If you’ve ever tried to push thick fabric like denim or leather through a regular sewing machine, you know the frustration. Skipped stitches, bent needles, maybe even a worrying grinding sound from the motor. It’s not you, it’s the machine.

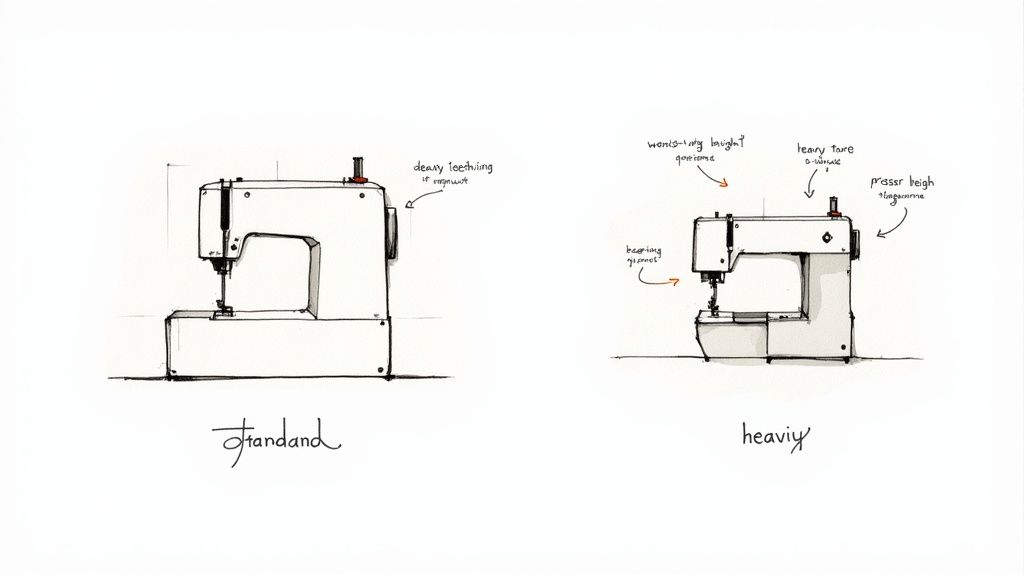

To really conquer heavy materials, you need a machine built for the job. We're not just talking about a fancy brand name; we're talking about the guts of the machine. The best sewing machine for thick material boils down to three core things: a powerful motor to punch through dense layers, a high presser foot clearance to actually fit that bulky project underneath, and a robust all-metal frame to keep everything stable and vibration-free.

Why Your Machine Choice Matters for Heavy Fabrics

Trying to sew a heavy canvas tote on a machine designed for quilting cotton is like trying to chop down an oak tree with a butter knife. You might make a dent, but you're going to have a bad time and ruin your butter knife in the process.

Standard domestic machines are fantastic for everyday fabrics, but their internal gears are often plastic. That’s perfectly fine for cotton and polyester, but they'll strain, flex, and can even break when forced to ram a needle through tough materials. This is where a heavy-duty machine earns its keep. It's engineered from the ground up for power and durability.

Here's a quick comparison to put things in perspective.

Key Features for Sewing Thick Materials at a Glance

This table breaks down the essential differences between a standard machine and one that’s truly ready for heavy-duty work. Think of it as your cheat sheet for spotting a powerhouse.

| Feature | Standard Domestic Machine | Heavy-Duty Machine for Thick Material |

|---|---|---|

| Motor | Lower wattage, designed for lightweight fabrics like cotton. | Higher wattage or high-torque motor for consistent needle penetration. |

| Frame Construction | Often a mix of plastic and lightweight metal. | All-metal frame for stability, reduced vibration, and long-term durability. |

| Presser Foot Lift | Standard height, may struggle with more than 2-3 layers of denim. | Extra-high lift to easily accommodate multiple layers of thick material. |

| Sewing Speed | Moderate speed, may slow down on thick seams. | Higher stitches per minute (SPM) without losing power. |

| Internal Gears | Frequently made of plastic. | Primarily metal gears to handle higher torque and resistance. |

| Needle Compatibility | Best with universal needles up to size 16. | Can handle larger and specialized needles (size 18+, leather, denim). |

Seeing the specs side-by-side makes it clear: a heavy-duty machine isn't just a beefed-up version of a standard one. It’s a completely different class of tool designed for a much tougher job.

Power, Clearance, and Frame: The Big Three

When you're looking at machines, these three features are non-negotiable. They work together as a system to give you the performance you need.

As the flowchart shows, it all starts with power. But without the clearance to fit your project and a strong frame to support the whole operation, that power is wasted.

Mechanical vs. Computerized Powerhouses

Once you start looking, you’ll see heavy-duty machines generally fall into two camps: mechanical and computerized. Mechanical workhorses are the old-school favorites, loved for their raw strength and no-fuss operation. They just work.

Computerized models bring precision and convenience to the table. Think automated features, perfect stitch consistency, and a wider array of stitch options, which can be a game-changer for detailed work on tough fabrics. Digging into the specifics of different upholstery materials can really help you zero in on which features you’ll actually use.

"A machine's ability to handle thick fabric is a direct result of its motor strength and frame integrity. Without a solid metal frame to absorb vibration and a motor with enough torque, even the most advanced features are useless against heavy materials."

If you’re stuck on which path to take, our guide comparing computerized sewing machines vs mechanical models is a great place to start. Getting this choice right is the first real step to matching your creative ideas with a machine that can actually bring them to life.

Why Your Regular Sewing Machine Hates Heavy Fabrics

Ever tried to hem a pair of jeans, only to have your trusty sewing machine throw a fit? You hear a clunk, the needle snaps, and the stitches look like a jagged mess. We’ve all been there. It’s a frustrating experience, but here’s the secret: it’s not you, it’s the machine. Standard sewing machines are fantastic for quilting cottons and flowy rayons, but they just aren't built for a brawl with thick, dense fabrics.

Think of it like trying to tow a boat with a small city car. Sure, the engine is perfect for zipping around town, but the moment you hook up that heavy load, it’s going to strain, sputter, and fail. A standard sewing machine’s motor is that city car—perfectly capable for its intended job, but completely out of its league against the resistance of denim, canvas, or leather.

A proper sewing machine for thick material isn't just a beefed-up version of a regular one. It’s engineered from the ground up for power and durability.

It All Starts With the Motor: Power and Torque

The motor is the heart of your machine. A standard motor is built to glide through lightweight fabrics with ease. But when you introduce something like thick canvas, the needle has to physically force its way through dense, tightly woven fibers. That takes a serious amount of muscle.

A regular motor just can’t keep up. It will start to strain and hesitate, which is the root cause of all those classic sewing headaches:

- Skipped Stitches: The motor doesn't have enough oomph to punch the needle through cleanly, so the hook underneath misses the thread loop entirely.

- Bent and Broken Needles: As the needle hits the dense fabric, it can flex or deflect just enough to hit the metal throat plate instead of passing through the hole. Snap!

- Wobbly Stitches: The machine struggles to maintain a consistent speed, leading to uneven stitch lengths and a sloppy, unprofessional finish.

A heavy-duty motor, on the other hand, delivers high torque. Think of torque as the raw rotational force that drives the needle through tough layers without even breaking a sweat. That consistent power guarantees that every single stitch is formed perfectly, no matter how thick the material. It’s the number one reason a dedicated sewing machine for thick material feels like a completely different (and better) world.

At bsewinn.com, we're big believers in matching your machine's power to your creative ambitions. Our custom machine designs and hand-picked selections are all about providing the torque you need, and our online classes can show you exactly how to put that power to good use on tangible projects you can replicate at home.

Why a Full Metal Frame Isn't Just a "Nice-to-Have"

If the motor is the heart, the frame is the skeleton. Many beginner-friendly machines use a lot of plastic in their construction to keep costs and weight down. That's perfectly fine for sewing pillowcases, but it becomes a huge weak point when you're tackling upholstery or multiple layers of denim.

All that force from a powerful motor punching through tough fabric creates a ton of vibration. A machine with a plastic or hybrid frame will literally flex and shake under the stress. This not only makes it nearly impossible to guide your fabric straight but also causes premature wear and tear on all the delicate parts inside.

A full, heavy-duty metal frame acts as a rock-solid foundation, absorbing those vibrations. It keeps the machine stable, even when you're sewing fast, delivering precise stitches and protecting the finely-tuned timing of the internal mechanisms. It’s this internal fortitude that gives a heavy-duty machine its legendary longevity and reliability. For professionals, industrial sewing machines are the gold standard here, engineered with reinforced frames and beastly motors to chew through materials that would destroy a domestic machine. If you're curious about the pro-level gear, you can get more insights on the industrial sewing machine market at gminsights.com.

Ultimately, choosing a machine with a solid metal frame is an investment in your sewing. It gives you the durability and precision to create with confidence, project after project.

Finding the Right Type of Heavy-Duty Machine

Okay, so you've seen why your standard machine throws a fit when you feed it a thick denim seam. What's the next step? It’s time to explore the machines that are actually built for the job. Choosing the right sewing machine for thick material isn't about finding one magical machine that does everything; it's about matching the tool to your projects.

Think of it like this: you wouldn't use a sports car to haul lumber. You'd grab a rugged pickup truck. For a family road trip with all the latest tech, you’d want an SUV. And for a delivery business, you’d need a powerful commercial van. It’s the same idea with sewing machines.

We can break down these powerhouse machines into three main camps: heavy-duty mechanical, heavy-duty computerized, and semi-industrial. Each brings a different mix of power, features, and control to the table, making them perfect for different types of sewists and projects.

The Workhorse: Heavy-Duty Mechanical Machines

The heavy-duty mechanical machine is the trusty pickup truck of the sewing world. It’s built to do one thing exceptionally well: deliver raw, unfiltered power without any fuss. These machines are all about straightforward, rugged construction.

With a full metal frame and a beefy motor, a mechanical model plows through tough jobs. I'm talking about hemming stacks of heavy denim jeans or building a canvas tote bag that will last for years. All the controls are manual dials and levers, which is something a lot of us love for its simplicity. You just turn a knob to pick your stitch and another to set the length. No screens, no menus—just pure, intuitive sewing that's less likely to run into electronic glitches.

- Best for: Sewists who just need pure muscle for direct projects like denim repair, simple bag making, and basic upholstery.

- Example Project: Imagine you're making a set of custom canvas workshop aprons. A mechanical beast will punch through the thick canvas and webbing straps without skipping a beat, letting you focus on solid construction instead of navigating a computer screen.

The Precision Powerhouse: Heavy-Duty Computerized Machines

If a mechanical machine is the pickup truck, then a heavy-duty computerized model is a high-performance SUV. It gives you the powerful frame and motor you need for tough terrain but adds all the smart features and precision of modern tech.

These machines come loaded with a much wider variety of stitches—decorative ones, perfect buttonholes, even lettering—all selected on an LCD screen. But their real superpower is consistency. A computerized machine delivers a perfect stitch every single time. It handles tension adjustments for you and often includes features like a needle up/down button, which is a lifesaver when you need to pivot perfectly on a thick corner. This level of precision is gold when you're working on something that needs to be both strong and beautiful, like reupholstering a vintage chair or tailoring a structured wool coat.

Here at bsewinn.com, we're all about empowering you to find the perfect machine for your vision. Whether you need a simple mechanical workhorse or a feature-packed computerized model, our goal is to help you master it. Our extensive online resources, from training videos to detailed project guides, are designed to get you sewing your most ambitious projects with confidence.

The Production Beast: Semi-Industrial Machines

Ready to level up? Let's talk about semi-industrial machines, often called "high-speed" machines. This is the commercial van of the sewing world—built for speed, endurance, and handling serious volume. It's the perfect bridge between a domestic heavy-duty and a full-blown factory machine.

Most of these machines specialize in one thing: an incredibly fast, flawless straight stitch. They can hit speeds of up to 1,500 stitches per minute (SPM) or more and are built to run for hours on end without breaking a sweat. This makes them the go-to choice for anyone launching a small business or tackling massive projects. If you’re opening an Etsy shop for handmade leather wallets or belts, a semi-industrial machine gives you the professional-grade stitches and efficiency to actually scale up production. Its ability to handle thicker threads and tough materials day in and day out is just on another level.

The demand for machines that can handle these dense materials isn't just something we're seeing in our shops; it's a market-wide trend. Industry analysis points to a growing category for extra-heavy-weight sewing machines for industries like footwear and heavy-duty workwear. This sector is expected to expand, especially as manufacturing grows. You can dig into more of the data on the industrial sewing machine market on alliedmarketresearch.com. This really highlights why investing in a machine with some industrial DNA is a smart move for serious, long-term crafting. When you match your machine to your projects, you're not just buying a tool—you're investing in the future of your craft.

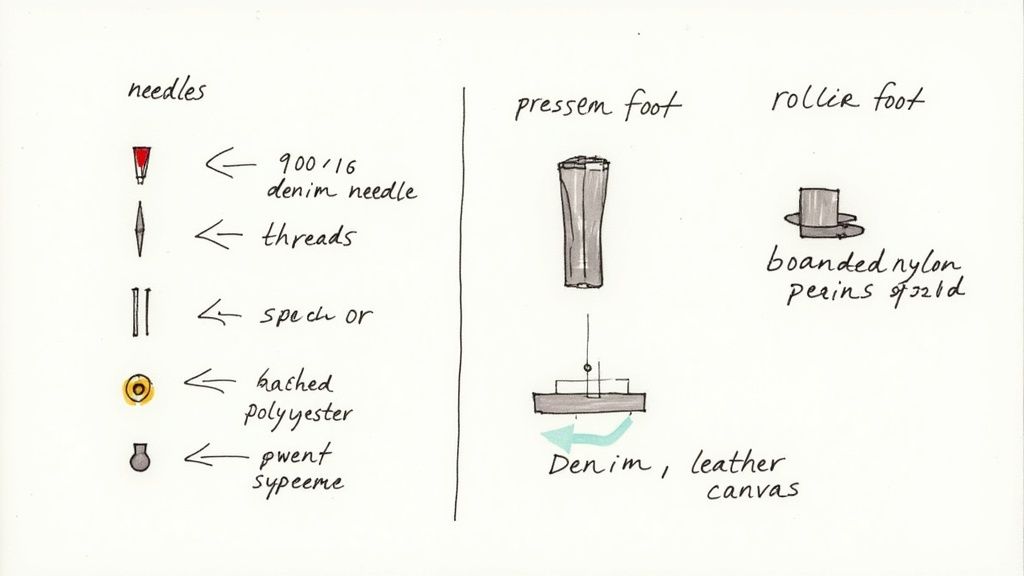

Essential Needles, Thread, and Feet for Heavy Fabrics

Having a powerful sewing machine for thick material is a great start, but it's only half the battle. Think of it this way: even the most powerful off-road truck won't get far in the mud with street tires. Your needles, thread, and presser feet are your machine's "tires"—without the right ones, that powerful motor just can't do its job properly.

Choosing the right needle is always the first, and arguably most important, step. A standard universal needle will almost certainly bend, break, or skip stitches when faced with something like denim or canvas. It just wasn't built for that kind of fight.

Needle and Thread Pairing Guide for Thick Materials

The needle’s only job is to punch a clean hole through the fabric, making way for the thread to follow and form a stitch. If the needle is too small or weak, you get skipped stitches, shredded thread, and broken needles. The thread, in turn, has to be strong enough to hold that seam together without snapping under pressure. It's a partnership, and both have to be right for the project.

To take the guesswork out of it, here’s a quick-reference guide for some of the most common heavy-duty fabrics you'll encounter.

| Material | Recommended Needle Type | Recommended Needle Size | Recommended Thread Weight |

|---|---|---|---|

| Denim | Denim (Jeans) | 90/14 to 110/18 | Heavy-Duty Polyester |

| Canvas | Universal or Denim | 100/16 to 110/18 | Upholstery or Bonded Nylon |

| Leather | Leather | 100/16 to 120/19 | Bonded Nylon or Polyester |

| Vinyl | Microtex or Leather | 90/14 to 110/18 | Heavy-Duty Polyester |

Getting these pairings right makes a world of difference. For example, if you're tackling that classic flat-felled seam on a pair of jeans, you'll want a size 100/16 Denim needle. It has a super sharp, reinforced point designed specifically to pierce that dense weave without tearing the fibers. Match it with a tough, heavy-duty polyester thread, and you'll get a seam just as durable as anything you'd find in a store.

This becomes even more critical for tricky materials. For instance, successfully working with leather fabrics is almost impossible without the correct needle and thread combo.

Your All-Terrain Tires: The Right Presser Feet

The presser foot is what keeps your fabric pinned down and feeding smoothly under the needle. Your standard, all-purpose foot is fine for everyday sewing, but thick, bulky, or sticky fabrics need something more specialized. These feet are your machine's all-terrain tires, giving you the grip and control you need to navigate tough spots.

Two of the most valuable feet you can own for heavy-duty sewing are the walking foot and the roller foot.

-

Walking Foot: Honestly, this is a must-have for anyone serious about sewing multiple layers. A walking foot has its own set of feed dogs on the top that work in sync with the feed dogs below. This creates a sort of conveyor belt action, pulling the top and bottom layers of fabric through at the exact same speed. It's the ultimate solution for preventing the layers from shifting and puckering, especially with things like canvas, upholstery, or quilts. To see just how it works, check out our complete guide on how to use a walking foot.

-

Roller Foot: This is your secret weapon for "sticky" materials like leather, vinyl, and PVC. Instead of a flat metal plate, this foot has little rollers that glide across the fabric's surface. This dramatically reduces friction, stopping the material from dragging or sticking to the foot, which is a common cause of uneven, messy stitches.

By simply adding the right needles, thread, and specialty feet to your toolkit, you're setting your machine up for success. You'll be amazed at how much easier it is to get strong, straight, and professional-looking stitches, every single time.

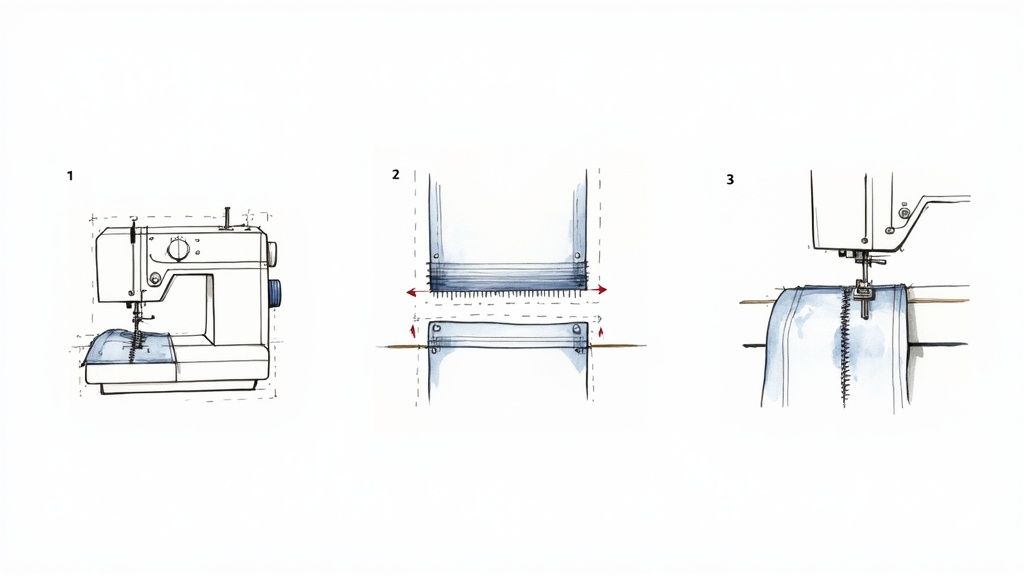

Your Step-by-Step Guide to Sewing Thick Materials

Okay, you've got the right machine and a few key accessories. Now for the fun part: putting it all to work. This is where a proper sewing machine for thick material really proves its worth. But here's a little secret—successfully stitching heavy fabrics isn't just about raw power. It's about knowing how to set up your machine and handle the unique quirks of each material.

Think of the next few steps as a hands-on workshop. We're going to give you the practical skills you need to tackle your next big project with total confidence. Every fabric has its own personality, and learning how to work with it is the difference between a homemade look and a professional finish. This is exactly the kind of know-how we love to build at bsewinn.com through our detailed training, empowering you to create whatever you can imagine.

Setting Up for Success

Before you even think about touching that foot pedal, a few simple adjustments will save you a world of frustration. Getting these settings right from the start helps you sidestep common headaches like skipped stitches, broken thread, or worse, damaged fabric.

-

Lengthen Your Stitch: Short stitches are the enemy of thick materials. They perforate the fabric, basically creating a "tear here" line that weakens your seam. Aim for a longer stitch length, somewhere in the 3.5mm to 5.0mm range. This is perfect for denim, canvas, and leather, giving you strength without sacrificing the material's integrity.

-

Tweak Your Tension: Heavy fabrics and thicker threads naturally create more resistance. You'll probably need to bump up your upper thread tension a notch or two. The goal is to get the "lock" (where the top and bobbin threads meet) to sit snugly right in the middle of your fabric layers. Always, always test on a scrap piece first!

-

Ease Up on the Presser Foot: If your machine has adjustable presser foot pressure, dial it back a little. This simple trick helps prevent the foot from leaving unsightly marks on materials like leather or vinyl. It also makes it much easier to glide over bulky seams without a fight.

Stitching Different Heavy Fabrics

With your machine dialed in, let's talk technique for a few common heavyweights. Each one requires a slightly different approach to get that durable, perfect-looking seam.

Sewing Denim and Canvas

Denim and canvas are tough customers. They're densely woven and demand a slow, steady hand. When you get to a thick spot, like a flat-felled seam where multiple layers overlap, resist the urge to power through it.

- Actionable Example: Let's say you're sewing the cuff on a denim jacket. Pop in a size 100/16 jeans needle and attach a walking foot. As you approach that bulky seam, use your machine's handwheel to manually walk the needle through the first few stitches. This gives you maximum control and prevents the needle from deflecting or snapping.

At B-Sew Inn, we're all about building real-world skills. Our online classes often feature tangible projects like making a sturdy canvas tote, where we guide you through every single step—from picking the right needle to finishing the seams for a result you'll be genuinely proud to replicate.

Sewing Leather and Vinyl

These materials play by different rules because every single needle hole is permanent. There's no ripping out a seam and starting over without leaving a trail of evidence. Precision is everything.

- Use Clips, Not Pins: Pins are a big no-no. They will leave permanent holes in your material. Instead, use binder clips or special sewing clips to hold your pieces together.

- Install a Roller or Teflon Foot: These feet are non-negotiable for "sticky" materials. They glide right over the surface instead of dragging or stretching the fabric, which is a common cause of wonky, uneven stitches.

- Test Tension Like You Mean It: For a vinyl upholstery project, getting the tension perfect is critical. Sew a test seam on a scrap piece. If you can see the top thread peeking through on the bottom, your top tension is too loose. If the bobbin thread is visible on top, it's too tight. Adjust it one number at a time until that stitch lock vanishes into the middle of the layers.

This kind of practical, project-based knowledge is essential, whether you're a home crafter or running a small business. In fact, the U.S. market for industrial sewing machines is growing steadily, largely thanks to the furniture and automotive industries that work with these exact materials. General-purpose industrial machines are particularly sought after for their versatility. You can learn more about the U.S. industrial sewing machine market on straitsresearch.com. Once you master these techniques, you'll be well on your way to creating beautiful, long-lasting items.

Troubleshooting Common Heavy-Duty Sewing Problems

Even with the perfect heavy-duty machine, you're going to run into challenges. That's just the nature of working with demanding, thick materials. Every now and then, your machine will let you know something's up. This isn't a sign of failure; it's just part of the process. Think of this as your go-to guide for figuring out what’s wrong and getting back to sewing with confidence.

When things go haywire, it’s easy to jump to conclusions and blame the motor or some mysterious internal part. But here's a little secret from years of experience: a surprising 90% of sewing machine issues trace back to one simple culprit—the needle. Before you start fiddling with tension dials or worrying about a trip to the repair shop, always check the needle first.

"Every frustrating sewing problem is solvable. By approaching it with a calm, step-by-step diagnostic, you not only fix the issue but also build a deeper understanding of your machine. This process turns challenges into learning opportunities."

This is exactly the philosophy we live by here at bsewinn.com. We believe that with the right guidance and support, you can overcome any creative hurdle. Our extensive online resources are designed to be that helpful voice over your shoulder, every step of the way.

Solving Skipped Stitches

Ugh, skipped stitches. They’re incredibly common when you’re wrestling with thick fabrics. This happens when the machine's hook misses the thread loop from the needle, failing to create a stitch. It’s your machine's way of politely saying, "Hey, something isn't quite right here!"

Try this simple diagnostic checklist:

- Check the Needle: Is it old? A needle gets dull after just 4-6 hours of sewing heavy stuff. Is it the right kind, like a Denim needle for denim? And is it inserted correctly, with the flat side facing the back? This is a huge one.

- Re-thread Everything: Don't just pull the thread through. Take both the top thread and bobbin out completely. With the presser foot up, re-thread the entire machine. This ensures the thread seats properly in the tension discs.

- Check Your Pairings: Are you using a thread that's too beefy for your needle's eye? The thread needs to glide through smoothly, not get squeezed.

Dealing with Constant Needle Breaks

A snapping needle is jarring, but it's almost always preventable. It happens when the needle gets pushed off course and smacks the metal throat plate instead of sailing cleanly through the hole.

Here’s what to investigate:

- Are You Forcing It? It's tempting to push or pull the fabric to "help" it along, but don't do it! Let the feed dogs do their job. Forcing the material is the #1 cause of a bent or broken needle.

- Is the Needle Right for the Job? Trying to punch through multiple layers of canvas with a little size 70/10 needle is asking for trouble. You need to match the needle to the material's thickness—grab a beefier 100/16 or 110/18 instead.

- Slow Down Over the Bumps: When you get to a super thick spot, like where the seams of jeans intersect, stop using the foot pedal. Use the handwheel to walk the needle stitch-by-stitch through the bulk. This gives you total control and prevents the needle from snapping under pressure.

Many of these issues are linked, but if you work through them one by one, you'll almost always find the culprit. For an even deeper dive, our comprehensive sewing machine troubleshooting guide can help you solve even the most stubborn problems.

Got Questions? We've Got Answers

Stepping into the world of heavy-duty sewing can feel a little daunting, especially when you're used to working with everyday fabrics. We hear a lot of the same questions from fellow makers, so we’ve put together some straightforward answers to help you sew with confidence.

Your Machine and Must-Have Tools

Choosing the right sewing machine for thick material is half the battle. Let's tackle some common questions about machine capabilities and the tools that make all the difference.

Can I really use my regular sewing machine for leather?

I wouldn't recommend it. While you might get away with a few stitches on a very thin piece of leather with a special needle, you're asking for trouble. A standard machine just doesn't have the motor strength to punch through consistently. You'll likely end up with skipped stitches, a pile of broken needles, or worse—a burnt-out motor. A heavy-duty or industrial machine is built for that kind of fight.

What exactly is a walking foot, and do I actually need one?

Think of a walking foot as a presser foot with its own little set of teeth on top. It works with your machine's feed dogs to grip and pull both the top and bottom layers of your fabric through at the same time. And yes, it's non-negotiable for thick stuff like canvas, multiple quilt layers, or upholstery fabric. Without it, your fabric layers will shift and pucker, leaving you with wavy, uneven seams. It's a total game-changer.

Needles, Thread, and Keeping Your Machine Happy

It's the little things that often have the biggest impact on your projects and how long your machine will last.

How often should I change my needle when I'm sewing denim?

Way more often than you think! A good rule of thumb is to pop in a fresh needle after every 4-6 hours of sewing on heavy denim. If you're starting a big new project, like a pair of jeans, just start with a new one. A dull needle is the #1 culprit for most stitching headaches when you're working with tough materials.

What kind of maintenance does a heavy-duty machine need?

Just like a car, your workhorse machine needs regular tune-ups to perform its best. You'll want to clear the lint out of the bobbin area after every project—that stuff builds up fast! Follow your manual for oiling instructions (some newer machines don't require it), and try to get it professionally serviced once a year. This keeps everything running smoothly, especially if you're putting in serious hours.

At B-Sew Inn, we know that getting the right machine is just the first step. That’s why we offer tons of resources, online classes, and training to support you on your creative journey, from day one to your most complex projects.

Ready to finally tackle those tough fabrics with a machine that won't back down? Check out the amazing selection of heavy-duty sewing machines we've personally curated at B-Sew Inn. It's time to find the power and precision your projects deserve.