Welcome to the wonderfully tactile world of mechanical sewing. If you've ever felt overwhelmed by computerized models with their glowing screens and endless menus, a mechanical sewing machine is a breath of fresh air. It's all about direct, hands-on control, with sturdy knobs and dials that give you a real feel for what you're doing.

This guide will serve as a comprehensive how-to for mastering your machine, showcasing tangible examples that you can replicate to build your skills. You’ll quickly see why this classic design is still a beloved favorite for so many crafters.

Why Choose a Mechanical Sewing Machine

Picking out a new sewing machine is one of the most exciting steps you can take in your creative journey. With a mechanical machine, you get a direct, satisfying connection to your project. I like to think of it like driving a manual car versus an automatic—you’re completely in tune with the machine’s performance, feeling every stitch and adjustment right through your fingertips. It’s that hands-on control that draws so many sewists to these reliable workhorses.

Here at B-Sew Inn, our commitment is to empower crafters like you. We achieve this through our custom sewing machine designs and by helping you truly understand your most important tool. The beauty of a mechanical model is its straightforward design. There are no complex electronics or digital screens to navigate. Instead, it operates with a system of gears, levers, and belts working in perfect harmony. This simplicity is its greatest strength, making it incredibly durable and often a much more affordable choice for beginners and seasoned pros alike.

The Appeal of Simplicity and Durability

The core benefits of a mechanical sewing machine are pretty clear. They are built to last, often featuring solid metal frames that can handle years of heavy use. This makes them absolute champs for sewing through tough stuff like denim, canvas, or multiple layers of fabric without even flinching. Imagine creating a sturdy canvas tote bag or hemming a pair of jeans—a mechanical machine powers through those thick seams with ease.

Their straightforward guts also mean there are fewer electronic parts that can fail, which leads to easier maintenance and troubleshooting down the road. For a lot of people, this durability translates directly into creative freedom. When you're not worried about fidgeting with complex settings or potential digital glitches, you can focus completely on your craft. It’s this rock-solid reliability that makes so many experienced sewists (myself included!) keep a mechanical machine as a trusty backup.

A mechanical machine really encourages you to learn the fundamentals of sewing in a deep, intuitive way. Every turn of a dial teaches you something new about tension, stitch length, and how the machine interacts with your fabric. You're not just pushing buttons; you're building a solid foundation of skill and confidence.

Who Benefits Most from This Classic Design

A mechanical sewing machine is an excellent choice for a surprisingly wide range of people. It’s a particularly great fit for:

- Beginners: The simple controls and lack of intimidating menus make it the perfect machine to learn on. You'll build good habits from day one while creating simple projects like pillowcases or aprons.

- Crafters on a Budget: They generally come with a lower price tag without sacrificing stitch quality or power.

- Sewists Needing a Workhorse: If your projects involve heavy-duty materials for things like upholstery or bag making, the robust build of a mechanical model is an absolute must-have.

Think of this guide as your starting point. At B-Sew Inn, we’re here to support you long after you bring your machine home. We offer extensive resources, including online classes and dedicated training, designed to help you master your new machine and bring every creative vision to life.

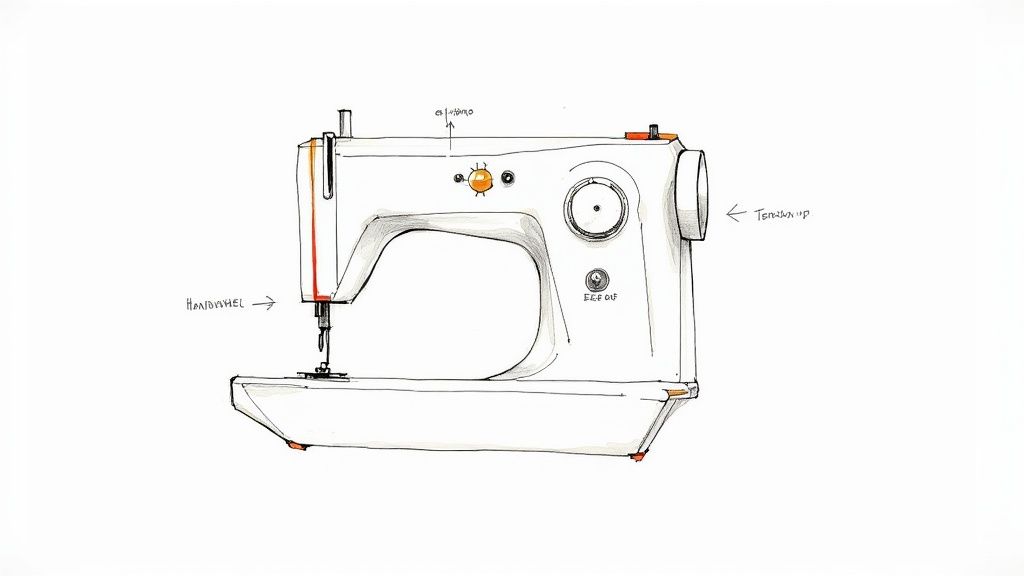

Understanding Your Machine's Core Components

Getting to know a mechanical sewing machine can feel a little like learning a new language. But don't worry, every part has a simple, specific job. Instead of a bunch of electronics, these machines run on a beautifully coordinated system of gears, levers, and dials all working together. Getting a handle on these core components is the first step to feeling truly confident behind the needle.

Think of it this way: if your machine is a car, the handwheel is your manual engine starter. It’s that big dial on the side. A quick turn towards you manually lowers and raises the needle, giving you pinpoint control when you're starting a seam or need to pivot at a corner. It's the most direct physical connection you have to the machine's inner workings.

This hands-on approach is what builds a solid sewing foundation. Once you know what each part does, you move from just following instructions to truly understanding the craft.

The Brains and Brawn of the Operation

Every mechanical machine has a set of main controls that decide what your stitches look and feel like. These are the parts you’ll be touching the most during any project.

The stitch selection dial is your creative command center. A simple turn clicks you through all the available stitch patterns—maybe a straight stitch, a zigzag, or a buttonhole setting. There are no screens here, just a satisfying, tactile dial that shows you exactly what you’ve chosen.

Right next to it, you'll usually find the stitch length and stitch width dials. These are for fine-tuning your chosen stitch. A longer stitch length is perfect for temporary basting or decorative topstitching, while a shorter length makes for a much stronger, more secure seam. The width dial, naturally, adjusts how wide a stitch like a zigzag will be.

By mastering these manual controls, you gain an intuitive feel for how each little adjustment impacts your final stitch. This is invaluable knowledge. It empowers you to troubleshoot problems and make creative choices on the fly, without ever needing an automatic setting to do the thinking for you.

These simple, direct controls are a huge reason why so many sewists fall in love with their mechanical machines. You are always in full command.

Managing Thread and Fabric Movement

Perfect stitches really boil down to two things: balanced thread tension and steady fabric movement. Several key parts work together to make this happen without a hitch.

The tension dial is one of the most important parts to get familiar with. It controls how tightly the upper thread is being pulled. If your stitches look loopy on the bottom of the fabric, your top tension is probably too loose. If they're loopy on top, it's too tight. Getting that dial just right ensures your stitches lock perfectly between the fabric layers.

Underneath your fabric, the feed dogs act like a tiny conveyor belt. These little metal teeth grip the material from below and pull it through the machine at a steady pace, moving in perfect time with the needle. Their precise movement is what guarantees every stitch is the same length.

Finally, the presser foot holds the fabric firmly down against those feed dogs. You lower it using a lever on the back of the machine, and it provides the pressure needed to keep everything from shifting. You can even swap out presser feet for different jobs, like putting in zippers or sewing on buttons.

Here’s a quick-reference guide to help you remember what’s what.

Key Components and Their Functions

| Component | Primary Function | What It Controls |

|---|---|---|

| Handwheel | Manually operates the needle | Starting, stopping, and precise needle placement |

| Stitch Selection Dial | Chooses the type of stitch | The pattern of the stitch (e.g., straight, zigzag) |

| Tension Dial | Adjusts the tightness of the upper thread | The balance and appearance of the stitches |

| Feed Dogs | Pulls the fabric through the machine | The consistency and length of each stitch |

| Presser Foot | Holds the fabric down securely | Fabric stability and guidance during sewing |

Getting comfortable with these parts will completely change your sewing experience. For a deeper dive into the first steps of using your machine, you can learn more about sewing machine basics for beginners in our detailed guide.

At B-Sew Inn, we're here to help you through every step, from understanding your machine's anatomy to finishing amazing projects with our extensive resources and online classes.

How to Choose the Right Mechanical Sewing Machine

Shopping for a new mechanical sewing machine is a little like finding a new creative partner. You're not just looking for the model with the longest list of features; you're looking for the right features for the projects you dream of making. Think of it as an investment in a tool that will be by your side for years to come.

This how-to guide will help you tune out the noise and focus on what really counts. We'll walk through the key things to look for so you can pick a machine that feels like it was made just for you, ready to bring your ideas off the cutting mat and into the real world.

Assessing Build Quality and Durability

The real heart and soul of any great mechanical machine is its frame. This is the internal skeleton that keeps every moving part humming along in perfect alignment, giving you that stability you need for gorgeous, consistent stitches.

You’ll mostly see two kinds of frames: metal and plastic. A machine built with a heavy-duty metal frame is the undisputed champ when it comes to durability. It keeps the machine steady, cuts down on vibrations when you're sewing fast, and has the muscle to power through tough stuff like denim, canvas, or even leather without skipping a beat. If you're planning on heavy-duty projects or just want a machine that’s built to last a lifetime, a metal frame is a fantastic choice.

On the other hand, plastic frames make a machine way lighter and easier to carry around. This is a huge plus if you're tight on space or want to take your machine to classes. While they might not have the raw power of their metal cousins, a well-made plastic frame is more than up to the task for everyday sewing and a whole range of fabrics.

Evaluating Essential Stitch Options

It’s so easy to get wowed by a machine that promises hundreds of stitches, but with a mechanical machine, quality absolutely beats quantity. The truth is, you can complete the vast majority of projects with just a handful of core stitches.

Instead of counting the options, look for a machine that nails these basics:

- Straight Stitch: This is your bread and butter, used for pretty much everything from seams to topstitching. You want a machine that lays down a perfectly straight, even, and balanced stitch every single time.

- Zigzag Stitch: This one is incredibly versatile. You'll use it for finishing raw edges to keep them from fraying, sewing stretchy knit fabrics, and even for simple decorative touches.

- Buttonhole Stitch: For anyone who wants to make clothes, a reliable buttonhole function is a non-negotiable. Whether it's a one-step or four-step process, it saves a ton of time and makes your garments look polished and professional.

- Blind Hem Stitch: This is the secret to hemming pants and skirts with a finish that's nearly invisible from the outside.

Beyond these four, you might want a specific stitch that fits your hobbies, like a stretch stitch for knits or a simple decorative stitch to add a bit of flair.

The true magic of a mechanical sewing machine isn’t in a massive stitch library, but in its power to do the fundamental things perfectly. A machine that delivers a flawless straight stitch is way more valuable than one with 100 messy decorative options.

Considering Motor Power and Fabric Handling

The motor is the engine of your machine. It dictates how consistently you can sew and whether you can tackle more demanding fabrics. A stronger motor gives you more piercing power—that’s the force the needle uses to punch through the fabric. This is a huge deal when you're sewing through multiple layers for quilting or bag making.

Working right alongside the motor are the feed dogs. Those are the little metal teeth under your presser foot that grip the fabric and pull it through the machine. A good, strong feed dog system means your fabric moves along smoothly and evenly. It prevents puckering on fine silks and keeps things moving steadily on thick upholstery fabric.

It's amazing to think how far we've come. The first practical mechanical sewing machines, back around 1830, could churn out about 200 stitches per minute! It was a massive leap from sewing by hand. By 1860, over 110,000 machines were being made in the US alone, which just shows how quickly this tool changed everything. You can read more about this cool history in the evolution of sewing machines from Dainessewing.com.

Here at B-Sew Inn, we love helping people navigate all these choices. Our team can walk you through different models, explain what all the features really mean for your sewing, and help you find a machine that not only fits what you need today but will grow with you as your skills blossom.

Comparing Mechanical and Computerized Machines

Deciding between a mechanical and a computerized sewing machine really comes down to how you like to work. Do you love the hands-on, tactile feel of turning knobs and dials? Or do you prefer the set-it-and-forget-it precision of a digital screen? There’s no right or wrong answer—just what feels best for your creative flow. Let's break down the key differences to help you find your perfect match.

A mechanical sewing machine is the classic workhorse. Think of it like a manual transmission car—it’s all gears and levers, and you’re in complete control. Every single adjustment, from picking your stitch to tweaking the tension, is done by turning a physical dial. For a lot of us, that direct connection to the machine is a huge part of the joy of sewing.

On the other hand, a computerized machine has a small computer inside that does a lot of the heavy lifting. You'll use an LCD screen to pick your stitches, and the machine can automatically set the perfect length and width, stitch flawless buttonholes, and even snip your threads for you. It’s all about convenience and having a massive library of stitches just a button-push away.

Operation and User Experience

The biggest difference is how you actually use the machine. With a mechanical model, you are the pilot. You feel the machine respond as you make adjustments, giving you a really intuitive, hands-on experience. That simplicity is its greatest strength; there are no menus to get lost in, which makes it incredibly welcoming for beginners.

Computerized machines offer a more guided experience. They’ll often suggest the right presser foot for a stitch you’ve selected and can even remember your favorite settings. This automation is a huge time-saver, especially when you’re working on complex projects with lots of decorative stitches. But for those who love being in the driver's seat, that electronic assistance can feel a bit less direct.

The choice really says a lot about your personality as a sewer. Do you want to be the conductor, guiding every little detail yourself? Or would you rather have a skilled assistant handle the technical stuff so you can focus on the big picture?

Here at B-Sew Inn, we want you to have the tools that bring your vision to life. That’s why we back you up with everything from online classes to one-on-one training, so you can master whichever machine you choose.

Features and Capabilities

This is where the two types really start to look different. A mechanical sewing machine gives you a solid set of the essentials: straight stitch, zigzag, blind hem, and a basic buttonhole function. While that might not sound like a lot, these core stitches will cover over 90% of all your sewing projects. Plus, their beefy all-metal insides often give them incredible piercing power for tough materials like denim or canvas.

Computerized machines are where you find all the bells and whistles. They can come loaded with hundreds of stitch options, from beautiful decorative patterns to multiple fonts for monogramming. The automated features are their main draw:

- One-Step Buttonholes: Creates perfectly matched, uniform buttonholes every single time.

- Automatic Needle Threader: A real lifesaver for your eyes and your patience!

- Speed Control Slider: Lets you set a max speed, which is fantastic for tricky curves or teaching kids.

- Needle Up/Down Function: A must-have for perfect pivots at corners.

To help you visualize the trade-offs, here’s a quick side-by-side look.

Mechanical vs. Computerized Sewing Machines

| Feature | Mechanical Sewing Machine | Computerized Sewing Machine |

|---|---|---|

| User Control | Manual dials and levers; very tactile | Digital screen and buttons; automated |

| Stitch Selection | Limited to essential utility stitches | Potentially hundreds of stitches |

| Best For | Beginners, heavy-duty sewing, simplicity | All skill levels, decorative work, convenience |

| Maintenance | Simpler to maintain and repair | Can be more complex and costly to service |

| Price Point | Generally more affordable | Wider price range, from entry-level to high-end |

At the end of the day, both types get the job done beautifully. The right one is simply the one that makes you want to sew.

For a deeper dive, you can explore the differences between computerized and mechanical sewing machines in our comprehensive article.

Maintenance and Long-Term Value

When it comes to durability and easy repairs, mechanical models are tough to beat. With fewer electronic parts, there’s simply less that can go wrong. Maintenance is usually pretty straightforward—a good cleaning and regular oiling will keep them humming along for decades. And if something does need fixing, it’s often a simpler and less expensive job.

Computerized machines, with their circuit boards and screens, can be more complicated and costly to fix if an electronic part gives out. That said, they are built to very high standards and are incredibly reliable when cared for properly. Ultimately, the best machine is one that inspires you to sit down and create, and knowing these key differences ensures you’ll invest in a sewing partner you’ll love for years.

Mastering Setup and Routine Maintenance

A mechanical sewing machine is built to last, but like any finely-tuned tool, it needs a little TLC to perform its best. Getting the hang of a few simple setup and maintenance habits is really the secret to smooth, headache-free sewing. These quick routines will keep your machine humming along, stop common frustrations like skipped stitches before they start, and seriously extend its life.

Think of it as a quick chat with your machine—just a way to keep it happy and ready for whatever project you throw at it next. It doesn't take much time, but the payoff in performance is huge. Plus, there's a certain satisfaction in knowing how to care for your own tools.

The Three Pillars of a Perfect Setup

Before your needle even touches the fabric, getting the setup right can be the difference between a fun afternoon and a frustrating one. Honestly, nailing these three little tasks will solve most common sewing problems before they even have a chance to begin.

- Winding a Perfect Bobbin: I can't tell you how many stitch problems trace back to a wonky bobbin. You're aiming for one that's wound evenly and firmly—not so loose that the thread is loopy, but not so tight that it's stretched. A good bobbin should look as tidy as a brand-new spool of thread.

- Threading with Confidence: Every mechanical machine has its own specific thread path. Just follow the numbered guides on your machine exactly. This ensures the thread sits perfectly in the tension discs and the take-up lever, which is critical for good stitches.

- Changing the Needle Often: This is the single most important habit for great-looking stitches. A dull or bent needle is the culprit behind skipped stitches, pulled threads, and can even damage your beautiful fabric. A good rule of thumb? Start every new project with a fresh needle.

This process flow shows the key decisions when selecting a machine, whether you're leaning toward the hands-on control of a mechanical model or the automated features of a computerized one.

As the visual shows, both paths get you to the same place—a reliable sewing machine! The journey is just defined by whether you prefer direct, hands-on control or digital convenience.

Your Simple Maintenance Checklist

Keeping your mechanical machine in tip-top shape is way easier than you might think. A few minutes of care after every couple of projects will keep it running like it's brand new for years and years.

The number one enemy of a smooth-running machine is lint buildup. All that fuzz from fabric and thread can get packed into the tightest spaces, soaking up oil and causing parts to grind. Grab a little brush and regularly clear out two key spots:

- The Bobbin Area: Pop out the bobbin case and gently brush out any lint you can see.

- Under the Needle Plate: Unscrew and remove the needle plate to get to the feed dogs—lint absolutely loves to hide in there.

A clean machine is a happy machine. Think of de-linting as the most important part of your routine. Just five minutes of cleaning can save you hours of trying to figure out tension problems later.

Lastly, a drop of oil keeps everything moving gracefully. Your machine's manual will point you to the exact spots that need a single drop of high-quality sewing machine oil. Just be careful not to overdo it; any excess can end up on your fabric.

For a complete walkthrough, check out our guide on how to properly clean your sewing machine. Here at B-Sew Inn, we want you to feel totally confident taking care of your machine.

Your Sewing Journey Starts Here with B-Sew Inn

Picking out the right mechanical sewing machine is a huge step, but honestly, that’s just the beginning. The real magic happens when you’ve got the right people in your corner, cheering you on. And that's exactly where your journey with B-Sew Inn kicks off. We’re not just here to sell you a machine; we’re here to empower you with the tools, know-how, and community to really thrive.

We want you to bring those amazing ideas in your head to life!

Our commitment to empowering crafters shines through our custom sewing machine designs, which serve as tangible examples for projects you can replicate. We pour our experience into creating these how-to guides so that every machine we recommend is a tool you’ll genuinely love using. But like I said, the machine is only the start of our partnership.

More Than a Machine—A Community of Support

When you get your machine from B-Sew Inn, you’re plugging into a whole support system built for your success. We know from experience that nothing builds confidence like hands-on learning, which is why we offer extensive resources including a full schedule of online classes. These sessions are perfect whether you're trying to master a tricky new technique or just learning the basics from scratch.

Need something a bit more focused? We also offer personalized, one-on-one training sessions. Our experts will sit down with you and answer your specific questions, helping you get comfortable with every knob, dial, and lever on your new machine. Our goal is to make you feel empowered, not overwhelmed.

At B-Sew Inn, you're not just buying a product—you're joining a community that’s genuinely dedicated to helping you create. We believe that having access to great education is just as important as the machine itself.

Resources to Fuel Your Creativity

We want everyone to have a chance to own a quality machine that will last. Our flexible financing options make it possible to invest in a durable, reliable machine without breaking the bank. Once you’ve found the one, our dependable shipping service will get it safely to your doorstep, so you can start creating right away.

And beyond that first purchase, you become part of a network that’s packed with resources. From our huge library of online tutorials to our supportive community of fellow sewists, everything is here to help you succeed. When you partner with us, you’ll always have a place to turn for inspiration, guidance, and a little encouragement along the way.

Got Questions? We've Got Answers

Once you start spending time with your mechanical sewing machine, you're bound to have a few questions pop up. It happens to everyone! Here are a few of the most common ones we hear in the shop, with answers to help you sew with a little more confidence.

Can a Mechanical Machine Handle Quilting?

You bet it can! While it might not have the massive throat space of a dedicated long-arm quilting machine, a good, sturdy mechanical model is a dream for piecing quilt tops. That powerful motor and consistent stitch are exactly what you need to punch through multiple layers of cotton and batting.

The real secret weapon here is a walking foot. It’s an accessory that grips and feeds the top and bottom layers of your quilt sandwich through the machine evenly—a total game-changer for any quilter. Pair that with the reliable muscle of a mechanical sewing machine, and you’ll be turning out beautiful quilts in no time.

What's the Most Common Problem I'll Run Into?

Honestly? Nine times out of ten, when your stitches start skipping or your thread turns into a tangled mess, the culprit is the needle. A dull, bent, or wrong-sized needle is the #1 cause of most sewing headaches. It’s such a simple thing, but it’s so often overlooked.

Before you start messing with the tension or re-threading the machine for the fifth time, just stop. Swap out the needle for a fresh one. This one little step solves an estimated 80% of stitch-related problems and will save you a mountain of frustration.

And remember, use the right needle for the job! A universal needle is fine for most woven fabrics, but you'll want a ballpoint for knits or a tough denim needle for those heavy-duty projects.

How Do I Know When It’s Time to Upgrade?

You’ll get a feeling. It's that moment when your creative ideas start getting bigger than what your machine can easily handle. It usually shows up in a few ways:

- You're craving more stitches: You start wishing you had a few decorative stitches for a special project or specific stretch stitches that your current model just doesn’t have.

- You're tired of the manual work: Doing buttonholes one step at a time or squinting to thread the needle starts to feel like a chore, and you find yourself daydreaming about a machine that does it for you.

- Your projects are getting bigger: You’re wrestling a big quilt or a set of curtains through the machine and constantly wishing you had more room to the right of the needle.

When you hit this point, it doesn’t mean your mechanical machine has let you down—it means you’ve grown as a sewist! That's where we come in. At B-Sew Inn, we love helping people take that next step and find a machine that’s ready for their next creative adventure.

Ready to jump into your sewing journey or find the perfect machine to grow with? B-Sew Inn has a hand-picked selection of quality machines, real-world expert advice, and the classes you need to succeed. Come see what we have in store and join a community that’s as passionate about creating as you are at https://www.bsewinn.com.