If you’re serious about sewing thick, heavy materials, you’ll need the right tool for the job. A heavy-duty model with a powerful motor and a solid metal frame isn't just a "nice-to-have"—it's a must. Trying to force denim, leather, or multiple layers of canvas through a standard machine is a recipe for frustration, leading to skipped stitches and snapped needles. A true heavy-duty machine is built from the ground up for these kinds of tough projects. At bsewinn.com, we specialize in custom sewing machine designs engineered to empower you to create, and we're here to guide you through replicating tangible projects with the right tools and support.

Why Your Regular Machine Struggles with Heavy Fabrics

Ever felt like you're in a wrestling match with your sewing machine when you're working with something like denim, canvas, or upholstery fabric? It’s a super common roadblock for sewists who are ready to tackle more ambitious projects. That struggle is real because most standard home sewing machines are designed for lightweight cottons and flowy fabrics, not for punching through dense, tough layers.

Think of it like trying to drive a family sedan on a rugged, off-road trail. It might get you a little way down the path, but it just doesn't have the power, reinforced frame, or specialized tires to handle the rough terrain. A standard sewing machine is the sedan in this scenario; it just wasn't built for the "off-roading" that heavy fabrics demand.

The Core Differences in Power and Build

The main reasons your everyday machine throws in the towel come down to its motor and its skeleton.

- Motor Power: A standard motor just doesn't have the muscle (or torque, in mechanical terms) to consistently drive a needle through multiple layers of denim or a tough hide of leather. You'll hear it strain, slow down, or stop completely.

- Internal Frame: To keep them lightweight and affordable, many basic machines have plastic components inside. Under the stress of heavy fabrics, that plastic can flex and vibrate, throwing off your alignment and causing those dreaded skipped stitches.

- Presser Foot Pressure: If the presser foot can't hold the fabric down firmly enough, the material will bounce up and down with the needle—a frustrating problem known as "flagging." This leads to messy, uneven stitches.

This performance gap is exactly why the market for tougher machines is booming. The extra heavy-duty sewing machine market was valued at USD 1.2 billion globally, a number that's expected to nearly double by 2034. It's a clear sign of how essential these workhorses are in industries from automotive upholstery to heavy-duty apparel. You can dig into more data on the heavy-duty sewing machine market to see just how big their industrial role is.

At B-Sew Inn, we believe your creativity should never be held back by your equipment. Our custom sewing machine designs are engineered to be your "off-road truck" so you can tackle any project with total confidence.

But our commitment to empowering crafters doesn't end when you buy a machine. Through our huge library of online classes, training, and resources, we'll help you master the skills you need for any project, whether it's a custom leather bag or durable home décor. We're here to match you with the right machine and the extensive support to bring your vision to life.

What Really Makes a Sewing Machine "Heavy Duty"?

So, what's the secret sauce that separates a true powerhouse from a standard machine when you're looking for the best sewing machine for thick material? It’s definitely not just a sticker on the box. The real strength is under the hood—a whole team of beefed-up components engineered to tackle the tough stuff.

Once you know what these core parts are, you can see right past the marketing fluff and understand what a machine is truly capable of. You'll be able to confidently pick a machine that partners with your thick fabrics, instead of fighting against them.

The Unstoppable Force of a High-Torque Motor

The motor is the engine of your sewing machine, and in a heavy-duty model, it's a completely different animal. A standard motor is built for zipping along on lightweight fabrics like cotton. But throw a few layers of denim or leather at it, and it just doesn't have the raw punching power—the torque—to get the needle through without sputtering to a stop.

A high-torque motor, on the other hand, is all about muscle. It delivers a steady, powerful punch with every stitch, no matter how slow or fast you're going. This means it can drive the needle through thick canvas or tough vinyl without even breaking a sweat. It’s what keeps the motor from straining, overheating, or just giving up halfway through a seam, which is exactly where a less capable machine will fail you.

An All-Metal Frame for Rock-Solid Stability

Think about trying to hammer a nail while standing on a wobbly stool—you'd lose all your power and accuracy. Sewing works the same way. A lot of basic machines use plastic for their internal parts to keep the cost and weight down, but that creates a huge weak spot when you start working with heavy materials.

A true heavy-duty machine is built on an all-metal frame. This rigid internal skeleton is the solid foundation that absorbs all the vibrations from punching through dense fabrics. That stability is absolutely essential for preventing skipped stitches and keeping your stitch quality perfect, even when you're sewing fast.

This tough construction also means the machine is built to last. It can handle the stress of demanding projects for years and years without the internal parts flexing, bending, or getting knocked out of alignment.

Essential Features for Taming Tough Fabrics

Beyond the motor and the frame, a few other key features are critical for managing the bulk and texture of thick fabrics. These are the parts designed to grip, move, and make room for materials that would completely overwhelm a standard machine.

- Higher Presser Foot Lift: This is just how much space you can get between the presser foot and the needle plate. A machine with an extra-high lift makes it a breeze to slide a bulky quilt sandwich, thick layers of fleece, or a chunky bag seam right under the needle without a fight.

- Specialized Feed Systems: Your average feed dogs can slip and slide on materials like leather or vinyl, struggling to get a good grip. Heavy-duty machines often have more aggressive feed dog systems, sometimes with more points of contact, to pull fabric layers through evenly and stop them from shifting around. This is also where an accessory like a walking foot becomes a game-changer, adding a top-feeding mechanism for absolutely flawless results.

- Adjustable Presser Foot Pressure: This little dial is your secret weapon. It lets you fine-tune how hard the presser foot clamps down on your fabric. Cranking up the pressure helps you get a firm grip on slippery stuff like vinyl, while easing up on it lets lofty, thick fabrics feed through smoothly without getting squished flat.

Here at B-Sew Inn, our custom sewing machine designs are built with these critical features because we know they make all the difference. Our experts can walk you through our custom machine designs, making sure you find the perfect model for whatever you dream of creating. Plus, our extensive online classes and training and resources are there to help you master your new machine, empowering you to tackle any project with confidence.

How to Choose Your Heavy-Duty Sewing Companion

Picking the right machine to muscle through thick materials is a big decision, but it doesn't have to be a stressful one. The secret is to zero in on what really matters for the kinds of projects you dream of making, whether that’s a tough-as-nails canvas tote or a beautifully detailed leather clutch. Let's break it down and help you find a machine that feels like a true partner in your craft.

Your first big fork in the road is deciding between a mechanical workhorse and a smart, computerized model. Each one brings something different to the table when you’re sewing through dense, heavy fabrics.

Mechanical vs. Computerized Heavy-Duty Machines

Mechanical machines are the tried-and-true titans of the sewing world. I'm talking about those classic, no-nonsense models built with heavy-duty metal frames that keep them rock-steady on your table. Their biggest advantage is their beautiful simplicity. With fewer electronic components, there’s just less that can go wrong, making them incredibly dependable for pure, powerful stitching.

On the other hand, computerized machines offer a world of precision and ease. They come packed with a huge library of stitches, handy automated features like one-step buttonholes and needle threaders, and bright LCD screens that make adjustments a breeze. If your projects involve detailed work on thick materials—like flawless decorative topstitching on a vinyl jacket—a computerized machine gives you a level of control that's hard to beat.

The right machine isn't about which one is "better" in general, but which one is better for you. A leatherworker who just needs raw, unstoppable power might fall in love with a mechanical model. Meanwhile, a quilter wrangling bulky quilt sandwiches would probably appreciate the fine-tuned precision and stitch options of a computerized machine.

Here at B-Sew Inn, this is our specialty. Our experts can walk you through the pros and cons and even demo our custom sewing machine designs so you can feel for yourself how each type handles the fabrics you love. Our commitment is to empower you to find the perfect creative partner.

Evaluating Crucial Features for Tough Jobs

Once you've picked a side—mechanical or computerized—there are a few non-negotiable features for anyone serious about sewing machines for thick material. Thinking about how you'll actually use these will point you straight to the perfect model.

- Adjustable Speed Control: This is a lifesaver. It lets you slow way down for tricky curves or ultra-thick seams, giving you total control and helping you avoid snapped needles.

- Stitch Variety and Strength: Look for machines offering reinforced straight stitches and other utility stitches built for durability. A lot of the time, a simple straight stitch is all you need, but having strong, reliable options is a must.

- Essential Presser Feet: The availability of a walking foot is absolutely critical. This amazing accessory grips the top layer of fabric while the machine’s feed dogs grip the bottom, making sure all those layers move together as one perfect unit, with no shifting or puckering.

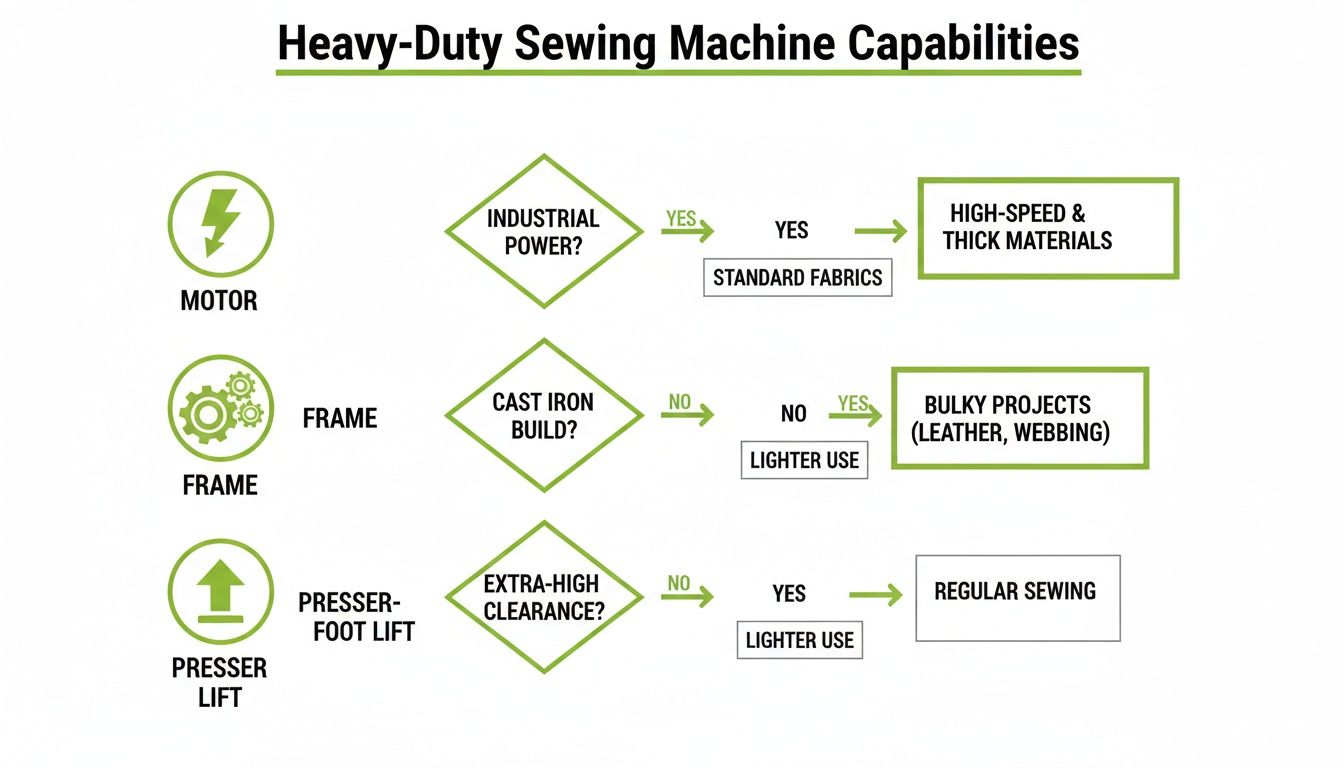

This decision tree gives you a visual on how the motor, frame, and presser foot lift are the core building blocks of a truly capable machine.

At the end of the day, it's that powerful motor, sturdy frame, and high presser foot lift working in harmony that lets you conquer any fabric you throw at it.

Matching Your Machine to Your Material

To make things even clearer, let's look at how specific machine features line up with the materials you want to sew. It really helps to visualize how your choice will play out in your actual projects.

Heavy-Duty Machine Feature Comparison

This table breaks down what you can generally expect from the three main categories of heavy-duty machines. It's a great starting point for seeing where your needs might fit.

| Feature | Mechanical Heavy-Duty | Computerized Heavy-Duty | Industrial/Semi-Industrial |

|---|---|---|---|

| Primary Strength | Raw power & durability | Precision & versatility | Speed & specialized power |

| Motor | Strong AC/DC motor | Powerful DC motor | High-torque servo/clutch motor |

| Stitch Options | Basic utility stitches | Wide variety of decorative & utility | Typically straight-stitch only |

| User Interface | Manual dials & knobs | LCD screen, push-buttons | Manual controls, function-focused |

| Best For | Leather, canvas, simple repairs | Quilting, detailed upholstery | Production work, upholstery shops |

As you can see, each type is engineered for a different kind of sewing experience. Making the right choice ensures your machine won't just handle what you're doing now, but will be ready to grow with you as your skills and ambitions expand. For an even deeper dive, check out our complete guide on how to choose a sewing machine that’s a perfect match for your creative style.

For a really solid and stable setup, which is so important when wrangling heavy fabrics, many sewers find it's worth choosing a sewing machine with a cabinet. A dedicated station cuts down on vibrations and gives you the space you need to maneuver those big, bulky projects.

Just remember, B-Sew Inn is more than a store—we're your creative partners. Through our extensive resources, online classes, and expert training, we're here to help you get the absolute most out of your machine, so it becomes a natural extension of your hands and your vision.

Essential Needles and Thread for Thick Fabrics

Having a powerful machine is a huge first step, but let's be honest—your needles and thread are the true front-line soldiers in the battle against thick fabrics. I like to think of them as the tires and fuel for your off-road truck; without the right setup, even the most powerful engine is just going to spin its wheels.

Choosing the right tools isn't just a friendly suggestion. It's the only way to prevent snapped needles, shredded thread, and those frustratingly uneven stitches that can ruin a heavy-duty project.

This is where understanding the small-but-mighty components of your setup really pays off. Once you know how they work together, you can turn a frustrating struggle into a smooth, professional process.

Decoding Sewing Machine Needles

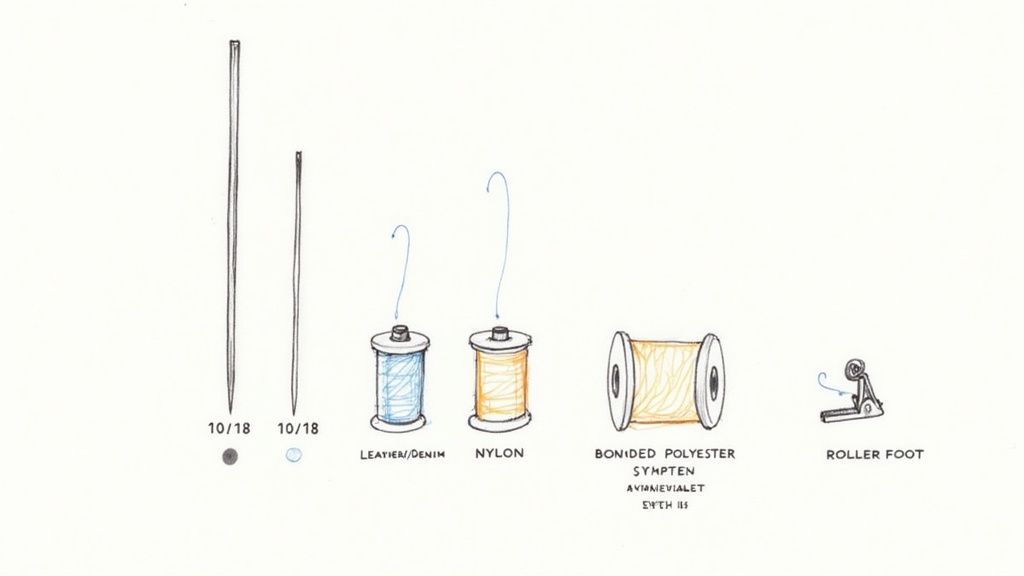

The needle is the very tip of the spear. Trying to use a needle meant for lightweight cotton on a piece of leather is a recipe for disaster. Heavy-duty needles are physically thicker and stronger, but they also have specialized points made to cleanly pierce dense materials instead of snagging or punching ragged holes.

When you're working with sewing machines for thick material, you have to get both the size and type right.

- Needle Size: You’ll want to look for larger sizes, like 100/16 or 110/18. These numbers mean the needle shaft is thicker and more robust, so it can handle the force needed to get through canvas or multiple quilt layers without bending or breaking.

- Needle Type: The point is just as important as the size. Denim (or Jeans) needles have a super sharp, slender point designed to cut through tightly woven fabrics. Leather needles, on the other hand, have a wedge-shaped point that literally slices through hides without tearing them. To really get a feel for how each type works, you can check out our detailed guide on the different types of sewing machine needles.

The Strongest Threads for Durable Seams

Just like a weak needle will break, a flimsy thread will snap under the strain of sewing heavy materials. Your standard all-purpose cotton or polyester thread just doesn't have the tensile strength to hold up. For projects that need to be tough—think bags, upholstery, or outdoor gear—you need a thread engineered for strength.

Your best bets are usually bonded polyester or heavy-duty nylon. These threads are incredibly strong and built to resist abrasion, UV rays, and moisture, which makes them perfect for anything that will see a lot of wear and tear.

The need for durable thread and powerful machines isn't just for hobbyists. In the automotive industry, the reliance on industrial sewing machines for tough materials like leather seats has driven huge market growth—a forecasted increase of USD 1.34 billion between 2023-2028. You can discover more insights about this industrial market growth on Technavio.com.

Indispensable Accessories for Flawless Feeding

Okay, so you've got the right needle and thread. But thick layers can still shift, pucker, and slide around as they move under the presser foot. This is where a few specialized accessories become your absolute best friends, making sure every layer feeds through the machine evenly.

- Walking Foot: This is a non-negotiable for me. A walking foot has its own set of feed dogs that work with your machine's feed dogs to grip the top layer of fabric. It moves the top layer at the exact same pace as the bottom, which is the secret to perfectly matched seams on quilts, vinyl, and other tricky fabrics.

- Roller Foot: If you’re working with "sticky" materials like leather, faux leather, or vinyl, a roller foot is a game-changer. Instead of a flat bottom that can drag and cause skipped stitches, it has tiny rollers that glide right over the fabric's surface.

At B-Sew Inn, we offer online classes and training to help you master these tools. We are committed to empowering you with the skills to tackle any thick material with results that look totally professional.

Mastering Techniques for Sewing Heavy Materials: A How-To Example

Alright, you’ve got the right machine, the perfect needles, and the toughest thread. Now for the fun part. This section is a comprehensive how-to guide, showcasing a tangible example that you can replicate. We'll walk through creating a simple, sturdy canvas tote bag—a perfect project to master heavy-duty skills.

Think of this as your own mini-workshop. The skills you pick up here are the same foundational techniques we teach in our B-Sew Inn online classes, all designed to empower you with the confidence to replicate this project and tackle any other that catches your eye.

Prepping Your Machine and Fabric

Before you even think about hitting that foot pedal, a little prep work is your best friend. Sewing thick materials is way less forgiving than lightweight cotton; taking a few minutes to set up properly will save you from major headaches down the road.

First things first, set a longer stitch length. I usually go with something between 3.0 mm and 4.0 mm. A longer stitch isn’t just stronger; it helps the machine feed those bulky layers through more smoothly. Plus, it prevents you from creating a dense line of weak perforation points, which is a real problem on materials like vinyl or leather.

Next, take your foot off the gas. If your machine has a speed control slider, use it. Sewing at a slower, more controlled pace gives the motor the torque it needs to punch through every layer, every single time. It also gives you more control to guide the fabric without getting off track.

Handling Bulky Seams and Intersections

The biggest hurdle on a project like a canvas tote is dealing with the bulk where seams cross or where you attach thick webbing for the handles. I call these "fabric mountains." This is the exact spot where a machine is most likely to stall, skip stitches, or even snap a needle clean off.

To get over these humps, a tool called a hump jumper (or even just a folded-up piece of cardboard) is a lifesaver. As your presser foot starts climbing a thick seam, it tilts backward. By placing the hump jumper behind the needle, you level out the foot. This lets the machine glide evenly over the hump instead of fighting its way uphill.

And if you're working with multiple shifting layers, a walking foot is non-negotiable. It grips the top and bottom fabric layers at the same time, pulling them through evenly. If you're new to this amazing accessory, we have a handy guide on how to use a walking foot that breaks it all down.

These aren't just techniques for us hobbyists, by the way. The entire industrial sewing machine market was built on the need to handle tough, technical textiles—functional fabrics like Vinyon and Modal that are used in everything from construction to high-performance gear. In fact, that market is projected to hit USD 7.44 billion by 2032, driven by the need to stitch these innovative materials.

Troubleshooting Common Frustrations

Even with the best prep, sometimes things just go wrong. Knowing how to fix common issues on the fly is what makes you a truly confident sewer, especially when you’re working with demanding fabrics.

- Skipped Stitches: Nine times out of ten, this is a needle issue. Your first move should always be to pop in a brand-new, correct-sized needle (like a 100/16 Denim needle). If that doesn't fix it, completely re-threading the top thread and the bobbin usually does the trick.

- Shredding Thread: This is almost always a sign of too much friction. Make sure you're using a topstitching or denim needle with a larger eye. Also, check that your thread tension isn't cranked up too high—ease it back a bit.

- Uneven Feeding: If your fabric layers are slipping and sliding, a walking foot is your number one solution. It’s also worth checking your presser foot pressure; you may need to adjust it for the fabric's thickness.

Getting these hands-on skills down is what separates a frustrating afternoon from a joyful and productive one. Here at B-Sew Inn, we're all about empowering you with the support you need, from our custom sewing machine designs to the online training and extensive resources that help you use them like a pro.

More Than a Machine, You're Part of the Family

Let's be honest, the real creative journey starts after you get your new machine home. That's when the questions pop up and the big ideas start brewing. At B-Sew Inn, we get that, and our support for you doesn't stop at the checkout counter. Our commitment is to empower crafters through our custom sewing machine designs, emphasizing the extensive support offered via online classes, training, and resources.

It all starts with our custom-designed machines, built from the ground up to power through denim, canvas, and leather like a dream. But owning one of our heavy-duty sewing machines for thick material is just step one. Real skill and confidence come from learning and having someone to turn to when you're stuck, and that’s exactly what we provide.

Get the Most Out of Your Machine

We want every stitch you make to be a happy one. Whether you're just starting out or tackling advanced techniques, we've got the tools to help you succeed.

- Online Classes and Training: Jump into workshops led by passionate experts. They'll walk you through everything from the basics to the really cool, advanced features of our custom machines.

- A Support Team That Actually Sews: Got a question? Hit a snag? Our team is here for you. They know these machines inside and out and can help you troubleshoot any challenge that comes your way.

- Tons of Online Resources: Get inspired with our huge library of online tutorials and project guides. They're available 24/7 for whenever creativity strikes.

We’re not just a store—we’re a community of people who love to create. We're here to help you find joy and success in your craft, long after you've taken your machine home.

When you choose B-Sew Inn, you're not just buying a product; you're joining a family that's just as passionate about sewing as you are. We provide the machine, the know-how, and the support system—everything you need to turn your boldest ideas into reality. Your success is what makes us tick, and we’re here to help every step of the way.

Your Top Questions Answered

When you're diving into the world of heavy-duty sewing, it's natural for a few questions to pop up. Whether you're trying to pick out your first real workhorse machine or just looking to get your technique down, I've been there. Let's tackle some of the most common questions we hear from crafters just like you about sewing machines for thick material.

Can I really use my regular sewing machine for denim or leather?

I get this one a lot. While you might get away with a single hem on some lightweight denim, you're really pushing your luck on bigger projects. Your standard home machine just doesn't have the motor strength or the sturdy frame needed for those dense fabrics. It's a recipe for skipped stitches, snapped needles, and a burnt-out motor.

Think of it like trying to chop firewood with a kitchen knife. You might make a dent, but you’re going to ruin the knife. A true heavy-duty machine is built from the ground up for this kind of tough love.

What’s the single most important feature to look for in a heavy-duty machine?

An all-metal frame is non-negotiable, and a high presser foot lift is a must-have, but if I had to pick just one thing, it's the motor. Hands down, the motor is the heart of the machine.

A high-torque motor gives you that raw, consistent piercing power you need to drive a needle through layer after layer of canvas or leather without even flinching. Without a powerful motor, the sturdiest-looking machine will grind to a halt when the going gets tough.

Your machine's motor is its heart. A strong, reliable motor ensures you can tackle any project with confidence, knowing your machine won't give up halfway through a critical seam. This is a core feature in all B-Sew Inn custom designs.

How do I stop my needles from breaking when I sew thick fabric?

Ah, the dreaded snap! A broken needle is almost always a sign that something's off—either the needle itself is wrong for the job, or you might be accidentally fighting the machine.

Here’s a quick checklist to keep your needles intact:

- Pick the Right Tool for the Job: Go for a bigger needle, like a 100/16 or 110/18. Crucially, make sure the type matches your fabric. Use a Denim needle for denim, a Leather needle for leather—they're designed with special points for a reason.

- Seat It Properly: When you put in a new needle, make sure it's pushed all the way up and tightened securely. A wobbly needle is a disaster waiting to happen.

- Don't Force It: This is a big one. Let the machine's feed dogs do all the work of pulling the fabric through. Your job is just to guide it straight. Pushing or pulling the fabric will bend the needle, and... snap.

- Ease Off the Gas: Slow your sewing speed way down, especially when you’re coming up on a thick seam or crossing over multiple layers. This gives the motor time to punch through cleanly.

Here at B-Sew Inn, we know that getting the machine is just the first step. That’s why we have a huge library of online classes and training resources designed to help you build the skills and confidence to create amazing things. We’re here for you, every step of the way.

Ready to conquer any fabric? Explore the custom-designed heavy-duty models at B-Sew Inn and find the perfect machine to bring your most ambitious projects to life. Shop our sewing machines now.