We've all been there. You're excited about a new project—maybe some sturdy denim jeans or a rugged canvas tote—and you bring it to your trusty sewing machine. But instead of a clean, satisfying stitch, you get that awful shudder. The needle protests, maybe even snaps. You're left with skipped stitches and a whole lot of frustration.

It’s a familiar story for so many of us. Your standard sewing machine just isn't cut out for the heavy lifting. To really bring those ambitious ideas to life, you need something with more muscle: a purpose-built sewing machine for thick fabric designed with a powerful motor and a rock-solid frame.

Conquering Heavy Materials: Your Guide to Thick Fabrics

Working with materials like leather, upholstery fabric, or even just multiple layers of quilting cotton demands more than just a bit of patience. It requires the right tool for the job. A machine that floats effortlessly over chiffon will quickly hit a wall when it meets the dense, unforgiving nature of these tougher textiles. The motor might stall out, the frame can start vibrating like crazy (killing your stitch quality), and the feed dogs might give up on moving the project along evenly.

This guide is here to fix that. We’re going to walk through all the key features that make a heavy-duty machine different, from its guts to the specialized accessories that promise a perfect finish. Think of it like swapping your family sedan for a powerful pickup truck. Both are great at what they do, but only one has the torque and build to haul a heavy load.

Your Roadmap to Success

We'll lay out a clear path to help you pick, set up, and master the perfect sewing machine for thick fabric. This guide serves as a comprehensive "how-to" for creating various designs, showcasing tangible examples that crafters can replicate. We'll be covering:

- Understanding the Anatomy: What really makes a machine "heavy-duty"? We'll look at everything from motor power to the frame construction.

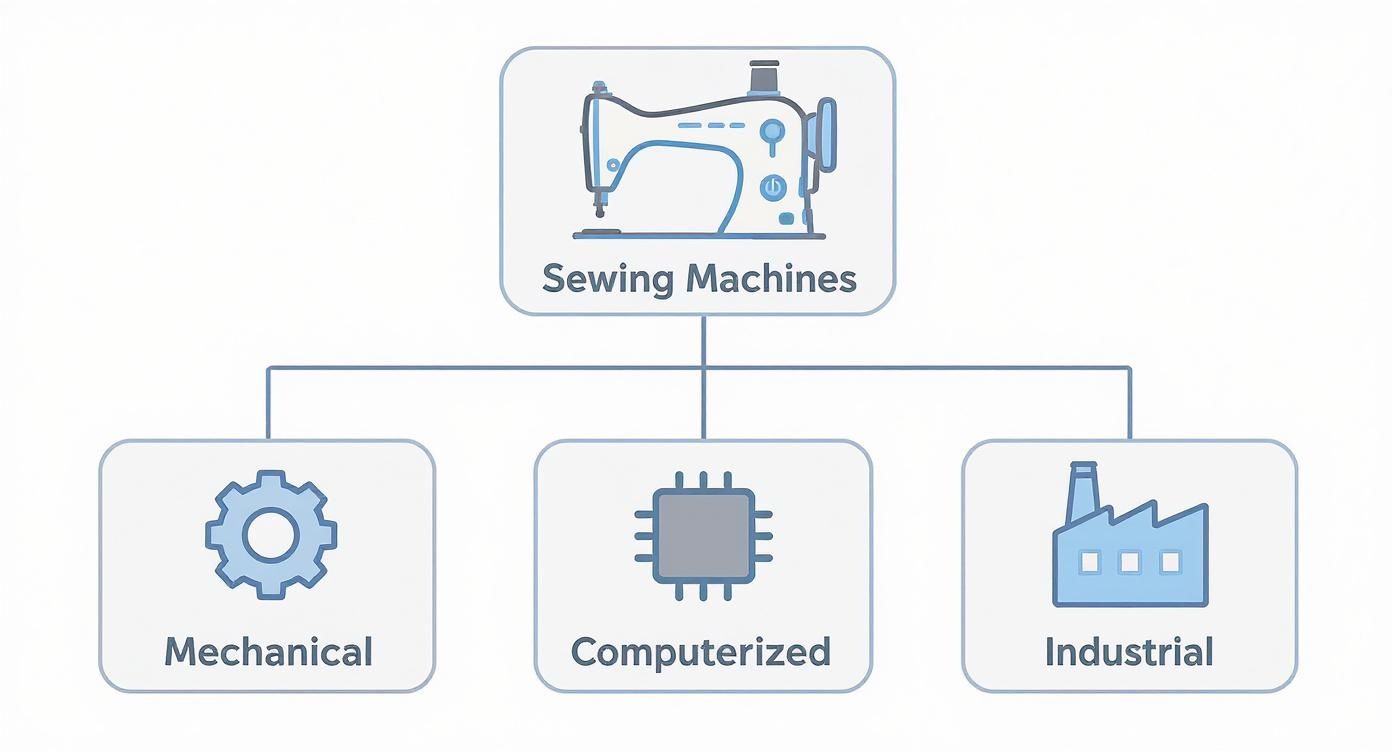

- Choosing the Right Type: I'll break down the differences between mechanical, computerized, and industrial-style machines and where each one shines.

- Essential Setup: Learn how to properly match your needles, thread, and tension settings to get those professional-looking seams.

- Mastering the Techniques: We'll get into practical tips for sewing everything from rugged bags to your own custom upholstery.

Here at bsewinn.com, we are committed to empowering crafters by providing not just better tools, but the know-how to use them. Our custom sewing machine designs are engineered specifically for the projects that inspire you, whether that's an intricate quilt or durable outdoor gear.

Our commitment doesn't stop when you buy the machine. We back it up with extensive support, including online classes and training resources, and a whole community of fellow sewers. This guide is your first step on that journey, giving you the solid foundation you need to make your most ambitious creative visions a reality.

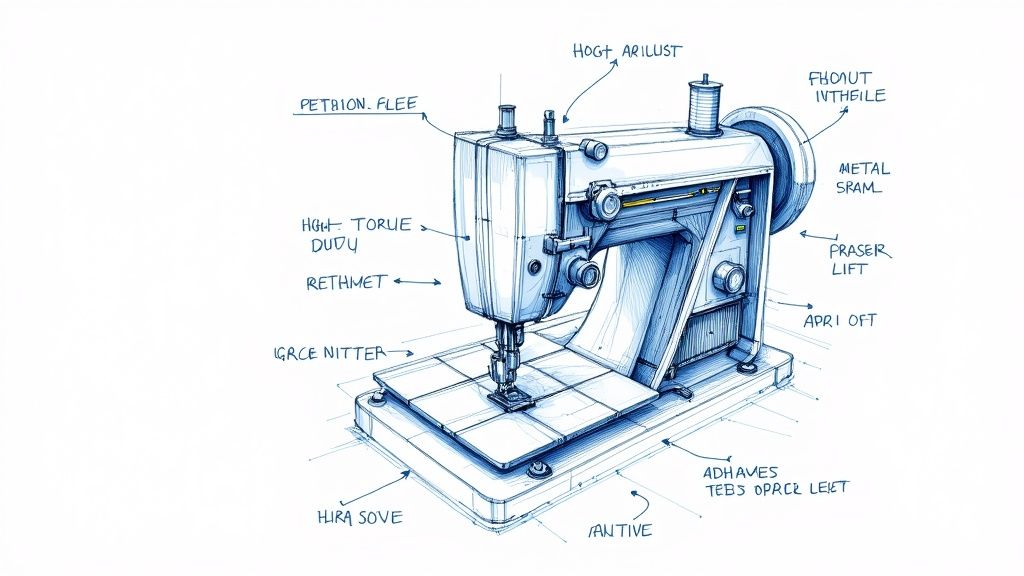

What Makes a Heavy Duty Sewing Machine Different

When you're staring down a pile of denim seams or a stiff sheet of canvas, you quickly realize that not just any sewing machine is going to cut it. To really get why a heavy-duty model powers through where a standard one sputters out, we need to look under the hood. This isn't just clever marketing; it’s about pure, raw engineering built for strength, stability, and control.

Think of the motor in a sewing machine for thick fabric like the engine in a pickup truck. A standard machine has an engine more like a little sedan—great for cruising along on smooth, lightweight cottons. But the moment you hit the steep hill of upholstery vinyl or thick wool, that little motor is going to strain and stall. A heavy-duty motor, on the other hand, is built for torque.

That extra torque gives it the muscle to punch the needle through layer after layer, consistently and without slowing down. It's this steady, forceful punch that prevents the skipped stitches and snapped needles that drive you crazy when you push a regular machine past its comfort zone.

The Unshakeable Foundation of an All-Metal Frame

While the motor brings the brawn, the frame provides the backbone to handle it. You'll find that true heavy-duty machines are almost always built with a full metal interior frame. This isn't just about making it last longer; it's a critical part of its performance. The metal chassis acts like a rigid skeleton, absorbing the intense vibrations from that powerful motor and the impact of the needle hitting dense material.

Without that solid foundation, the machine would shake and rattle all over your table, leaving you with messy, uneven stitches. A plastic frame just can't provide that kind of stability, which leads to frustrating results and can even damage the machine over time. The all-metal construction is what guarantees every stitch lands exactly where you want it, even when you're sewing at top speed.

"A machine's stability is directly proportional to its ability to produce a perfect stitch under stress. An all-metal frame is the non-negotiable anchor that allows a powerful motor to do its job without compromising stitch quality."

Here at bsewinn.com, we embrace this commitment to empowering crafters through our custom sewing machine designs. Our machines are engineered with beefy frames and high-torque motors—to give you the dependable performance you need to tackle those tough materials with confidence, supported by our extensive training and resources.

Critical Features That Make a Real Difference

Beyond the core duo of the motor and frame, a few other features are absolutely essential for sewing thick fabrics without a fight. These parts all work together to manage the bulk and heft of bigger projects, turning what could be a wrestling match into a smooth, creative flow.

- High Presser Foot Lift: This gives you that extra bit of clearance under the needle, making it so much easier to slide a bulky quilt sandwich or a thick bag strap into place. A low lift can make just starting a project a massive headache.

- Advanced Feed Dog System: Your standard feed dogs often slip and struggle to get a good grip on heavy fabric. Heavy-duty machines usually have more aggressive or wider feed dogs (sometimes called a box feed system) to pull the material through evenly and stop it from puckering.

- Generous Throat Space: The "throat" is simply the workspace to the right of your needle. A larger throat space is a game-changer for big projects like quilts, coats, or upholstery. It gives you room to maneuver without everything getting bunched up and impossible to control.

These features aren't just nice-to-haves; they're must-haves for getting professional results and keeping your sanity. When you're looking at a sewing machine for thick fabric, try to look past the fancy stitch counts and focus on these mechanical workhorses. They’re the real proof that a machine is built for serious sewing.

Comparing the Best Machine Types for Heavy Fabrics

Picking the right sewing machine for thick fabric really comes down to what you’re making, how much space you have, and your budget. It’s easy to get lost in all the options, but not all "heavy-duty" machines are built the same. Understanding the real differences between the main players is the secret to choosing a machine that will fuel your creativity, not fight against it.

Let's break down the three main contenders for sewing heavy fabrics.

Heavy-Duty Mechanical Machines: The Reliable Workhorses

Think of a heavy-duty mechanical machine as your classic, rugged pickup truck. It won’t have a fancy touchscreen or hundreds of decorative stitches, but it has one job, and it does that job exceptionally well: delivering raw, consistent power. Sewists love these machines for their straightforward, no-fuss attitude.

You'll find dials and levers instead of digital screens, which makes them incredibly durable and often easier to service yourself. The all-metal internal parts are built to last, giving you the brute force needed to drive a needle through dense canvas, stacks of denim, or multiple quilt layers without even flinching. For anyone who values pure power and durability over extra bells and whistles, a mechanical machine is the perfect partner in crime.

Heavy-Duty Computerized Machines: Precision Meets Power

If a mechanical machine is the classic truck, a heavy-duty computerized machine is its modern cousin—still tough, but loaded with smart features. These machines blend the powerful motor and robust build of a mechanical model with the precision and convenience of modern tech. For many sewists, this combo is the best of both worlds.

Imagine push-button controls, automatic thread tension that adjusts on the fly, and a needle that always stops in the down position for perfect pivots. These little luxuries take a lot of the guesswork out of sewing, letting you focus on your craft instead of fiddling with settings.

For projects that demand perfect stitch consistency, like topstitching on a leather bag or quilting an intricate pattern, the regulated stitch control of a computerized machine is a game-changer. It makes sure every single stitch is identical, giving you that professional finish that's so hard to get right manually.

Industrial and Semi-Industrial Machines: The Ultimate Powerhouses

Now we're getting into the big leagues. Industrial and semi-industrial machines are the undisputed champs of sewing thick, challenging materials. These aren’t your average home sewing machines; they are specialized beasts built for speed, efficiency, and relentless performance. Many are designed to do just one thing—like a straight stitch—but they do it flawlessly on the most demanding fabrics you can throw at them.

An industrial sewing machine for thick fabric can plow through materials that would completely destroy a domestic machine, from thick leather hides to multiple layers of heavy-duty sailcloth. The industrial sewing machine sector is a huge part of the global market, valued at USD 3.6 billion, which shows just how vital these powerhouses are in professional settings. You can discover more insights about the industrial sewing machine market and its projected growth.

Heavy-Duty Sewing Machine Type Comparison

Choosing the right type is all about matching the machine's strengths to your creative goals. To make it a little easier, I've put together a table to compare the three categories head-to-head.

| Feature | Heavy-Duty Mechanical | Heavy-Duty Computerized | Industrial/Semi-Industrial |

|---|---|---|---|

| Primary Strength | Raw power and durability | Precision and convenience | Unmatched speed and power |

| Best For | Denim, canvas, basic upholstery | Quilting, leatherwork, topstitching | Professional production, very thick materials |

| User Experience | Manual, hands-on control | Automated features, easy to use | Specialized, high-learning curve |

| Stitch Options | Basic utility stitches | Wide variety of stitches | Often single-purpose (e.g., straight stitch) |

| Cost | Most affordable | Mid-range to high-end | Highest initial investment |

| Maintenance | Simple, often user-serviceable | Requires professional servicing | Needs regular professional maintenance |

This chart should give you a clearer picture of where each machine shines. Whether you're a weekend warrior tackling your first pair of jeans or a pro churning out leather goods, there's a machine built just for you.

At bsewinn.com, we know every crafter's needs are different. That’s why we offer custom sewing machine designs that fit these different categories, ensuring you get the right tool for your specific passion. Our online classes and training resources are here to help you master whichever machine you choose, so you can tackle those ambitious projects with confidence.

Your Setup for Success: Needles, Thread, and Tension

Having a powerhouse of a machine is a great start, but that's all it is—a start. To turn that raw power into beautiful, strong stitches, you need to get your setup just right. Think of it like a high-performance car. You wouldn't slap on cheap, economy tires and expect it to hug the corners, right? It’s the same with your sewing machine for thick fabric; it needs the right needle, thread, and tension to truly shine.

This trio—needle, thread, and tension—is where the real magic happens. Nailing the balance between these three is the secret to seams that not only look fantastic but are tough enough to last. If you ignore them, you're setting yourself up for skipped stitches, shredded thread, and a whole lot of frustration, no matter how beefy your machine is.

This chart breaks down the main categories of sewing machines out there, which can help you see where your heavy-duty model fits into the bigger picture.

As you can see, all machines sew, but they branch off into distinct classes—Mechanical, Computerized, and Industrial—each built for different demands and capabilities.

Choosing the Right Needle for the Job

Your needle is the tip of the spear, and going into battle with the wrong one is a recipe for disaster. A standard universal needle will just bend, break, or dull instantly against something like canvas or leather. For the heavy stuff, you absolutely need a needle that’s built for the abuse.

Think about it this way: you wouldn't try to cut a steak with a butter knife. The same logic applies here. Each type of needle has a unique point and shaft specifically engineered for a certain kind of material.

- Denim (or Jeans) Needles: These are the workhorses. They have an incredibly sharp, reinforced point and a beefy shank made to punch through tightly woven fabrics without batting an eye. They’re a must-have for layers of denim, canvas, or heavy twill.

- Leather Needles: These are clever. Instead of a sharp point, they have a wedge-shaped tip that cleanly slices a tiny hole in leather or vinyl, rather than piercing it. This stops the material from tearing and creates a perfect opening for the thread.

- Topstitching Needles: These have a much larger eye and a deeper groove along the shaft. This design gives thicker topstitching thread the space it needs to move freely, preventing it from fraying or snapping under pressure.

Here’s a golden rule I always follow: always start a new project with a fresh needle. They dull much faster than you’d think, especially on tough materials. A dull needle is the culprit behind skipped stitches, fabric pulls, and unnecessary strain on your machine.

Pairing Your Project with Heavy-Duty Thread

Just as crucial as the needle is the thread holding it all together. Your standard all-purpose thread just doesn't have the muscle for this kind of work. It will shred and snap from the friction and tension, leaving you with weak seams that are doomed to fail.

For a tough sewing machine for thick fabric, you need thread that can pull its own weight.

- Heavy-Duty Polyester Thread: This is my go-to for almost any heavy project like upholstery, canvas bags, or outdoor gear. It's incredibly strong, stands up to UV rays and moisture, and has just a tiny bit of stretch for added durability.

- Nylon Thread: When you need something truly bombproof for leather goods or tactical gear, bonded nylon is the answer. It’s exceptionally strong and resists abrasion like nothing else, making it perfect for projects that will see a ton of wear and tear.

To make sure you're armed and ready for any fabric, take a look at our detailed guide that covers the different types of sewing machine needles. It’s a great resource for matching the perfect needle to any material you can think of.

Demystifying Thread Tension

Tension is the final piece of the puzzle, and honestly, it’s the one that trips people up the most. When your tension is right, the top and bobbin threads lock together perfectly in the middle of the fabric layers. That’s what creates a strong, balanced stitch.

When it’s off, the problems are obvious. If the top tension is too tight, you’ll see little dots of the bobbin thread peeking through on top. If it’s too loose, you’ll get ugly loops of the top thread on the bottom of your fabric.

The fix is simple. Grab a scrap of your project fabric and sew a test line. Look closely at both sides. A perfect stitch should look identical on the top and bottom. If you see loops or knots, make a tiny adjustment to your top tension dial—just one number at a time—and test again. Keep doing this until your stitches are perfectly balanced. Taking a minute to do this now will save you from major headaches later.

Practical Sewing Techniques for Thick Fabrics

https://www.youtube.com/embed/SLlZ18m_wMs

Alright, you’ve got your machine tuned up and ready to go. Now for the fun part: putting all that power and precision to work on a real project. Knowing your way around a sewing machine for thick fabric is one thing, but the real magic happens when you master the techniques that transform tough materials into something amazing. This section serves as a how-to guide, with tangible examples of designs you can replicate.

It's no surprise that more and more people are tackling these materials; the global market for heavy-duty sewing machines was valued at USD 3.82 billion and is only expected to grow. People want to create durable, lasting goods, and you can read the full research about this market trend if you're curious.

Creating Durable Seams on Denim

When you're sewing denim, one word should be on your mind: strength. Think about your favorite pair of jeans. That classic flat-felled seam isn't just for show; it's a workhorse. It cleverly encases the raw fabric edges to stop them from fraying while adding a second row of stitching for serious reinforcement.

To create this replicable design element, you start with a standard seam. Next, you’ll trim one side of the seam allowance. Then, just fold the wider side over the trimmed edge, press it flat, and stitch it down close to the fold. It takes a steady hand and a machine that won't flinch when punching through multiple layers of denim.

Working with Leather and Vinyl

Leather and vinyl are a completely different ballgame. These materials don't forgive mistakes—every single hole your needle makes is there for good. This means you have to get it right the first time. For a project like a custom leather tote bag, I always recommend a longer stitch length, somewhere in the 3.5mm to 4.0mm range. This reduces the number of holes, which keeps the material strong and prevents creating a perforated line that’s just begging to tear.

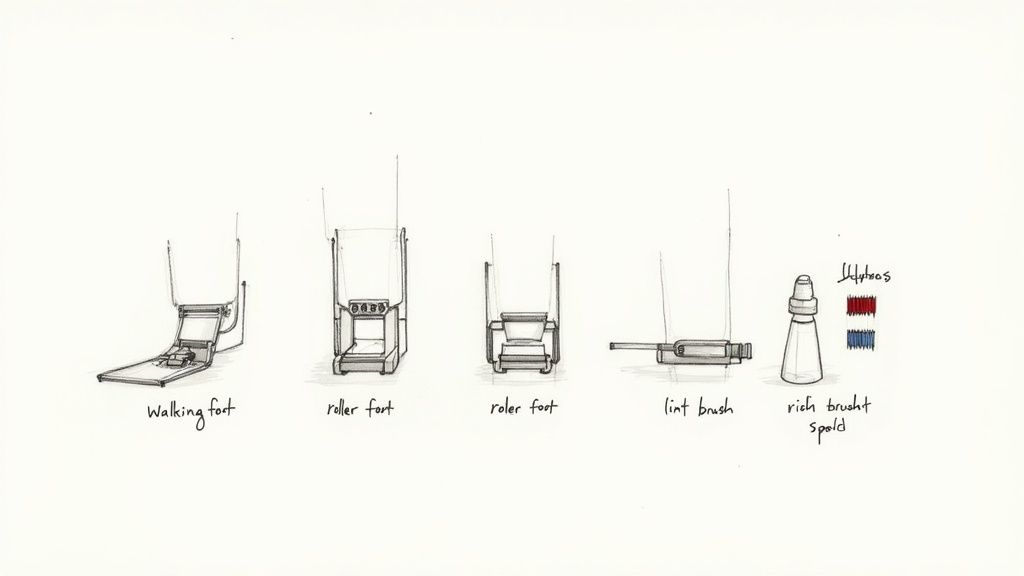

Another golden rule: step away from the pins! They leave permanent marks. Use binder clips or special sewing tape to hold your pattern pieces together instead. A non-stick Teflon foot or a roller foot is also a non-negotiable. It'll glide right over the sticky surface of vinyl or leather, where a standard foot would just drag and create a mess of puckered stitches.

This is where the bsewinn.com philosophy truly shines. Our custom sewing machine designs are engineered specifically for these demanding tasks, providing the power and precision needed for flawless results on materials like leather and denim. We empower crafters with the tools and support to achieve professional-level results.

Managing Bulky Upholstery Projects

Upholstery projects often feel like you're trying to sew a sandwich made of thick fabric, fluffy batting, and cording. The name of the game here is managing all that bulk and making sure every layer feeds through evenly. For a replicable project like a box cushion, your best friend is a walking foot.

A walking foot is an absolute game-changer. It has its own set of feed dogs that work in perfect harmony with your machine’s feed dogs, gripping the top layer of fabric and moving it along at the exact same speed as the bottom layer. This simple action prevents that frustrating shifting and puckering that can ruin a bulky project. If you want to see it in action, check out our guide on how to use a walking foot for all the details.

Your Partner in Craftsmanship

These techniques are the foundation for creating beautiful, long-lasting items from all kinds of heavy materials. But we know that having the right machine is just the beginning. That's why our online classes and training resources at bsewinn.com offer detailed, step-by-step video tutorials covering these exact methods. We’re here to give you the skills and confidence to take on those ambitious projects you've been dreaming of.

Essential Accessories and Machine Maintenance Tips

Owning a powerful sewing machine for thick fabric is just the beginning. The real magic—and the key to protecting your investment—lies in having the right accessories and a consistent care routine.

Think of it this way: a chef needs more than just a good stove; they need sharp knives, the right pans, and specialized utensils. For us, a few key accessories can turn a frustrating struggle with tough materials into a smooth, professional-looking project. These tools are your secret weapons, designed to solve the unique problems that heavy fabrics throw at you.

Must-Have Presser Feet for Tough Materials

Your standard presser foot is a jack-of-all-trades, but when you're working with heavy-duty materials, you need a specialist. Investing in the right feet will give you a night-and-day difference in stitch quality and control.

-

The Walking Foot: This is the undisputed champion for sewing through thick or slippery layers. It has its own set of feed dogs that grip the top layer of fabric, moving it in perfect sync with the bottom layer. No more annoying shifting or puckering when you're quilting, working with canvas, or tackling upholstery. It's an absolute game-changer.

-

Roller and Teflon Feet: Ever tried sewing leather or vinyl with a standard metal foot? It’s a sticky, frustrating mess. A roller foot glides over tacky surfaces with tiny rollers, while a Teflon foot has a non-stick coating that lets it slide effortlessly. Both are essential for getting those smooth, even stitches on demanding fabrics.

Equipping your machine with the right presser foot is like putting the right tires on a car. It gives you the grip and control you need to handle any terrain, whether it's the bumpy layers of a quilt or the slick surface of vinyl.

A Simple Maintenance Checklist for Your Machine

Sewing thick fabrics creates a ton of lint and dust—way more than you'd think! This fluff can quickly clog your machine, leading to tension problems and skipped stitches. A simple, regular maintenance routine is the best way to keep your workhorse running like new.

Keeping machines in top shape is a massive priority in the global textile industry. Just look at the Asia-Pacific region, which holds over 40% of the heavy-duty sewing machine market. All those machines, churning out billions in textiles from places like China, rely on diligent maintenance to handle the workload. You can explore more data on the global sewing machine market to get a sense of the scale.

Key Maintenance Tasks

-

Regular Cleaning: After every couple of projects, take a minute to brush the lint out of the bobbin case and feed dogs. This tiny step prevents buildup that can mess with your stitch quality. For a more detailed guide, check out our post on how to clean your sewing machine.

-

Proper Oiling: A well-oiled machine is a happy, quiet machine. Check your manual to find the oiling points and use just a drop or two of high-quality sewing machine oil. It keeps all those metal parts moving freely without friction.

-

Frequent Needle Changes: A dull needle is your worst enemy. It causes skipped stitches, pulled threads, and can even damage your fabric. I make it a habit to change my needle after every 8-10 hours of sewing, or at the start of any new project. It’s a cheap and easy way to avoid a lot of headaches.

Sticking to these simple tips won't just improve your sewing—it will extend the life of your machine, ensuring it’s always ready for whatever creative challenge you throw at it next.

Ready to Tackle That Big Project?

You've made it! After digging into what really makes a machine tough enough for heavy fabrics—from the motor's horsepower and a rock-solid frame to dialing in the right needles, thread, and tension—you're in a great spot. You now know what to look for and how to get set up for success. But honestly, this is just the fun beginning.

Here at bsewinn.com, our mission is to be your partner in creativity. We are committed to empowering crafters through our custom sewing machine designs and the extensive support we offer via online classes and training resources.

It's More Than Just a Machine

We pour our hearts into designing custom machines that are built for the kind of ambitious projects you've been dreaming about. Whether you're picturing a rugged canvas duffel bag or finally tackling that custom upholstery job, our machines have the guts to bring your vision to life without a single hiccup. Think of us as providing the solid foundation, so your creativity has room to really take off.

For us, empowering crafters is a two-part mission: provide exceptional tools, then give you the know-how to master them. We’re here to support every step of your journey, from that first spark of an idea to the final, perfect stitch.

To make sure you get the absolute most out of your machine, we've built a whole ecosystem of resources to build your skills and confidence. It's not just about having the right gear; it's about knowing what to do with it.

- Online Classes: Want to really nail a specific technique? Our expert-led video classes are available anytime you are, letting you dive deep at your own pace.

- In-Depth Training: Ready to move past the basics? We've got comprehensive tutorials that break down those intimidating, complex projects into easy-to-follow steps.

- Extensive Resources: Stuck on a problem or just looking for your next idea? Our library of articles, guides, and tips is your go-to spot for troubleshooting and inspiration.

We'd love for you to take a look around at our custom machine designs and training resources. It’s all about finding the perfect tools and the unwavering support you need to bring those challenging, imaginative projects to life. Your next great creation is just waiting for you to get started.

Ready to start your next project with total confidence? Explore our collection of custom-designed sewing machines and empowering online classes at B-Sew Inn. You can find the perfect tools to bring your creative vision to life at https://www.bsewinn.com.