting, sashiko, decorative stitching. | Topstitch 100/16 or 110/18 |

| 30wt | 45-50 | 400-450 | Machine quilting where you want the thread to pop, topstitching, machine embroidery. | Quilting or Topstitch 90/14 |

| 40wt | 30-35 | 270-315 | Excellent all-purpose thread for quilting, construction, and machine embroidery. | Universal or Quilting 80/12 |

| 50wt | 27-30 | 240-270 | The workhorse for piecing, general sewing, garment construction, and machine appliqué. | Universal or Microtex 80/12 |

| 60wt | 20-25 | 180-225 | Great for fine piecing (especially miniatures), detailed embroidery, bobbin thread, appliqué. | Universal or Microtex 70/10 |

| 80wt | 15-18 | 135-160 | English paper piecing, invisible machine appliqué, delicate heirloom sewing, bobbin thread. | Microtex 60/8 or 70/10 |

| 100wt | 10-12 | 90-110 | The finest thread. Perfect for micro-stippling, invisible ditch quilting, and as a bobbin thread. | Microtex 60/8 |

Remember, these are just starting points! The fabric you're using and your personal machine's preference will always play a role. Don't be afraid to experiment to find what works best for your project.

Pro Tip: If you're ever on the fence, a good quality 50wt thread is your best friend. It’s strong enough for piecing but fine enough that it doesn't create bulky seams, making it a true all-star for most quilting projects. For an even deeper dive, be sure to check out our complete sewing thread size guide.

Matching Thread Weight To Your Project

Knowing how to read a thread weight chart is a great start, but the real magic happens when you can confidently pick the perfect thread for the job. It’s what separates good results from great ones. The thread you choose has a huge impact on your project's final look, feel, and durability.

Every sewing machine design has its own go-to thread weights, and getting familiar with them is a game-changer. At B-Sew Inn, we're committed to empowering you with the tools and the know-how, which is why we offer so many online classes and resources. Let's dig into the most common uses for different thread weights.

Thread Selection For Quilting Projects

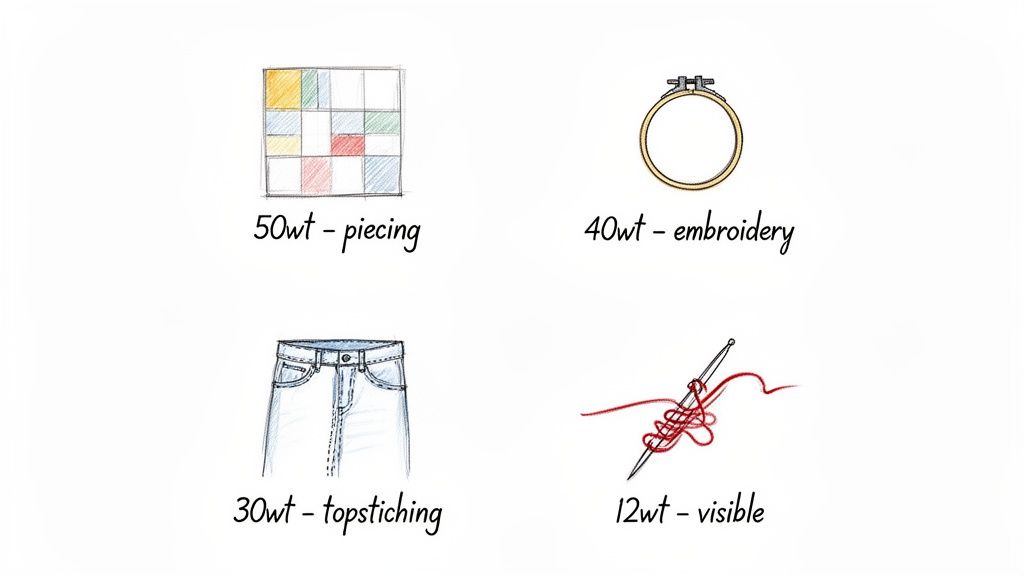

Quilting isn't a one-thread-fits-all kind of craft; different stages call for different threads. When you're piecing blocks for a quilt, you want seams that are strong but lie incredibly flat. The goal is to avoid any extra bulk.

- For Piecing: 50wt thread is the undisputed champion here. It has all the strength you need for durable seams, but it’s fine enough to let your points match up perfectly without creating thick ridges.

- For Decorative Quilting: When you want your stitches to pop and become part of the quilt's visual design, you need to go thicker. A 40wt or even a 30wt thread creates a beautiful, defined stitch that adds amazing texture to your quilt top.

Getting this right means your quilt will not only be stunning but also tough enough to be loved, used, and washed for years to come.

Choosing Thread For Machine Embroidery

Machine embroidery is all about creating beautiful, dense designs that you can replicate perfectly. The right thread needs to provide great coverage without getting chunky, and it has to be strong enough to keep up with the high speeds of modern machines like those from Baby Lock.

The industry standard for most embroidery designs is a 40wt polyester or rayon thread. It gives you that gorgeous sheen and fills in designs smoothly. But for those projects with tiny, intricate details or small lettering, a finer thread is definitely the way to go.

For example: when you're working on a custom monogram design with a Baby Lock multi-needle machine, switching to a 60wt or even an 80wt thread will give you incredibly sharp detail. These finer threads keep the stitches from looking muddy, making sure every part of your design is crisp and clear.

Threads For Garment and General Sewing

For sewing clothes or other general projects, you need a reliable workhorse thread. A 50wt polyester is a fantastic all-purpose choice because it has both strength and a little bit of give—perfect for seams on garments that need to move with you.

Of course, you’ll need to switch it up for heavier fabrics. When you're tackling a design made from denim, canvas, or upholstery, a standard thread just won't cut it. To build seams that can handle real-world stress, you'll want to move up to a stronger 30wt or 40wt thread. Your project will tell you what it needs; learning to listen is all part of the craft.

While a thread weight chart is your map to thickness, the actual fiber your thread is made from is just as crucial. The material—whether it's cotton, polyester, or silk—is what determines its strength, stretch, and finish. Getting this part right means your design will not only look fantastic but also hold up beautifully over time.

Think of it this way: thread weight tells you the size of the tool, but the fiber tells you what that tool is made of. A delicate silk thread and a sturdy polyester thread of the exact same weight are going to perform very differently in your machine.

The Classic Choice: Cotton Thread

Cotton thread is a quilter’s best friend, and for good reason. It has a lovely, soft matte finish that just melts into cotton fabrics, letting your quilt pattern be the star of the show. Since it has almost no stretch, it creates wonderfully crisp, flat seams that are an absolute dream for precision piecing.

That lack of stretch, however, can be a downside for things like garment seams that need to flex and move. And while older cotton threads had a reputation for breaking, modern manufacturing has completely changed the game.

A key innovation was mercerization, a treatment that not only gave cotton a beautiful luster but also boosted its strength by an incredible 30-50%. Then, the arrival of polyester in 1942 and cotton-wrapped polyester in the late 1960s gave sewers a whole new world of options, blending cotton's classic good looks with modern durability.

The Workhorse: Polyester Thread

If there’s one thread that can do it all, it’s polyester. This stuff is the undisputed workhorse of the sewing room. It’s incredibly strong, stands up to UV rays and mildew, and has just a little bit of give. That makes it the go-to choice for garment construction, home decor, and any other project that’s going to see a lot of life and use.

That slight elasticity is exactly what you want in a seam; it allows the stitches to flex along with the fabric, which means you're far less likely to have them pop. You'll also notice polyester comes in a huge range of vibrant colors and often has a bit of a sheen, making it perfect for decorative topstitching and machine embroidery. For a deeper look into various thread materials, you might be interested in our guide on thread types for sewing.

Specialty and Blended Fibers

Once you move past the two main players, you’ll find some other fantastic fibers out there. Silk thread is a personal favorite for delicate fabrics; it's unbelievably fine yet surprisingly strong. It’s the perfect choice for fine silks and for hand-basting when you need temporary stitches that won’t leave a permanent mark on your fabric.

You'll also run into some really clever blends, like cotton-wrapped polyester. This thread gives you the best of both worlds. It has a strong, stretchy polyester core wrapped in a soft cotton exterior. This means it sews and looks like cotton but has the strength of poly, making it a wonderfully versatile pick for both quilting and general sewing. You get all that durability without sacrificing that classic, matte finish.

Pairing Needles and Adjusting Machine Tension

Choosing the right thread is a huge step, but it's only half the battle. To get that perfect, flawless stitch, you have to pair your thread with the correct needle and adjust your machine's tension. Think of them as a team—if one part isn’t working with the others, you'll run into frustrating issues like skipped stitches, shredding, or breakage.

This crucial step ensures the thread can glide smoothly through both the needle's eye and the fabric itself. Getting this combo right is one of those technical skills that can truly elevate your sewing machine designs from good to great.

Matching Needle Size To Thread Weight

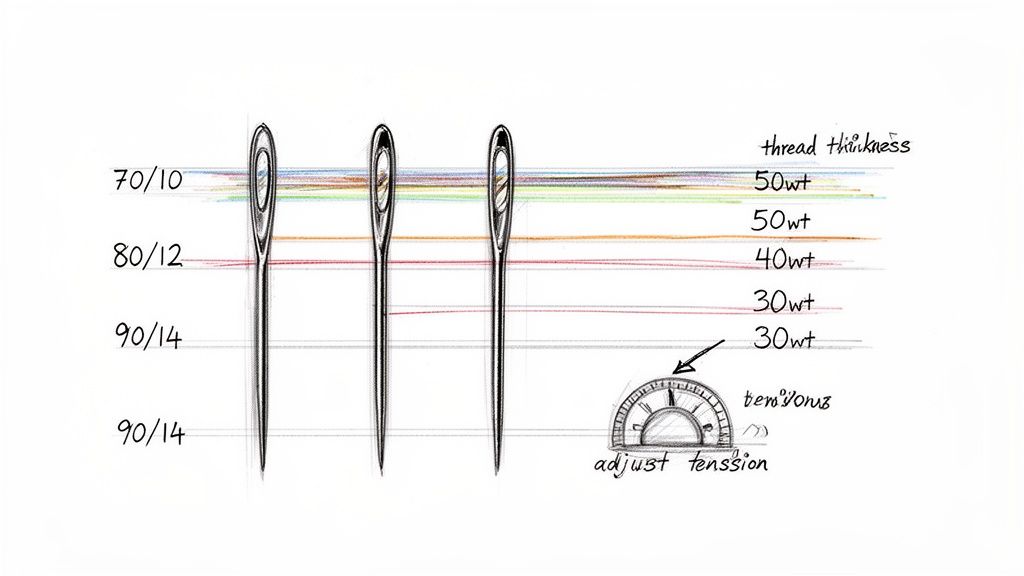

Sewing machine needles have two numbers you’ll see written together, like 80/12. The first number is the European size (ranging from 60 to 110), and the second is the American size (from 8 to 18). For both systems, it's simple: a higher number means a thicker, stronger needle. These beefier needles are designed for heavier threads and fabrics.

The goal here is to punch a hole in the fabric that is just large enough for your thread to pass through without any friction or damage.

Here's a simple "how-to" guide to get you started:

- 100wt or 80wt Thread: Reach for a tiny 60/8 or 70/10 needle. These are perfect for delicate work where you want the needle hole to be practically invisible.

- 60wt or 50wt Thread: A versatile 80/12 needle is the go-to standard. It beautifully handles this popular thread weight for piecing and everyday sewing.

- 40wt Thread: Step up to a slightly larger 90/14 needle. This gives the thicker thread enough room to move without a fight.

- 30wt Thread: For this chunkier quilting and topstitching thread, a 90/14 needle is also a great match, ensuring smooth stitches.

- 12wt Thread: For this very heavy thread, you'll need a large 100/16 or even a 110/18 Topstitching needle. These have a much larger eye to prevent frustrating shredding.

If you want to dive deeper, our guide covering all the different types of sewing machine needles and their specific jobs is a great resource.

Adjusting Your Machine's Tension

Anytime you switch to a different thread weight, you absolutely should test and adjust your machine's tension. It makes sense when you think about it: thicker threads create more pull on the tension discs, while finer threads create less. The goal is always a balanced stitch where the top and bobbin threads meet perfectly between the layers of fabric.

Your best friend here is a quick tension test. Grab a scrap of your project fabric and sew a few inches. If you see little dots of bobbin thread peeking through on top, your top tension is too tight. If you see loops of your top thread on the bottom, it’s too loose.

Make tiny adjustments—usually just one number at a time—and re-test until your stitches look perfect on both sides. This small step prevents big headaches and is the secret to a professional finish every single time.

Troubleshooting Common Thread Issues

Even when you’ve picked the perfect thread weight and needle, you can still run into frustrating issues that bring a design to a screeching halt. We’ve all been there. Problems like your thread shredding, breaking, or creating ugly loops are usually simple to fix, but you have to know what to look for. Think of this as your first-aid checklist to diagnose the problem and get back to sewing.

At B-Sew Inn, we're dedicated to empowering you with skills through our online training and extensive resources, so you always feel supported on your creative journey. We believe that learning to partner with your machine to solve these little hiccups is just as important as having the right tools in the first place.

Diagnosing Thread Shredding and Breaking

When your top thread starts to fray or snap mid-seam, it's a dead giveaway that there's too much friction somewhere along its path. Before you throw in the towel, run through this quick checklist of the usual suspects.

- Needle and Thread Mismatch: Honestly, this is the number one culprit. If the needle's eye is too small for the thread, it will literally shred your thread to bits as you sew. Cross-reference your thread weight chart with your needle size to make sure they’re a happy couple.

- Old or Damaged Needle: A needle might look fine, but a microscopic burr or a dull point can snag and break thread in an instant. As a general rule, you should pop in a fresh needle after every 8-10 hours of sewing. It makes a world of difference.

- Incorrect Threading: It happens to the best of us. Take a deep breath, unthread your machine completely, and start over. Double-check that the thread is seated snugly in every single guide and tension disc. Crucially, make sure your presser foot was up when you threaded the machine—this opens up the tension discs to accept the thread properly.

Solving Puckering Fabric and Looping Stitches

Seeing puckered fabric or a mess of loops on the back of your work is a classic sign of a tension tantrum. Don't worry, the fix is usually pretty straightforward once you know where to look.

A beautifully balanced stitch is what we're all aiming for. When your top and bobbin threads meet perfectly right in the middle of your fabric layers, it’s a beautiful sign that your machine, thread, and needle are all working in harmony to create your design.

To get things back in balance, start by taking a close look at your setup.

- Check Your Thread Weight: Using a thread that’s too heavy for your fabric is a guaranteed recipe for puckering. A beefy 30wt thread, for instance, will easily pull and distort a delicate lawn or voile. Try switching to a finer 50wt or 60wt thread to match your lightweight fabric.

- Adjust Top Tension: If you see loops on the underside of the fabric, your top tension is too loose. Tighten it in small, one-number increments, stitching on a scrap after each adjustment until those loops vanish.

- Rethread the Bobbin: An unevenly wound or improperly inserted bobbin can cause all sorts of tension headaches. Take it out, give it a quick visual inspection to see if it’s wound evenly, and pop it back in, making absolutely sure it's settled correctly in its case.

A Few Common Questions About Thread Weight

Getting the hang of thread weight can feel a bit tricky at first, but once you nail down a few key concepts, you'll be choosing the right thread like a pro. Let's tackle some of the questions I hear most often from fellow sewists.

Think of these "how-to" tips as the key to unlocking the full potential of your sewing machine and getting that perfect, professional finish on your custom designs.

Can I Use The Same Weight Thread In The Bobbin And On Top?

You certainly can, but many experienced quilters and embroiderers will tell you it’s often better not to. My go-to trick is to use a slightly finer thread in the bobbin, something like a 60wt or even an 80wt.

This little change makes a huge difference, especially when you're creating a design with dense quilting or intricate embroidery. A finer bobbin thread reduces the bulk on the back of your project, which helps your quilts lie flatter and makes achieving a perfectly balanced stitch tension so much easier.

What’s The Best All-Purpose Thread For A Beginner?

If you're just starting out, you absolutely cannot go wrong with a 50wt cotton or polyester thread. It's the true workhorse of the sewing world and the perfect all-around choice for a massive range of projects you can create.

A 50wt thread is strong enough for durable seams in quilting and garment making, but it's still fine enough that it won’t add any unwanted bulk. It really is the most reliable, versatile thread you can have in your stash and a fantastic starting point for any new sewist looking to replicate different designs.

Does Thread Weight Matter For Hand Sewing?

Oh, absolutely! Thread weight is just as critical for hand sewing, maybe even more so because it directly affects both the look and the strength of your stitches. The right choice really comes down to what you want your stitches to do.

Here’s how I think about it:

- For Decorative Stitches: When you want your stitches to stand out as part of a design, grab a thicker thread like a 12wt or 30wt. It’s perfect for creating that beautiful, bold look in big-stitch quilting or hand embroidery.

- For Functional Seams: If you're piecing by hand or sewing a seam that needs to be strong but not seen, a finer 50wt thread is your best bet. It sinks into the fabric and creates a nearly invisible, durable seam.

Here at B-Sew Inn, our goal is to empower you at every step of your creative journey. Whether you need the right machine, the perfect supplies, or a little extra training from our online classes, we're here to help you bring every vision to life. You can explore everything we have to offer at B-Sew Inn's official website.