Walking into a craft store and seeing a wall of thread can feel a little overwhelming, even for seasoned pros. Spools in every color of the rainbow, with different sheens, thicknesses, and mysterious labels... where do you even start? The truth is, choosing the right thread is just as important as picking your fabric. It's the literal glue holding your entire project together.

Your Guide to Choosing the Right Sewing Thread

Think of thread as the skeleton of your project. The right kind gives your seams strength and a beautiful, professional finish. The wrong one? It's a recipe for popped seams, frustrating puckers, and thread that snaps mid-stitch. I’ve been there, and it’s no fun.

But navigating the world of thread doesn’t have to be a headache. It really just boils down to a few key ideas that determine how a thread will behave in your machine and on your fabric. Once you get the hang of these, you'll be able to grab the perfect spool with confidence every time.

This guide is here to break it all down for you. We’ll look at the different materials and manufacturing tricks that give each thread its unique personality, so you can make the perfect match for any project you can dream up.

Key Concepts for Thread Selection

Before we get into the nitty-gritty of cotton versus polyester, let's cover the three fundamentals that apply to every single spool you'll ever buy:

- Fiber Type: This is what the thread is actually made of—things like cotton, polyester, or silk. The fiber is ground zero for the thread's strength, how much it stretches, and whether it can handle a hot iron.

- Thread Weight: Simply put, this is how thick or thin the thread is. It's the difference between a delicate, nearly invisible seam and a bold, decorative topstitch.

- Finishes and Ply: This is where the magic happens. Special coatings (like wax or mercerization) and the number of strands twisted together (the ply) can totally change a thread's durability, smoothness, and shine.

At B-Sew Inn, we're passionate about empowering crafters. Our custom sewing machine designs, comprehensive B-Sew Inn online classes, and extensive resources are all here to support you in creating beautiful, tangible projects you can be proud of, from start to finish.

With these basics under our belt, we’re ready to dive into the different kinds of thread you’ll find on the shelf. By the end, you'll be able to walk up to that wall of thread and know exactly what you’re looking for.

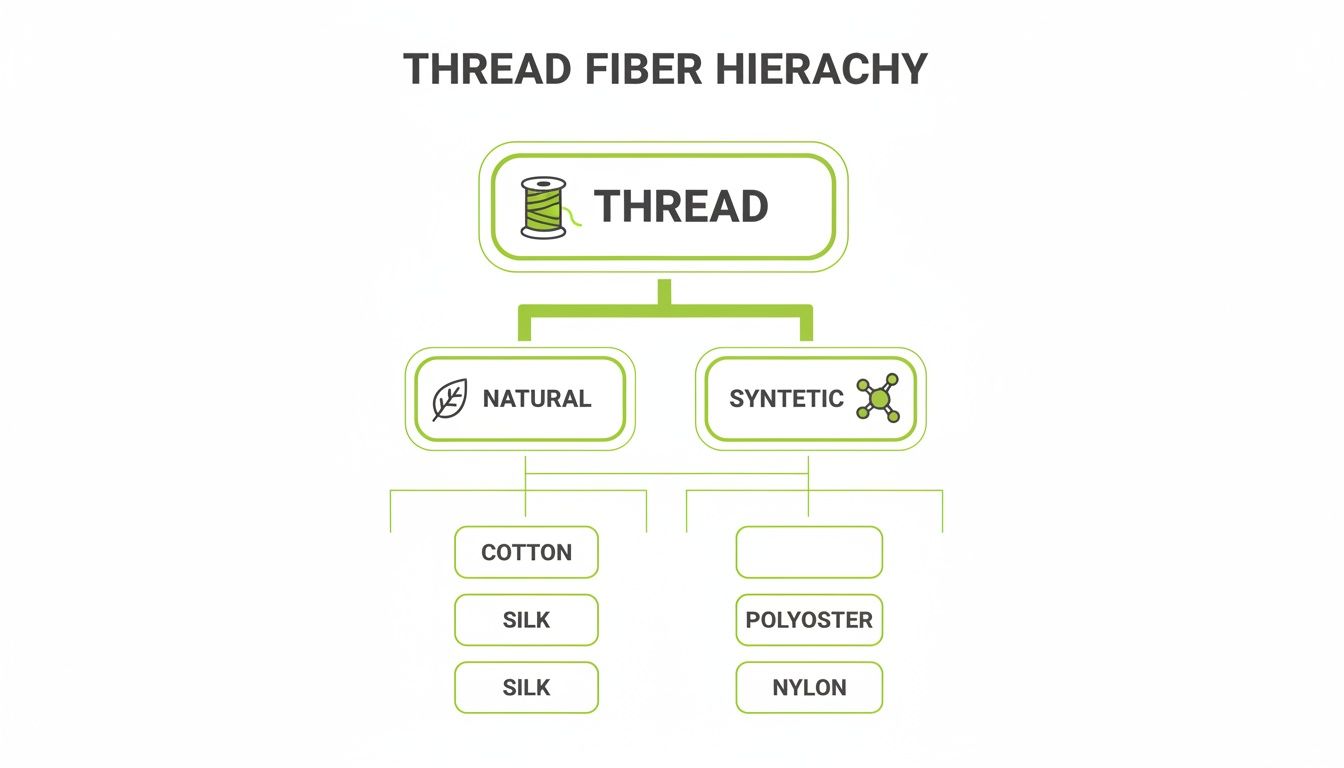

Decoding Thread Fibers: Natural vs. Synthetic

Every spool of thread has a story that starts with its fiber—the raw material that gives it strength, texture, and a specific job to do. Think of it like a chef picking the right oil for a dish; you wouldn't use heavy olive oil for a delicate pastry, right? The same goes for sewing. Choosing the right thread fiber is the first step toward seams that don't just hold, but look and feel incredible.

The two big families here are natural and synthetic, and they each have their own personality.

Natural fibers, like cotton and silk, come straight from nature—plants and animals. They're the classics, like a perfectly worn-in pair of jeans. People love them for their soft hand, ability to withstand a hot iron, and minimal stretch, which makes them a dream for projects needing stability.

Then you have the synthetics, like polyester and nylon, which are born in a lab. These are the high-performance fabrics of the thread world, engineered for brute strength, impressive stretch, and the kind of durability that scoffs at wear and tear. They’re also champs at resisting moisture and mildew, making them the go-to for everything from swimsuits to camping gear.

The Rise of Modern Fibers

It wasn't always this way. For centuries, the only options were natural fibers. They were beautiful, sure, but sometimes they just couldn't keep up with heavy use. When synthetic threads hit the scene, it was a total game-changer. Suddenly, we had threads with unbelievable strength and at a price point that was hard to beat.

Today’s thread aisle is a direct reflection of that shift. Synthetics are everywhere because they can handle the speed of industrial machines and the rigors of daily life way better than many of their natural cousins. You can get a great overview of the sewing thread market's history and growth on Global Growth Insights.

The choice isn't about which is "better," but which is right for what you're making. This is something we really drive home in our training—matching thread to fabric is the secret sauce for getting that professional finish every single time.

A Closer Look at Common Thread Types

Let's get to know the key players you'll find on the shelf. Each one brings something different to the table, and knowing which one to use is key to creating designs you can replicate.

- Cotton Thread: This is the quilter's soulmate. With almost no stretch, it creates beautifully flat, stable seams that are perfect for piecing together quilt blocks. Plus, it can take the heat from an iron like a champ, which is non-negotiable when you're pressing seams open.

- Polyester Thread: Meet the ultimate all-purpose workhorse. Its slight give makes it amazing for sewing clothes, especially with stretchy knit fabrics, because it moves with the fabric instead of popping a seam. It's also super strong and sheds very little lint.

- Nylon Thread: When you need serious muscle, you grab nylon. Known for its incredible strength and elasticity, this is the thread for heavy-duty jobs. Think upholstery, backpacks, and luggage—anything where a busted seam is simply not an option.

- Silk Thread: This is the luxury choice, and for good reason. Silk is unbelievably fine but surprisingly strong and flexible. It’s perfect for delicate fabrics like silk chiffon or lingerie, creating smooth seams that practically disappear into the fabric without adding any bulk.

Pro Tip: When in doubt, match your thread fiber to your fabric fiber. Sewing a 100% cotton quilt? Use cotton thread. Stitching a slinky polyester-blend dress? Polyester thread is your best bet. This ensures they'll behave the same way through washing, wearing, and ironing.

To help you see the differences at a glance, we've put together this quick comparison.

Natural vs. Synthetic Thread at a Glance

This table breaks down the core differences between the two main families of thread to help you make a quick decision for your next project.

| Feature | Natural Threads (e.g., Cotton, Silk) | Synthetic Threads (e.g., Polyester, Nylon) |

|---|---|---|

| Strength | Moderate to High | High to Very High |

| Stretch | Low to None | Low to High (Elasticity) |

| Heat Resistance | High (can be ironed at high temps) | Low to Moderate (can melt under a hot iron) |

| Common Uses | Quilting, heirloom sewing, embroidery | Garment construction, upholstery, activewear |

| Pros | Soft, absorbent, blends with natural fabrics | Durable, resists moisture/mildew, less lint |

| Cons | Can shrink, may produce more lint | Can be sensitive to heat, may not dye well |

Ultimately, having both natural and synthetic threads in your stash means you're prepared for whatever creative idea strikes next.

Understanding Thread Weight and Size

Okay, you've picked the right fiber for your project. That's a huge win! But the next piece of the puzzle is just as important: the thread's thickness, which we call thread weight or size.

Walking into the thread aisle can feel like trying to decipher a secret code. You'll see spools marked with things like 'Wt,' 'Tex,' and 'Denier.' It’s a bit confusing at first, but once you crack the code, you'll be able to grab the perfect thread for anything from the most delicate seams to bold, decorative topstitching.

Think of it like an artist choosing paintbrushes. You wouldn't paint a giant wall with a tiny detail brush, right? And you wouldn't try to paint fine lines with a massive roller. It’s the same with thread. A thick, beefy thread is designed to be seen and add strength, while a fine, whisper-thin thread is meant to blend in and practically disappear.

Getting this match right is a cornerstone of creating work that looks polished and professional. Here at https://www.bsewinn.com, we're all about empowering crafters with this knowledge through our guides and tutorials, ensuring you feel confident replicating any design on your machine.

The Weight (Wt) System Explained

For most of us sewing at home, the system you'll see 90% of the time is the Weight (Wt) system. The main rule is simple, even if it feels a little backward at first: the lower the number, the thicker the thread.

So, if you pick up a spool labeled 30 Wt, you’re holding a pretty hefty thread. This is what you want when you need your stitches to make a statement. It's perfect for tangible examples like:

- Topstitching on a pair of jeans or a sturdy tote bag.

- Decorative quilting where you want that beautiful stitch pattern to pop.

- Buttonholes on heavy coats or jackets that need to be extra tough.

On the flip side, a spool of 50 Wt is your everyday, all-purpose workhorse. This is my go-to for piecing quilt blocks and sewing garment seams. If you see 60 Wt or 80 Wt, you're getting into much finer territory—ideal for delicate appliqué or heirloom sewing where the goal is for the stitches to be nearly invisible.

This diagram gives you a great visual of how threads are categorized right from the start. Whether a thread begins as a natural or synthetic fiber determines its core properties, like how much it stretches and where it will perform best.

A Quick Look at Tex and Denier

While you'll mostly be dealing with the 'Wt' system, you might bump into other sizing methods, especially if you buy industrial or specialty threads. For Tex and Denier, just flip the rule you just learned: the higher the number, the thicker the thread.

- Tex: This system is based on how many grams 1,000 meters of the thread weighs. So, a T-70 thread is way heavier than a T-24.

- Denier: Very similar to Tex, but this one measures the weight in grams of 9,000 meters of thread. You’ll often see this used for silky, fine threads for embroidery.

Don't get bogged down trying to memorize conversion charts. Just know which system you're looking at. If you really want to get into the weeds, you can explore our complete sewing thread size guide and become a true thread expert.

The one thing to drill into your brain for home sewing is this: In the Weight (Wt) system, low number = thick thread, high number = thin thread. Honestly, that one rule will get you through almost every project you tackle.

Figuring out thread weight gives you a whole new level of creative control. It’s the difference between seams that are just strong and seams that are both strong and perfectly suited to the look and feel of your project.

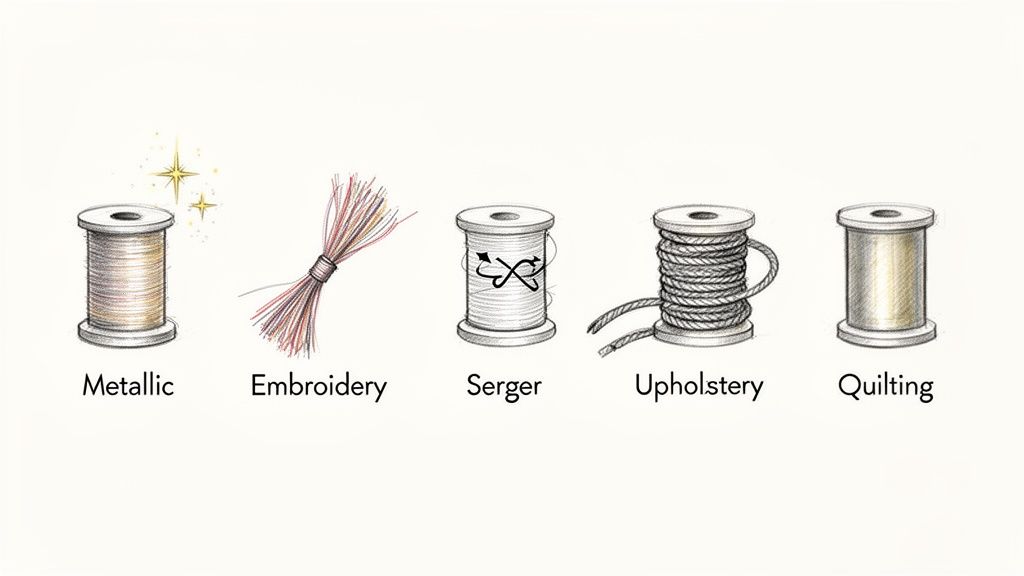

Once you’ve got a handle on the basic fibers and weights, the real fun begins. Welcome to the world of specialty threads—the secret sauce for taking your projects from "homemade" to "handmade professional."

Think of these threads as the difference between a pencil sketch and a full-color painting. They’re engineered to do one job incredibly well, whether that’s adding dazzling decoration or providing brute strength. Using the right one is how you get those crisp, store-bought details that make people ask, "You made that?!"

Embroidery Thread for Dazzling Designs

Embroidery thread is all about the bling. It’s designed to sit proudly on top of the fabric and catch the eye, creating everything from delicate monograms to big, bold designs. The two workhorses you'll run into most are Rayon and Polyester.

- Rayon Embroidery Thread: This is your go-to for a brilliant, silky sheen. Rayon has a gorgeous luster that makes colors pop, and it’s soft and flexible, so it drapes beautifully on clothing.

- Polyester Embroidery Thread: When you need your design to last forever, grab polyester. It's tough as nails, won't fade or bleed in the wash, and can even stand up to bleach. This makes it a no-brainer for kids' clothes, towels, or any item that's going to see a lot of wear and tear.

Quilting and Serger Threads for Strength and Flexibility

These two might seem similar, but they're designed for opposite jobs. One needs to be rock-solid, while the other needs to move and groove.

Quilting thread is built for endurance. Usually made from 100% mercerized cotton, it’s strong, smooth, and has very little lint, which is essential for keeping your machine happy during long quilting sessions. Its whole purpose is to lock the quilt top, batting, and backing together for decades to come.

On the flip side, serger thread (or overlocking thread) is all about stretch. It’s typically a fine polyester or nylon that comes on massive cones—because your serger will devour it at an incredible rate! It creates flexible seams that can stretch with knit fabrics, preventing those dreaded popped stitches when you pull on a t-shirt or leggings.

Choosing the right thread is not just a technical step; it’s a creative decision. With support from B-Sew Inn's custom designs and training, the thread you select can add subtle strength or become the star of the show, allowing you to replicate any design with confidence.

Heavy-Duty and Decorative Threads

Now we're getting into the real problem-solvers and showstoppers of the thread world. These are the threads you pull out for the toughest jobs or when you want to add a little extra magic.

Upholstery Thread: Need a seam that absolutely, positively cannot fail? This is what you reach for. Made from bonded nylon or heavy-duty polyester, this thick, rugged thread is made for high-stress projects like outdoor cushions, leather bags, or reupholstering your favorite armchair. To learn more about what makes a thread truly tough, check out our guide on finding the strongest sewing thread for your projects.

Metallic Thread: Time to add some sparkle! Metallic thread is basically a synthetic core wrapped in shiny foil, perfect for holiday projects, formal wear, or just adding a touch of glamour. It can be a little fussy, though. Pro tip: use a special metallic needle and slow your machine speed way down to keep it from shredding. A little patience is all it takes for a stunning, glittery finish.

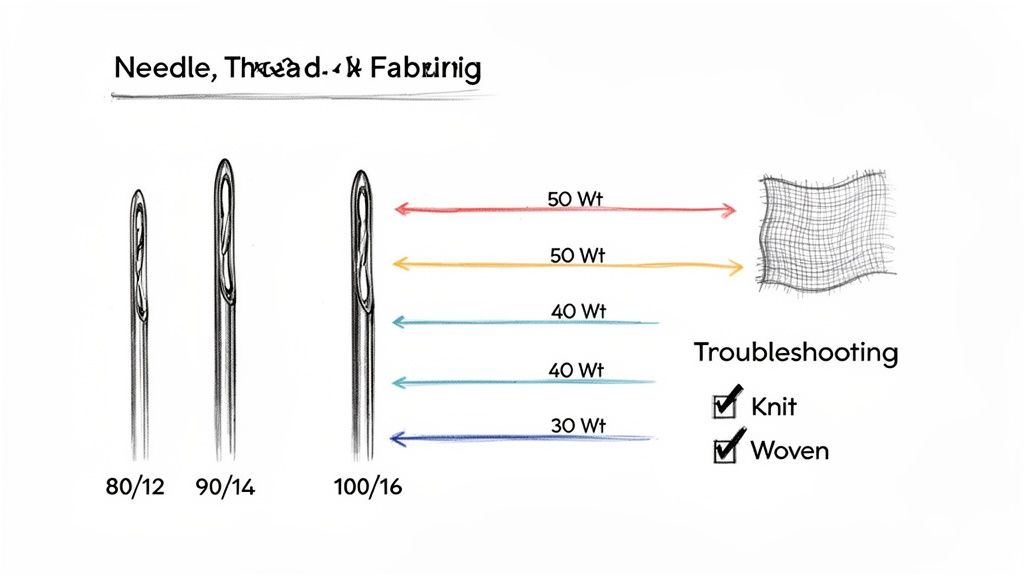

How to Match Thread to Needles and Fabric

Every perfect stitch is the result of a little team effort happening right at your machine. It’s a delicate dance between your thread, needle, and fabric. When you get this combination right, you get beautiful, strong seams. When it's wrong... well, that's when you get frustrating skipped stitches, shredded thread, and puckered fabric.

Think of your sewing needle as a tunnel builder. It’s job is to create the perfect path for the thread to follow.

If that tunnel (the hole in the fabric and the needle's eye) is too small, the thread gets scraped, frayed, and eventually snaps. But if the tunnel is way too big, the stitch can't form correctly, leaving you with wobbly, unstable seams. This is why getting the relationship between thread weight and needle size is so critical.

Here at B-Sew Inn, we're all about empowering sewers with this kind of foundational knowledge. It’s the secret sauce behind every successful project, and it's why our custom sewing machine designs and online training focus on mastering these details from the get-go.

The Golden Rule of Needle and Thread Pairing

The core principle is actually pretty simple: thicker threads need larger needles. A bigger needle has a larger eye, which lets that hefty thread glide through without a fight. It also punches a slightly larger hole in the fabric, clearing a smooth path for the thread to settle into the seam perfectly.

On the flip side, using a fine thread with a giant needle is a recipe for disaster. The thread will just flop around in the oversized hole, leading to loose, weak stitches.

Let's look at this in practice:

- For heavy 30 or 40 Wt thread (think topstitching on a denim jacket or decorative quilting on a throw pillow), you'll want to grab a larger needle, like a 90/14 or 100/16.

- For your standard, everyday 50 Wt all-purpose thread, a mid-range 80/12 needle is almost always the perfect match.

- Working with delicate 60 or 80 Wt thread for fine appliqué or heirloom sewing? You'll need a smaller 70/10 or 75/11 needle.

Fun fact: A correctly sized needle eye reduces friction on the thread by over 50%. This dramatically cuts down the chances of shredding and breaking. Just checking this one thing is one of the most effective troubleshooting steps you can take!

Matching Thread Fiber to Fabric Type

It's not just about thickness, though. The type of fiber your thread is made from should play nicely with your fabric. The idea is to use a thread that will act like the fabric it’s holding together, ensuring your project wears, washes, and ages as one cohesive piece.

A great rule of thumb is to match thread fiber to fabric fiber.

- Sewing stretchy knits? Polyester thread is your best friend. It has just enough give to stretch with the fabric, which is the key to preventing popped seams when the garment moves.

- Piecing a 100% cotton quilt? It makes sense to use a cotton thread. It will wear at the same rate as the fabric and can handle the high heat from your iron during pressing without any issues.

- Stitching a delicate silk blouse? A fine silk thread will practically disappear into the fabric, creating an invisible, professional finish without adding any bulk.

A Quick Reference for Success

Getting this combination right is a game-changer for flawless sewing. By mastering this, you'll be able to replicate complex sewing machine designs with professional results.

For a quick cheat sheet, here’s a handy table to help you make the right choice every time.

Thread Weight to Needle Size Quick Reference Chart

This chart is your go-to for quickly matching common thread weights (Wt) to the right universal sewing machine needle size. Keep it bookmarked!

| Thread Weight (Wt) | Common Use | Recommended Needle Size (Universal) |

|---|---|---|

| 30 Wt | Topstitching, Decorative Quilting | 100/16 or 110/18 |

| 40 Wt | Machine Quilting, Buttonholes | 90/14 |

| 50 Wt | General Piecing, Garment Seams | 80/12 |

| 60 Wt | Fine Piecing, Appliqué | 75/11 |

| 80 Wt | Heirloom Sewing, Bobbin Thread | 60/8 or 70/10 |

By taking a moment to follow these guidelines, you're setting your machine—and your project—up for success. You’ll be creating strong, beautiful stitches that will stand the test of time.

Tips for Storing and Troubleshooting Your Thread

Once you’ve found the perfect thread for your project, the next step is taking care of it and knowing what to do when things go sideways at your machine. A little bit of know-how can save you a world of frustration.

Think of your thread collection like a pantry full of spices. If you leave your paprika out in the sun, it loses its color and punch. Thread is the same way—expose it to the elements, and it’ll get brittle and weak over time. Good storage isn't just about being neat; it's about making sure every spool is ready to perform when you need it.

These are the kind of real-world tips we love sharing at B-Sew Inn. We’re dedicated to supporting you long after you buy something from us, with online classes and resources to help you create flawlessly from start to finish.

Best Practices for Thread Storage

Sunlight, dust, and humidity are the three biggest enemies of your thread. UV rays fade beautiful colors and weaken the fibers, and dust is a sneaky culprit that can get pulled right into your machine’s tension discs and cause all kinds of trouble.

Luckily, good storage is simple. You don't need a fancy, expensive setup. The main goal is just to keep your thread clean, dry, and out of direct sunlight.

- Go for Clear Containers: See-through plastic boxes with lids are perfect. They keep the dust out and let you see your entire color palette in a single glance.

- Try a Thread Rack: Wall-mounted racks are great for organization, but just be sure to hang them away from any sunny windows.

- Avoid Extreme Temps: Don't stash your thread in a sweltering attic. A stable, room-temperature spot is ideal for preserving its strength.

Keeping thread in top condition is one of the easiest ways to ensure consistent stitch quality and avoid frustrating breaks. A little bit of care really does go a long way.

Troubleshooting Common Thread Problems

Even with the best thread and a top-of-the-line machine, things can still go wrong. When your machine starts acting up, don't panic! Most issues are surprisingly easy to fix with a few quick checks.

Thread breaking or shredding is probably the most common headache for sewers. Before you blame the thread, run through this simple checklist:

- Check Your Needle: Seriously, when was the last time you changed it? A dull, bent, or wrong-sized needle is the #1 cause of shredded thread. Pop a new one in!

- Rethread Everything: It sounds too simple, but it often works. Take both the top thread and bobbin out and rethread your machine from scratch. Make sure the presser foot is up when you thread the top.

- Tweak Your Tension: If you’re seeing loops or your fabric is puckering, your tension is likely the culprit. Grab a scrap of fabric and test your stitches, adjusting the top tension dial in small turns until it looks right.

This hands-on, problem-solving approach is a huge part of the support we offer at B-Sew Inn. We want to empower you to really understand your machine and materials, turning those frustrating moments into learning opportunities. It’s a passion shared by creators worldwide—you can learn more about the sewing thread market's expansion on grandviewresearch.com.

Got Questions? We've Got Answers

Even after you've learned the ropes, a few questions always seem to come up. Here are some quick answers to the things we get asked most often.

Can I Really Use All-Purpose Polyester Thread for Everything?

I get this question all the time, and while all-purpose poly is a fantastic workhorse, it’s not always the perfect choice. Think of it this way: if you're making a beautiful 100% cotton quilt, you’ll want to use cotton thread. Why? Because the cotton thread will wear, shrink, and age right along with your fabric, keeping everything looking harmonious for years.

On the flip side, if you're working with delicate silk or fine lingerie, a silk thread is going to give you that gorgeous, invisible finish that just melts into the fabric. Using the right specialty types of sewing thread is what elevates your work from just "done" to truly professional.

How Do I Know if My Thread Is Too Old?

We've all inherited a beautiful wooden box of old thread spools. But before you use them, you need to check if they're still up to the job. Old thread gets brittle and weak, and it’ll just snap over and over again while you're trying to sew. It's incredibly frustrating!

Here’s a quick test: pull off about a 12-inch piece and give it a sharp tug. If it snaps with barely any effort, it's past its prime. Good thread should put up a little fight. To keep your new thread from meeting the same fate, store it away from direct sunlight and dust.

Choosing the right thread isn’t just about making a seam; it’s about investing in the life and beauty of whatever you create. Taking that extra minute to match your thread to your project ensures your hard work will be loved and last for years.

What’s the Big Deal with Quilting Thread?

Quilting thread is a whole different beast from your standard all-purpose thread, and for good reason. It’s specially engineered to be much stronger and to produce way less lint. That's a huge plus when you're stitching through multiple layers.

Most quilting thread is made from mercerized cotton, which gives it a beautiful, smooth sheen that helps it glide through the quilt sandwich. This extra strength is absolutely essential to handle the high speeds of machine quilting and to make sure your quilt holds up beautifully, wash after wash.

Here at B-Sew Inn, we're all about empowering your creativity with the best tools and knowledge out there. Our custom sewing machine designs, extensive resources, and expert training are all designed to help you bring any project to life. Stop by https://www.bsewinn.com to see what's new.