When your project absolutely has to hold together, grabbing the strongest sewing thread you can find is a must. For the really tough stuff—like leatherwork, outdoor gear, and upholstery—the pros turn to bonded nylon and bonded polyester. These threads are the champions of the sewing world, offering incredible strength and resistance to wear and tear that your standard threads just can't match.

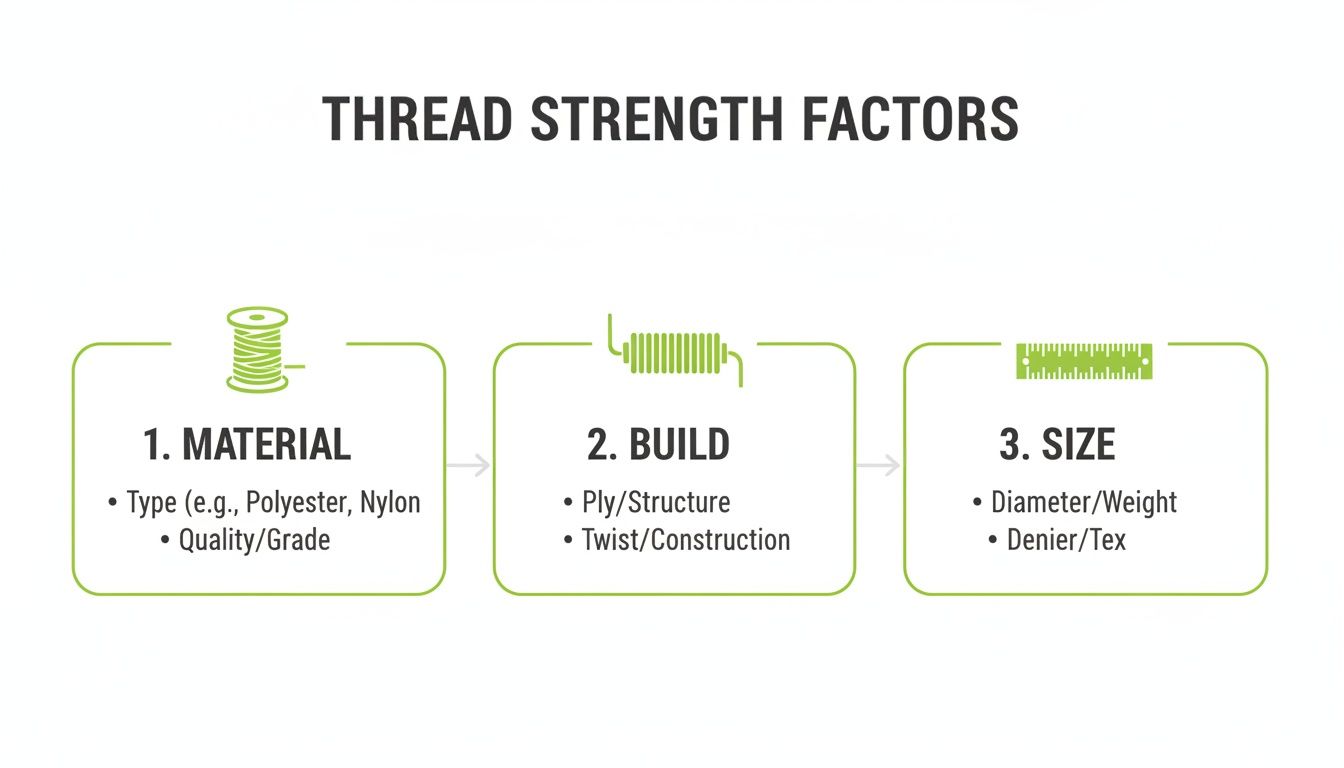

What Actually Makes Sewing Thread Strong?

Picking the strongest thread isn't as simple as grabbing the thickest spool on the rack. Real strength is a mix of smart material science, clever construction, and knowing how to read a few key numbers on the label. Nailing these basics is the first step to creating seams that are truly built to last.

Picture a single, delicate wisp of cotton. By itself, it’s incredibly fragile. But when you twist thousands of those fibers into a tight rope, they become immensely strong. Sewing thread works on the very same principle, but its ultimate power comes down to three specific factors.

Material: The Foundation of Strength

Everything starts with the raw material. While natural fibers like cotton are lovely and soft for quilting, they don't stand a chance against synthetics when you need sheer brute force. This is where engineered materials like nylon and polyester really shine.

Synthetic threads are the heavyweights in the industry, hands down. Polyester and nylon, in particular, are prized for their exceptional tensile strength (how much you can pull on them before they snap), resistance to abrasion, and overall durability. It's no surprise that the synthetic segment dominates the global sewing thread market, which was valued at a whopping USD 3.79 billion. Synthetics are the go-to because they deliver unbeatable performance for industrial and high-stress jobs.

Thread Construction: How Fibers Become a Force

Just as important as what a thread is made of is how it's put together. The way individual fibers are assembled determines how well the thread will resist fraying, friction, and snapping under the stress of sewing.

- Ply and Twist: Most threads are actually made of multiple strands (called "plies") twisted together. A tighter twist results in a smoother, stronger thread that's far less likely to shred or unravel as it zips through your machine and fabric.

- Bonding: This is a game-changer. The process involves coating the thread with a special resin that essentially glues all the fibers together. A bonded thread behaves like a single, solid cord, making it incredibly tough against abrasion. It's the perfect choice for sewing through unforgiving materials like leather or thick layers of canvas.

- Core Spun: This is a clever hybrid construction. It starts with a super-strong continuous filament core (usually polyester) and wraps it with a staple fiber like cotton. This gives you the best of both worlds: the easy sewability and classic look of cotton with the rock-solid strength of a polyester core.

Size and Weight: Decoding the Numbers

Finally, a thread's thickness is a straightforward clue to its strength. The technical terms are weight (wt), denier, or Tex. Simply put, thicker threads have more fibers packed into them, making them inherently stronger and better suited for heavy-duty work.

A common mistake is thinking all "heavy-duty" threads are created equal. The reality is, understanding the specific Tex or denier number gives you a much more precise measure of strength, letting you match your thread to your project with confidence.

Learning to read these numbers is a skill worth having. A 40wt thread is thicker and stronger than a 60wt thread. In the Tex system, a higher number (like Tex 70) means a much stronger thread than a lower one (like Tex 27). For a deeper dive, our complete sewing thread size guide breaks it all down.

Let's quickly recap what really makes a thread tough.

Key Factors That Determine Thread Strength

This table gives a quick summary of the primary characteristics that define a sewing thread's durability and strength.

| Strength Factor | What It Means for Your Project | Why It Matters for Durability |

|---|---|---|

| Material | Synthetics like nylon and polyester are best for high-stress seams. | They resist snapping, abrasion, UV rays, and moisture far better than natural fibers. |

| Construction | Bonded and core-spun threads prevent fraying and handle friction better. | A solid construction ensures the thread doesn’t weaken as it’s sewn or during use. |

| Size/Weight | Thicker threads (e.g., lower weight number, higher Tex number) offer more raw strength. | More fibers mean more breaking strength, crucial for holding heavy materials together. |

Once you understand these three pillars—material, construction, and size—you can look at any spool and have a really good idea of what it’s capable of. This knowledge takes the guesswork out of choosing a thread, empowering you to pick the right one every time and ensure your creations are as durable as they are beautiful.

Comparing the Top High-Strength Threads

Alright, now that we've pulled back the curtain on what gives a thread its muscle, let's meet the heavyweights of the sewing world. Choosing the right thread is a lot like picking the right tool for a job. You wouldn't use a tiny screwdriver on a massive bolt, right? The same logic applies here.

The thread that's perfect for a tough leather satchel might completely fall apart on a boat cover that lives in the sun all year. We're going to walk through the big players—bonded nylon, bonded polyester, and a few other tough customers—so you can pick a winner every time.

Think of a thread's strength as a combination of three key ingredients: its material, its construction, and its size. Get these three right, and you've got a thread that can handle just about anything you throw at it.

Bonded Nylon: The Abrasion-Resistant Powerhouse

When your project is going to see a lot of wear, tear, and friction, bonded nylon is your go-to. This stuff is an absolute workhorse. It's the standard for things like leatherworking, automotive upholstery, and tactical gear for a reason—it just doesn't quit.

What makes it so tough? The "bonded" part is the secret sauce. A special resin coating essentially glues all the tiny filaments together into one smooth, solid cord. This stops it from fraying and shredding as it punches through dense materials like thick leather or multiple layers of canvas.

- Key Strengths: Insane tensile strength, top-notch abrasion resistance, and just enough stretch to give seams some flexibility under pressure.

- Best Uses: Leather goods (think wallets, belts, and bags), heavy-duty canvas projects, luggage, and sports equipment.

- A Word of Caution: Nylon’s one kryptonite is UV light. If left in the sun for too long, it can get brittle over time, so it's not the best choice for permanent outdoor gear.

Bonded Polyester: The Outdoor Champion

If your project is going to live outside, bonded polyester is the undisputed king. It might have a little less raw strength and friction resistance than nylon, but its superpower is fending off the elements. It laughs at UV rays, moisture, and mildew.

This makes it the industry standard for pretty much anything that gets exposed to sun and rain. From marine upholstery baking on a boat deck to patio cushions caught in a downpour, bonded polyester holds its ground without fading or breaking down. Plus, it has very little stretch, so your seams won't sag over time.

- Key Strengths: Amazing UV resistance, totally unfazed by mildew and moisture, holds its color beautifully, and creates incredibly stable seams.

- Best Uses: Boat covers, awnings, sails, outdoor furniture cushions, tents, and tarps.

- Good to Know: While it's incredibly durable, it's a bit less forgiving with friction than nylon. Just make sure your machine is dialed in correctly to avoid any snags.

Other Heavy-Duty Contenders

Beyond the two main players, a few other specialty threads have carved out their own niches. These are fantastic options when a project has a very specific need.

Heavy-Duty Polyester (Upholstery Thread)

This is the tough, non-bonded thread you’ll often find at your local fabric store. It’s a wonderful, easy-to-find choice for indoor upholstery projects, mending denim, or any time you just need something stronger than your average all-purpose thread. It might not be as beastly as its bonded cousins, but most home sewing machines can handle it without a fuss.

Topstitching Thread

Designed to be seen, this thicker thread adds both strength and a sharp, decorative finish. You'll see it on jeans, bags, and jackets where the seam is part of the style. It's usually a polyester or a poly-cotton blend that really makes your stitches pop.

Speaking of projects where looks and strength both matter, quilting is a perfect example. The thread has to be strong enough to hold everything together for years but also complement the design. To dive deeper, check out our guide on the best thread for machine quilting.

To make things even clearer, let's put these threads head-to-head.

High-Strength Thread Comparison Guide

Here's a quick side-by-side look at the heavy hitters. Think of this as your cheat sheet for choosing the right thread for your next tough project.

| Thread Type | Key Strengths | Best For Projects Like... | Things to Consider |

|---|---|---|---|

| Bonded Nylon | Superior abrasion resistance, high tensile strength, slight stretch for resilience. | Leatherwork, upholstery, footwear, luggage, tactical gear, heavy canvas. | Can degrade with prolonged UV exposure, not ideal for permanent outdoor use. |

| Bonded Polyester | Excellent UV and mildew resistance, low stretch, holds color well. | Marine applications (boat covers, sails), awnings, outdoor furniture, tents. | Slightly lower abrasion resistance than nylon. |

| Heavy-Duty Polyester | Good strength, widely available, easy for home machines to handle. | Indoor upholstery, denim, bags, general repairs requiring more than all-purpose thread. | Not as strong or abrasion-resistant as bonded versions. |

| Topstitching Thread | Thick and decorative, adds visible strength to seams. | Visible seams on jeans, jackets, bags, and decorative finishes. | Primarily for aesthetics; not typically used for construction seams. |

At the end of the day, the "strongest" thread is the one that’s perfectly suited for the job at hand. By understanding what each of these threads brings to the table, you're ready to tackle any heavy-duty project with confidence.

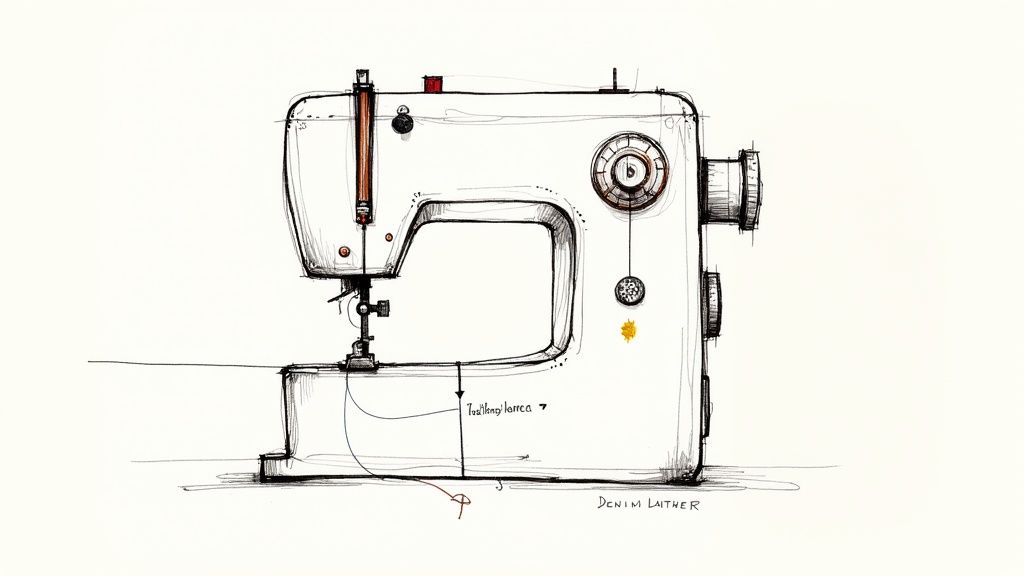

Matching Strong Thread with the Right Machine Setup

Here’s the thing: even the strongest thread in the world is useless if your machine isn’t set up to handle it. Trying to force a thick, heavy-duty thread through a machine that’s not ready for it is a recipe for pure frustration. We’re talking skipped stitches, shredded thread, and tangled messes that make you want to quit.

But don’t worry, a few key adjustments can get your machine humming along, giving you that smooth, professional finish you're after.

Think of it this way: your needle, thread, and machine are a team. For that team to win, every player has to be in the right position. Using a thick thread with a tiny needle is like asking a linebacker to run a marathon in ballet slippers—it’s just not going to work.

Your Needle is the Most Important Teammate

The single most critical adjustment is picking the right needle. Simple as that. The eye of a standard needle is way too small for heavy-duty thread. As the thread zips through, the friction shreds and snaps the fibers before they even have a chance to form a stitch.

You absolutely have to match your needle size to your thread weight. For beefier threads like bonded nylon or upholstery-weight polyester, you need a needle with a bigger eye and a much stronger shaft.

These are my go-to options for any heavy-duty project:

- Denim/Jeans Needles: These guys have a super sharp, reinforced point that punches through dense fabrics without bending. Look for larger sizes like 16/100 and 18/110—they’re perfect for heavy threads.

- Leather Needles: With a unique wedge-shaped point, these needles slice a clean hole through leather and vinyl instead of just pushing through. This cuts down on resistance and stops skipped stitches in their tracks.

- Topstitching Needles: These are designed specifically for thick, decorative threads. They have an extra-large eye and a deeper groove to protect the thread from friction.

And a pro tip: always, always install a fresh needle before starting a heavy-duty project. A dull or bent needle is a primary cause of thread breakage, no matter what size it is.

Making Critical Machine Adjustments

Once you’ve got the right needle in, a couple of quick tweaks to your machine's settings will get that thread flowing smoothly. Heavy-duty thread just behaves differently, so you need to give it a little more room to move.

The goal is to reduce friction and stress on the thread at every single point of its journey. By loosening the tension and slowing your speed, you let the machine form strong, even stitches without fighting against the thread.

First, loosen your upper tension. Thicker thread takes up more space in the tension discs. A setting that’s perfect for a 50wt thread will basically strangle a Tex 70 thread, causing it to shred. As a starting point, turn the tension dial down by one or two full numbers. If you want a deep dive on this, check out our guide on perfecting your tension adjustment on a sewing machine.

Next, slow down your sewing speed. Flying at top speed generates a surprising amount of friction and heat, which can weaken or even melt synthetic threads. A steady, controlled pace gives the machine time to form each stitch perfectly and keeps your needle from getting too hot.

The bsewinn.com Advantage for Tough Projects

While most home sewing machines can handle some heavy-duty work with these adjustments, they’ll start to struggle with the really tough materials and the strongest threads. That’s where specialized equipment really makes a difference.

At bsewinn.com, we design custom sewing machines specifically engineered for these kinds of ambitious projects. Our machines have powerful motors and robust, all-metal frames that won’t strain when you're sewing thick canvas or leather. They give you the reliability and support you need to bring your creative visions to life. With our online classes and extensive resources, we’re committed to empowering crafters like you to stop fighting your materials and start focusing on your craft.

How to Sew Durable Seams That Never Fail

Picking out a heavy-duty thread is a great start, but it's only one piece of the puzzle. The real secret to seams that just won't quit? It all comes down to your technique—how you actually put that thread to work. You can have the best thread in the world, but if you sew it with a weak, sloppy stitch, you'll get a weak, sloppy seam every time.

Think of it like making a strong chain. The thread is one link, but the stitches are the other links. If your stitches are weak, the whole chain will break under pressure. With a few simple adjustments to your technique, you can make sure every seam you sew is as tough as the thread holding it together.

Optimizing Your Stitches for Maximum Strength

The kind of stitch you choose and how long you make it can completely change the game, especially when you’re wrestling with thick fabrics and strong thread. Not all stitches are created equal, and knowing which one to use is the first step toward building a seam that lasts a lifetime.

When you're working with beefy materials like canvas, leather, or a few layers of denim, a longer stitch length is your best friend. I usually aim for something between 3.0mm and 4.0mm. If your stitches are too short, you’re basically punching too many tiny holes close together. This creates a "perforated line"—like on a tear-off coupon—that can actually make the fabric weaker and more likely to rip. Longer stitches spread that stress out, giving you a much stronger hold.

And for those high-stress areas that take a constant beating—think bag straps, cushion corners, or the crotch seam on a pair of work pants—a little reinforcement is absolutely non-negotiable. Here are my go-to techniques for locking down those critical spots:

- Backstitching: This one is a must. Always start and end your seams with a few backstitches. It locks the thread in place and is the simplest way to stop your hard work from unraveling.

- Triple Stitch (or Stretch Stitch): A lot of modern machines have this setting. It sews two stitches forward and one back, over and over again. The result is a thick, incredibly strong seam with a little bit of give. It’s almost impossible to break.

- Bar Tacks: Look at the corners of your jeans' pockets. See those dense, zigzag stitches? Those are bar tacks. They’re perfect for spots like belt loops or pocket corners because they distribute all that pulling force over a wider area.

Finishing Seams to Prevent Fraying

Here's something a lot of people overlook: fraying. When the raw edges of your fabric start to unravel, those loose threads can wiggle their way right out of the seam. Before you know it, the seam weakens from the inside out and falls apart. Properly finishing your seams encases those raw edges, protecting them for the life of your project.

Seam finishing is the unsung hero of durable sewing. It’s the internal scaffolding that keeps your project structurally sound, ensuring that friction and washing don't compromise the integrity of your hard work.

At bsewinn.com, we’re all about teaching techniques that lead to professional, long-lasting results. Our online classes and resources are designed to help crafters move beyond the basics and create things that are truly built to last. Finishing your seams is a core principle we teach because it makes your work look better and live longer.

Best Practices for Lasting Durability

Beyond your machine settings, a few good habits can make a world of difference for your seams and your thread.

The sewing thread market is projected to grow from USD 3.66 billion to USD 4.91 billion by 2035, and that boom is largely thanks to the industrial demand for high-strength synthetics like polyester and nylon. There's a good reason for it—industry data shows polyester’s chemical resistance can cut down on degradation by up to 50% compared to cotton, making it a no-brainer for anything that might get wet.

To get that same industrial-strength performance in your own projects, try these tips:

- Store Thread Properly: Keep your spools out of direct sunlight and away from dust. UV rays can weaken even the toughest synthetic fibers over time, and dust can sneak into your machine’s tension discs and cause all sorts of headaches.

- Use Quality Notions: Don't pair a fantastic thread with a cheap needle. A poorly made needle can have tiny burrs on it that will shred your thread as you sew, completely defeating the purpose of choosing a strong one in the first place.

- Test on Scrap Fabric: I can't stress this enough. Before you touch your actual project, always run a test on a scrap of the exact same fabric. This five-minute check lets you dial in your stitch length, tension, and needle choice, and it can save you hours of seam-ripping later.

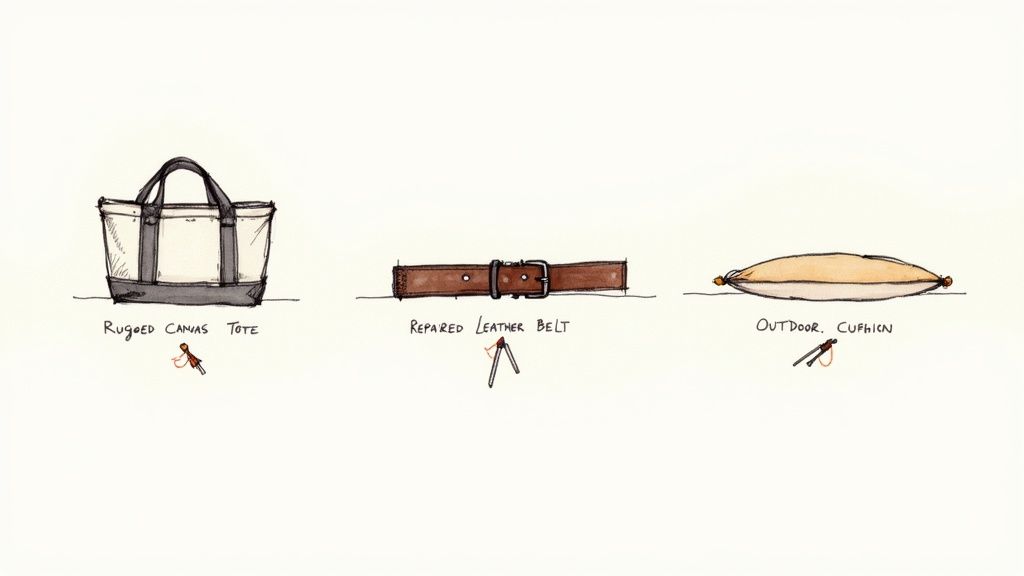

Time to Sew: Heavy-Duty Project Ideas

Alright, you've got the theory down and know the technical ins and outs. Now for the really fun part—getting your hands dirty and putting that knowledge to the test. Seeing how the strongest sewing thread holds up in a real-world project is the absolute best way to build your confidence and truly get a feel for what it can do.

This section serves as a comprehensive "how-to" guide, showcasing tangible examples that crafters can replicate. We’ll cover the exact combo of thread, needle, and machine settings you need to create pieces that are built to last. It’s this hands-on, practical approach that we're all about at bsewinn.com, giving you the tools and know-how to nail any project you dream up through our custom sewing machine designs and supportive online classes.

Project 1: A Seriously Rugged Canvas Tote Bag

A sturdy canvas tote is a classic for a reason. It's the perfect first project to test your new heavy-duty skills because it needs to take a beating—from heavy loads to constant rubbing and friction. The right thread choice here is everything.

We’re not just making a bag; we’re making one where the straps won’t give out and the seams won’t pop. You'll need a bonded thread to stand up to the abrasive canvas, which can chew up weaker threads as you sew.

Your Setup Guide:

- Fabric: Grab some 18 oz waxed canvas or heavy cotton duck. This stuff is tough, water-resistant, and practically begs for abuse.

- Thread: Bonded Nylon, Tex 70 (Size #69). It’s got that superior abrasion resistance that will let it glide through thick canvas layers and lock in super-strong seams.

- Needle: A Size 18/110 Jeans/Denim needle. That sharp, reinforced point is made to punch through dense fabric without skipping a beat (or a stitch).

- Stitch Length: Lengthen your stitch to around 3.5 mm. This gives you a strong seam without over-perforating the canvas, which can weaken it.

Start by putting the main body of the tote together. When you get to the corners or the spots where you’ll attach the straps, slow your machine down. This gives you more control and ensures every stitch is perfect. For the handles, use a box stitch—a simple square with an "X" through the middle—to anchor them securely to the bag. Maximum strength, guaranteed.

Project 2: Bringing a Leather Belt Back to Life

Fixing up a leather belt is a fantastic way to get comfortable working with one of the toughest materials out there. Whether you’re sewing a buckle back on or mending a split, you need a thread that won't wimp out against the dense hide.

Leather demands a thread with serious tensile strength, but it also has to slide through that tough material without snagging or fraying from friction.

Here's the thing with leather: every hole your needle makes is permanent. Precision is non-negotiable. A strong, smooth thread means you get it right the first time, without having to re-sew and risk weakening the belt. The right setup is what separates a clean, professional repair from a damaged piece.

Your Setup Guide:

- Thread: Once again, Bonded Nylon, Tex 70 is our hero. Its incredible strength and slick, bonded finish are just what you need for leatherwork.

- Needle: Go for a Size 18/110 Leather needle. It has a unique chisel-like point that slices through the leather, creating a clean path for the thread instead of just punching a hole.

- Machine Settings: Loosen your upper tension just a tad to help the thicker thread run smoothly. If you've got a walking foot, now is the time to use it! It will help feed the leather through evenly.

- Stitch Length: A longer stitch length of 4.0 mm is your friend when sewing leather.

If you’re re-stitching a buckle, try to use the existing holes as a guide. Take it slow and steady, keeping your stitches straight. A solid seam here means that buckle isn't going anywhere.

Project 3: Creating Durable Outdoor Upholstery

When you're making or mending outdoor cushions, you're not just fighting fabric—you're fighting the elements. Sun, rain, and mildew are constantly trying to destroy your work, and your thread is the very first line of defense. This is one of those times when UV resistance isn't a "nice-to-have," it's a must.

For this project, the goal is a weather-resistant cushion cover that won't fade, rot, or fall apart after just one season outside.

Your Setup Guide:

- Fabric: Use a marine-grade vinyl or a solution-dyed acrylic like Sunbrella. These fabrics are engineered from the ground up to live outdoors.

- Thread: Bonded Polyester, Tex 70. Honestly, this is the only real choice for outdoor gear. Its fantastic UV and mildew resistance means your seams won't turn brittle in the sun or grow mold.

- Needle: A Size 18/110 Universal or Jeans needle will work great with these types of fabrics.

- Stitch Length: Stick with a 3.5 mm stitch length for a seam that’s both strong and stable.

As you sew, give extra attention to the corners and anywhere you're installing a zipper—these are the biggest stress points. A little backstitching here goes a long way. Using bonded polyester also ensures your thread color stays true, so it will keep matching your fabric even after months of sun exposure.

Hopefully, these replicable project guides show you how pairing the strongest sewing thread with the right setup can take your work from feeling homemade to looking totally professional. With the support of bsewinn.com's custom machines and wealth of resources, you’ve got everything you need to tackle any heavy-duty challenge that comes your way.

Answering Your Questions About Strong Sewing Thread

Diving into the world of heavy-duty thread can feel like a big leap, and it's totally normal to have a few questions. I've been there! This little FAQ is designed to give you clear, no-nonsense answers to the most common head-scratchers, so you can solve problems quickly and get back to your project with confidence.

Can I Use Heavy-Duty Thread in My Regular Sewing Machine?

Most of the time, yes—but you have to be smart about it. The average home sewing machine can usually handle thread up to a Tex 70 weight, as long as you make a couple of critical adjustments.

First, you absolutely must switch to a larger needle. A size 16/100 or 18/110 is non-negotiable. Second, you'll need to loosen your upper tension to allow that thicker thread to glide through smoothly.

Keep in mind, though, that a standard machine's motor will really struggle with the thickest bonded threads or super dense materials like leather. For consistent, frustration-free results without burning out your machine, a heavy-duty or industrial model is always your best bet. At bsewinn.com, we specialize in custom machines built to handle these tough jobs effortlessly, taking all the guesswork out of it for you.

What Is the Difference Between Bonded Nylon and Bonded Polyester?

Think of it as choosing the right tool for a very specific job. Bonded nylon is the absolute workhorse; its strength and resistance to abrasion are second to none. This makes it the go-to for leatherwork, shoes, and any gear that's going to get rubbed and scraped constantly.

Bonded polyester, on the other hand, is the undisputed outdoor champion. Its biggest strength is its incredible resistance to UV rays, moisture, and mildew. If you're making boat covers, awnings, or patio cushions—anything that's going to live outside in the elements—polyester is really your only choice.

Here's the simplest way to remember it: if it's going to get a lot of friction, use nylon. If it's going to see a lot of sun, use polyester. Matching the thread's superpower to your project's environment is the secret to making something that truly lasts.

Why Does My Strong Thread Keep Shredding or Breaking?

Oh, the dreaded thread shred! This is one of the most frustrating things to deal with, but it almost always comes down to one of three culprits.

Nine times out of ten, your needle is just too small. The eye of a small needle creates a ton of friction as the thick thread is pulled through, and it literally saws the thread apart. Swapping to a larger needle should always be your first move.

If that doesn't work, check your upper tension. It's probably too tight. Heavy thread needs more breathing room to pass through the tension discs, so dial it back a bit. Lastly, slow down! Sewing too fast generates a surprising amount of heat, which can weaken and even melt synthetic threads. Take your foot off the gas, especially over thick layers, to keep everything running cool and smooth.

Do I Need to Use the Same Strong Thread in the Bobbin?

Yes, you one hundred percent do. For a seam to be truly strong and balanced, the thread in the needle and the bobbin must be the same. If you use a weaker thread in the bobbin, you're creating a literal weak link in the chain. Your seam will only ever be as strong as its weakest part.

When you're winding the bobbin, take your time and do it slowly and evenly. A nicely wound bobbin of heavy-duty thread will feed out of the case perfectly, preventing tangles and making sure your stitches are just as strong on the bottom as they are on the top.

Ready to take on your most ambitious sewing projects yet? At bsewinn.com, we've got the machines, the know-how, and the support to help you turn those big ideas into durable, professional-quality reality. Check out our huge collection of heavy-duty machines and supplies at https://www.bsewinn.com and start making things that are built to last.